Table of Contents

Quality Control Measures in Jersey Pullover Manufacturing Plants

Quality control measures are essential in the manufacturing of jersey pullovers to ensure that the final product meets the highest standards of quality. These measures are put in place to identify and rectify any defects or issues that may arise during the production process. By implementing strict quality control measures, manufacturers can guarantee that their jersey pullovers are of the highest quality and meet customer expectations.

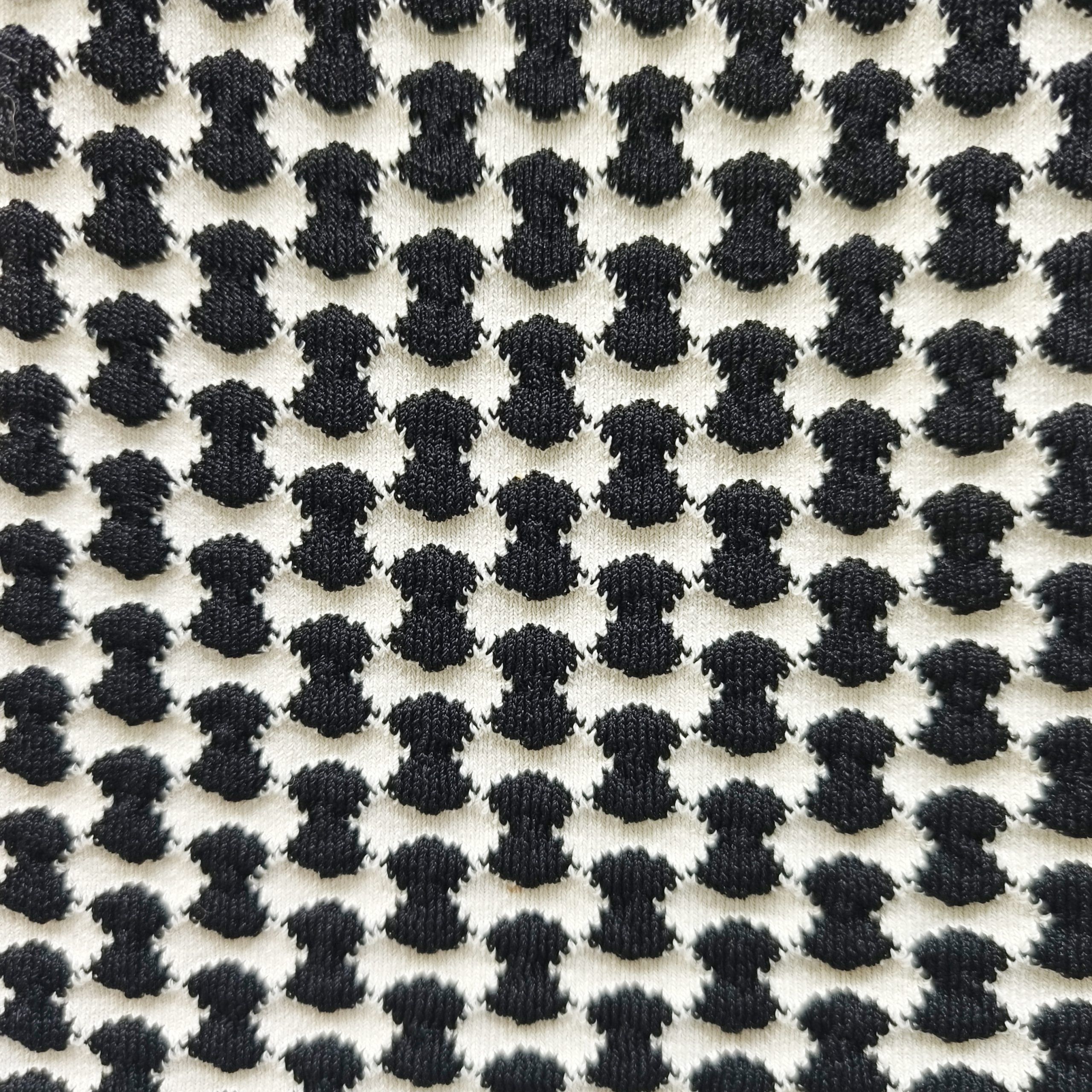

One of the key quality control measures in jersey pullover manufacturing plants is the inspection of raw materials. Before production begins, all materials such as Fabric, Thread, and Trimmings are thoroughly inspected to ensure that they meet the required specifications. Any materials that do not meet the standards are rejected and replaced with high-quality alternatives. This initial inspection is crucial in ensuring that the final product is of the highest quality.

