Table of Contents

Benefits of Using Servo Motor Press Equipment for Precision Manufacturing

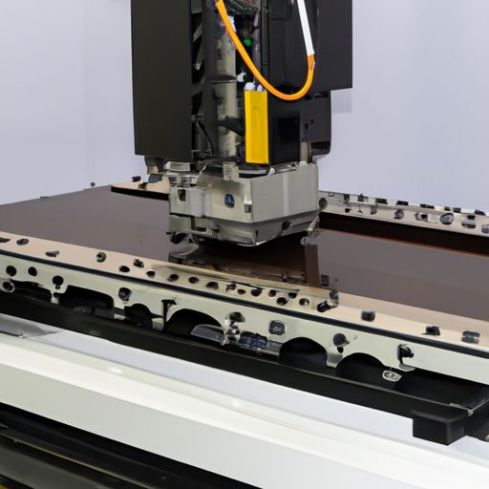

In the world of precision manufacturing, the use of servo motor press equipment has become increasingly popular due to its high control accuracy and efficiency. One such example is the HONTEC FDA-350E Flat-bed die cutting machine, which utilizes servo motor technology for both drive and tension control. This article will explore the benefits of using servo motor press equipment in precision manufacturing processes, focusing on the control accuracy and efficiency that it offers.

Servo Motors are known for their ability to provide precise control over speed, position, and torque, making them ideal for applications that require high Levels of accuracy. In the case of the HONTEC FDA-350E Flat-bed die cutting machine, the servo motor drive system ensures that the cutting process is carried out with the utmost precision. This is essential in industries such as packaging, automotive, and electronics, where even the smallest deviation in cutting dimensions can Lead to product defects.

Furthermore, servo motor press equipment offers superior tension control, which is crucial in applications where materials need to be fed through the machine at a consistent rate. The HONTEC FDA-350E Flat-bed die cutting machine utilizes servo motors to maintain precise tension levels throughout the cutting process, ensuring that the material is fed through the machine smoothly and accurately. This not only improves the quality of the finished product but also reduces waste and downtime caused by material jams or misfeeds.

Another key benefit of using servo motor press equipment is its high control accuracy. Servo motors are capable of making rapid adjustments to speed and position, allowing for precise control over the cutting process. This level of accuracy is essential in applications where tight tolerances are required, such as in the production of electronic components or medical devices. The HONTEC FDA-350E Flat-bed die cutting machine leverages servo motor technology to ensure that each cut is made with the highest level of precision, resulting in consistent and reliable results.

Another key benefit of using servo motor press equipment is its high control accuracy. Servo motors are capable of making rapid adjustments to speed and position, allowing for precise control over the cutting process. This level of accuracy is essential in applications where tight tolerances are required, such as in the production of electronic components or medical devices. The HONTEC FDA-350E Flat-bed die cutting machine leverages servo motor technology to ensure that each cut is made with the highest level of precision, resulting in consistent and reliable results.

In addition to control accuracy, servo motor press equipment also offers improved energy efficiency compared to traditional hydraulic or pneumatic systems. Servo motors only consume power when they are in operation, unlike hydraulic systems that require constant energy to maintain pressure. This not only reduces energy costs but also contributes to a more sustainable manufacturing process. The HONTEC FDA-350E Flat-bed die cutting machine is designed with energy efficiency in mind, utilizing servo motors to minimize power consumption while maximizing performance.

Overall, the use of servo motor press equipment, such as the HONTEC FDA-350E Flat-bed die cutting machine, offers a range of benefits for precision manufacturing processes. From high control accuracy and tension control to improved energy efficiency, servo motors provide a reliable and efficient solution for industries that require precise and consistent results. By investing in servo motor technology, manufacturers can enhance the quality of their products, reduce waste, and improve overall productivity.

Achieving High Control Accuracy in Tension Control with Hontec FDA-350E Flat-Bed Die Cutting Machine

In the world of die cutting, precision and accuracy are essential for producing high-quality products. One key factor in achieving this level of precision is the control of tension during the cutting process. Tension control ensures that the material being cut is held taut and stable, preventing any distortion or misalignment that could affect the final product. Hontec’s FDA-350E Flat-Bed Die Cutting Machine is equipped with servo motor press equipment drive and tension control, offering unparalleled control accuracy for a wide range of die cutting applications.

Servo motors are known for their high precision and accuracy, making them ideal for applications where tight control is required. In the FDA-350E, servo motors drive the press equipment, providing smooth and consistent motion during the cutting process. This precise control allows for accurate cutting of even the most intricate designs, ensuring that each piece is cut to the exact specifications required.

But servo motor drive is just one part of the equation when it comes to achieving high control accuracy in tension control. The FDA-350E also features advanced tension control systems that work in conjunction with the servo motors to maintain optimal tension throughout the cutting process. This ensures that the material being cut remains stable and flat, preventing any stretching or distortion that could affect the final product.

One of the key features of the tension control system in the FDA-350E is its ability to adjust tension on the fly. This means that the machine can automatically compensate for changes in material thickness or elasticity, ensuring that the tension remains consistent throughout the cutting process. This level of control accuracy is essential for producing high-quality products with tight tolerances, such as labels, Stickers, and packaging materials.

In addition to its precise tension control, the FDA-350E also offers a range of other features that make it an ideal choice for a wide range of die cutting applications. Its flat-bed design allows for easy loading and unloading of materials, while its compact footprint makes it suitable for use in a variety of production environments. The machine is also equipped with a user-friendly interface that allows operators to easily program cutting parameters and monitor the cutting process in real-time.

Overall, the Hontec FDA-350E Flat-Bed Die Cutting Machine offers unmatched control accuracy in tension control, thanks to its servo motor press equipment drive and advanced tension control systems. Whether you are cutting paper, cardboard, plastic, or other materials, this machine provides the precision and consistency you need to produce high-quality products every time. With its combination of advanced technology and user-friendly design, the FDA-350E is a versatile and reliable solution for all your die cutting needs.