Table of Contents

Benefits of Using a Titanium Centrifuge for Oil Processing

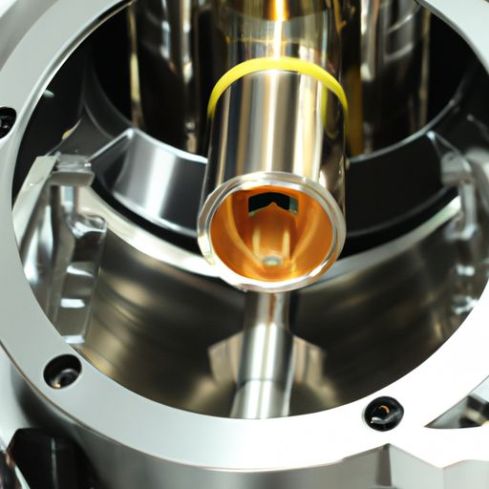

Titanium centrifuges have become increasingly popular in the oil processing industry due to their durability, efficiency, and ability to produce high-quality products. These centrifuges are designed to separate liquids and solids by spinning them at high speeds, allowing for the extraction of oil from various sources such as fruits, vegetables, and seeds. One of the main benefits of using a titanium centrifuge for oil processing is its ability to maintain the integrity of the oil while removing impurities and contaminants.

The use of a titanium centrifuge ensures that the oil extracted is of the highest quality, free from any unwanted particles or residues. This is crucial in the food industry, where purity and cleanliness are paramount. The centrifuge’s high-speed spinning action effectively separates the oil from other components, resulting in a pure and clean final product. Additionally, the use of titanium in the construction of the centrifuge ensures that it is resistant to corrosion and can withstand the harsh conditions of oil processing.

Another benefit of using a titanium centrifuge for oil processing is its efficiency in extracting oil from various sources. Whether it is extracting juice from fruits or separating oil from seeds, the centrifuge can handle a wide range of materials with ease. This versatility makes it a valuable tool for businesses in the Food And Beverage industry, as it allows for the extraction of oil from different sources without the need for multiple machines.

Furthermore, titanium centrifuges are known for their low maintenance requirements and long lifespan. The durable nature of titanium ensures that the centrifuge can withstand the rigors of daily use without deteriorating or breaking Down. This not only saves businesses money on repairs and replacements but also ensures that production can continue uninterrupted.

In addition to their durability and efficiency, titanium centrifuges are also environmentally friendly. The use of a centrifuge in oil processing reduces the need for chemical solvents and other harmful substances, making it a more sustainable option for businesses looking to minimize their environmental impact. By using a centrifuge, businesses can extract oil in a clean and efficient manner without compromising on quality or Safety.

Furthermore, titanium centrifuges are often equipped with advanced features such as automatic controls and Monitoring Systems, which allow for precise control over the extraction process. This ensures that the oil is extracted at the optimal speed and temperature, resulting in a higher yield and better quality product. Additionally, many titanium centrifuges come with a CE certificate, ensuring that they meet the highest safety and quality standards.

Overall, the benefits of using a titanium centrifuge for oil processing are numerous. From its durability and efficiency to its environmental friendliness and advanced features, the centrifuge is a valuable tool for businesses in the food and beverage industry. By investing in a titanium centrifuge, businesses can ensure that they are producing high-quality oil products while minimizing their environmental impact and maximizing their efficiency.