Once production begins, quality control measures are implemented at every stage of the manufacturing process. Each step, from cutting the fabric to sewing the pieces together, is closely monitored to ensure that the pullovers are being made according to the specified design and size. Any deviations from the standard are immediately addressed to prevent further issues Down the line.

In addition to monitoring the production process, manufacturers also conduct regular quality checks on the finished pullovers. This involves inspecting the seams, stitching, and overall appearance of the garment to ensure that it meets the required quality standards. Any defects or imperfections are identified and corrected before the pullovers are packaged and shipped to customers.

To further ensure the quality of jersey pullovers, manufacturers also conduct random quality audits throughout the production process. These audits involve inspecting a sample of finished pullovers to check for any defects or issues that may have been missed during the initial inspection. By conducting these audits, manufacturers can identify any potential problems and take corrective action to prevent them from occurring in future batches.

Another important quality control measure in jersey pullover manufacturing plants is the implementation of strict hygiene and cleanliness standards. Cleanliness is crucial in preventing contamination and ensuring that the pullovers are free from any dirt or debris that may affect their quality. Manufacturers adhere to strict cleanliness protocols to maintain a clean and hygienic production Environment.

In conclusion, quality control measures play a vital role in ensuring that jersey pullovers are manufactured to the highest standards of quality. By implementing strict quality checks at every stage of the production process, manufacturers can guarantee that their pullovers meet customer expectations and adhere to industry standards. From inspecting raw materials to conducting random quality audits, these measures are essential in producing high-quality jersey pullovers that are durable, comfortable, and stylish.

Sustainable Practices in Jersey Pullover Manufacturing Plants

Sustainable Practices in Jersey Pullover Manufacturing Plants

In recent years, there has been a growing awareness of the environmental impact of the fashion industry. From the use of harmful Chemicals in production to the massive amounts of waste generated, the industry has come under scrutiny for its unsustainable practices. However, there are manufacturers who are taking steps to reduce their environmental footprint and adopt more sustainable practices. One such area where sustainable practices are being implemented is in jersey pullover manufacturing plants.

One of the key ways in which jersey pullover manufacturing plants are becoming more sustainable is through the use of eco-friendly materials. Traditionally, jersey pullovers were made from synthetic fibers such as polyester, which are derived from non-renewable resources and are not biodegradable. However, many manufacturers are now using organic cotton, bamboo, and other sustainable materials in their production process. These materials are not only better for the environment, but they also tend to be softer and more breathable, making them a popular choice among consumers.

Another important aspect of sustainable jersey pullover manufacturing is the reduction of water usage. The textile industry is known for its high water consumption, with millions of gallons of water being used in the production of clothing each year. Manufacturers are now implementing water-saving technologies such as closed-loop systems and water Recycling to minimize their water usage. By reusing and recycling water, manufacturers can significantly reduce their environmental impact and conserve this precious resource.

| sleeve crop Producer | basic Sweaters Maker |

| girls knit dress Maker | anak lakilaki sweater manufacturer |

| varsity sweaters Maker | fleece junior sweater Producer |

| green cardigan Producer | knitwear murah Maker |

| cotton pullover sweater Producer | knitted sweater crop Producer |

| custom Baby Sweaters Maker | maglione uomo manufacturer |

In addition to reducing water usage, jersey pullover manufacturing plants are also focusing on reducing energy consumption. Many manufacturers are investing in energy-efficient machinery and equipment, as well as implementing energy-saving practices such as using natural light and optimizing production schedules to minimize energy waste. By reducing their energy consumption, manufacturers not only lower their carbon footprint but also save on operating costs, making it a win-win situation for both the environment and the bottom line.

Waste reduction is another key area where jersey pullover manufacturing plants are making strides towards sustainability. Traditionally, the textile industry has been notorious for its high Levels of waste, with tons of fabric scraps and offcuts ending up in landfills each year. However, manufacturers are now implementing waste reduction strategies such as fabric recycling, upcycling, and composting to minimize their waste output. By finding creative ways to reuse and repurpose materials, manufacturers can reduce their environmental impact and create a more circular economy.

Overall, sustainable practices in jersey pullover manufacturing plants are becoming increasingly important as consumers demand more eco-friendly and ethical products. By using eco-friendly materials, reducing water and energy consumption, and minimizing waste, manufacturers can not only reduce their environmental footprint but also appeal to a growing market of environmentally conscious consumers. As the fashion industry continues to evolve, it is crucial for manufacturers to prioritize sustainability in their production processes to ensure a more sustainable future for the industry and the planet.