Table of Contents

The Process of Designing and Producing Custom Knit Sweaters for Small Businesses

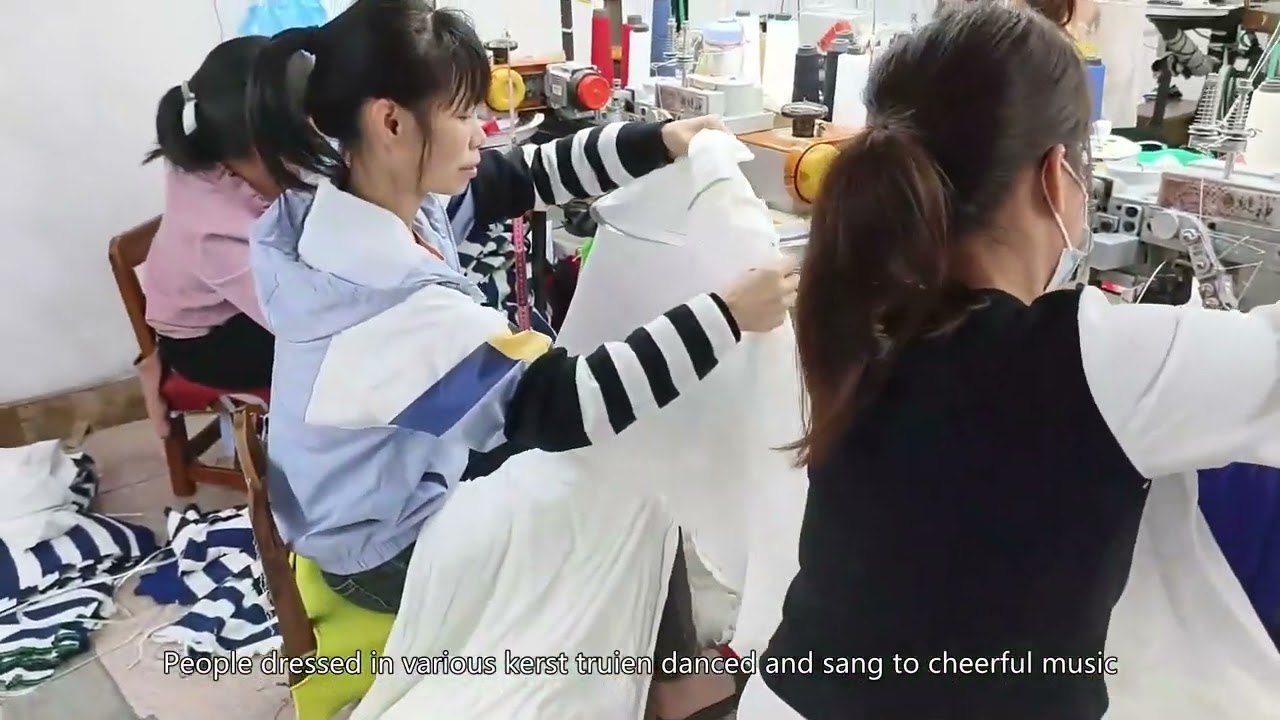

Manufacturing knit sweaters for small businesses involves a meticulous process that requires attention to detail and a keen eye for design. From the initial concept to the final product, every step in the production of custom knit sweaters is crucial to ensuring a high-quality finished product that meets the needs and expectations of the client.

Manufacturing knit sweaters for small businesses involves a meticulous process that requires attention to detail and a keen eye for design. From the initial concept to the final product, every step in the production of custom knit sweaters is crucial to ensuring a high-quality finished product that meets the needs and expectations of the client.

The process begins with the design phase, where the client works closely with the manufacturer to create a unique and personalized sweater that reflects their brand and style. This stage involves selecting the type of Yarn, color palette, and design elements that will be incorporated into the sweater. The manufacturer may also provide input on the feasibility of certain design choices and offer suggestions for improving the overall aesthetic of the garment.

| hombres sueter Producer | cardigan new Producer |

| bunny sweater Maker | back out sweater Maker |

| mens zipper pullover manufacturer | mountain sweater Maker |

Once the design has been finalized, the next step is to create a sample sweater for the client to review and approve. This sample serves as a prototype for the final product and allows the client to make any necessary adjustments or modifications before production begins. The manufacturer will work closely with the client to ensure that the sample meets their expectations and adheres to the agreed-upon design specifications.

After the sample has been approved, the manufacturing process can begin. This typically involves sourcing the necessary materials, such as yarn and Trimmings, and preparing the Production Line for the creation of the sweaters. The manufacturer will carefully follow the design specifications provided by the client to ensure that each sweater is made to their exact requirements.

The actual production of the sweaters involves a series of steps, including knitting the Fabric, cutting and sewing the pieces together, and adding any embellishments or finishing touches. Each sweater is carefully inspected at various stages of the production process to ensure that it meets the quality standards set by the client and the manufacturer.

Once the sweaters have been completed, they are typically packaged and shipped to the client for distribution. The manufacturer may also offer additional services, such as labeling or branding, to further customize the sweaters and enhance their appeal to consumers.

| sweater production factory | ugly sweater maker |

| woolen sweater factory | chinese sweaters |

| sweater Manufacturer | chinese cashmere sweaters |

| sweater Producer | ugly sweaters china |

Overall, the process of designing and producing custom knit sweaters for small businesses requires a combination of creativity, technical skill, and attention to detail. By working closely with the client and following a systematic approach to production, manufacturers can create high-quality sweaters that meet the unique needs and preferences of their clients.

| pilot sweater Producer | knitwear cashmere Producer |

| boxy knitted sweater Producer | youth fleece sweater Maker |

| knitwear polo Maker | preparatory sweater Maker |

| custom hair sweater Maker | recycled sweater manufacturer |

| crochet sueter manufacturer | sweater cable Maker |

| utility sweater set manufacturer | sweaters manufacturer |

| christmas sweater kids Producer | maglione ragazza manufacturer |

| woven knit sweaters Producer | sueter verde Producer |

In conclusion, manufacturing knit sweaters for small businesses is a complex and intricate process that requires careful planning and execution. By following a systematic approach to design and production, manufacturers can create custom sweaters that meet the needs and expectations of their clients while also showcasing their creativity and craftsmanship. With attention to detail and a commitment to quality, manufacturers can produce knit sweaters that are not only stylish and fashionable but also durable and long-lasting.

Sustainable Practices in Manufacturing Knit Sweaters: How to Reduce Waste and Carbon Footprint

Manufacturing knit sweaters is a complex process that involves various stages, from sourcing raw materials to the final product. In recent years, there has been a growing emphasis on sustainable practices in the fashion industry, including the manufacturing of knitwear. By implementing eco-friendly techniques and reducing waste, manufacturers can significantly reduce their carbon footprint and contribute to a more sustainable future.

One of the key ways to reduce waste in the manufacturing of knit sweaters is by carefully sourcing materials. Sustainable materials such as organic cotton, bamboo, and recycled fibers are becoming increasingly popular in the fashion industry. These materials are not only better for the Environment but also for the workers who produce them. By choosing sustainable materials, manufacturers can reduce the amount of waste generated during the manufacturing process and minimize their impact on the environment.

| over sweater Production\u00a0 | turtleneck sweater men Processing plant |

| short cardigan Factory complex | Camouflage sweaters factory |

| turtleneck sweater Processing plant | cardigan sweater baby factory |

| tapestry cardigan Processing plant | sweater manufacturers Processing factory |

| sweater woman Manufacturing plant | \u00a0baby knitted sweater Firm |

| knitted pullover Processing plant | \u00a0men christmas sweater Bespoke |

| summer thin cardigan Manufacturing plant | zip fleece pullover odm |

Another important aspect of sustainable manufacturing is the use of eco-friendly dyes and Chemicals. Traditional dyes and chemicals used in the textile industry can be harmful to the environment and to the workers who handle them. By switching to eco-friendly alternatives, manufacturers can reduce their carbon footprint and create a safer working environment for their employees. Additionally, using natural dyes and chemicals can help to reduce water pollution and minimize the impact on local ecosystems.

| Spring clothing | Summer clothing | Autumn clothes | Winter clothing | Autumn sweater | Winter sweater |

| Long-sleeved all-purpose sweater | Short-sleeved thin knit | Long-sleeved thin knitwear | Long sleeve thick knitwear | Long-sleeved thick knit | Long sleeved long thick knit |

| mohair sweater Maker | clothing manufacturers Maker | wool top Producer | sweaters zip Maker | \u00a0sweater Dresses Producer |

| sueter nio Maker | fleece knit sweater Producer | sweater women dress manufacturer | knitwear sweater manufacturer | heren pullover Manufacturing enterprise |

In addition to sourcing sustainable materials and using eco-friendly dyes, manufacturers can also reduce waste by optimizing their production processes. By implementing lean manufacturing techniques, manufacturers can streamline their operations and minimize waste at every stage of the production process. This includes reducing the amount of fabric waste generated during cutting and sewing, as well as finding innovative ways to reuse or recycle leftover materials.

One way to reduce waste in the manufacturing of knit sweaters is by implementing a zero-waste production model. This involves designing garments in such a way that no fabric is wasted during the cutting and sewing process. By carefully planning the layout of each pattern piece and using innovative cutting techniques, manufacturers can minimize fabric waste and create more sustainable products. Additionally, by reusing or Recycling leftover materials, manufacturers can further reduce their environmental impact and create a more circular economy.

| vest cardigan manufacturer | oversized sweaters Maker | size cardigan Producer |

| thin knitted dress Producer | branded sweater Producer | knitted hoodie sweater Maker |

| alpaca knitwear Producer | luxury sweaters for men manufacturer | knitted vest custom Producer |

| mens cardigan makers | personalized christmas jumpers |

| cardigan Producer | jumper custom |

| cardigans Factory | jumper factory |

| knit dress china | knitwear custom |

| knit makers | knitwear Customizability |

| knit Production factory | knitwear Customizability |

In conclusion, sustainable practices in the manufacturing of knit sweaters are essential for reducing waste and minimizing the industry’s carbon footprint. By carefully sourcing sustainable materials, using eco-friendly dyes and chemicals, and optimizing production processes, manufacturers can create more environmentally friendly products and contribute to a more sustainable future. Implementing a zero-waste production model and finding innovative ways to reuse or recycle leftover materials can further reduce waste and create a more circular economy. By prioritizing sustainability in the manufacturing of knit sweaters, manufacturers can help to protect the environment and create a more ethical and responsible fashion industry.

| knitwearampang Maker | mens rhinestone sweater Maker |

| zip sweater Producer | triko kazak manufacturer |

| Down sweater Producer | fashion manufacturers Producer |

| wool sweater for girls manufacturer | men zipper sweater Producer |