Table of Contents

Benefits of Using Jackhammer Air Drill Demolition in Construction Projects

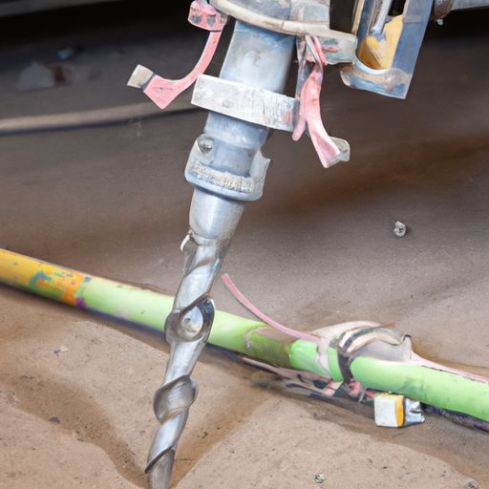

Construction projects often require the use of heavy-duty equipment to get the job done efficiently and effectively. One such piece of equipment that is commonly used in construction projects is the jackhammer air drill demolition. This powerful tool is essential for breaking through tough materials like concrete, rock, and asphalt. In this article, we will explore the benefits of using a jackhammer air drill demolition in construction projects.

One of the main advantages of using a jackhammer air drill demolition is its efficiency. This tool is designed to deliver high-impact blows to the surface it is being used on, making it easier to break through tough materials quickly. This can save construction workers valuable time and energy, allowing them to complete their tasks more efficiently.

Another benefit of using a jackhammer air drill demolition is its versatility. This tool can be used for a wide range of applications, from breaking up concrete to digging trenches. Its ability to handle various tasks makes it a valuable asset on any construction site.

In addition to its efficiency and versatility, a jackhammer air drill demolition is also known for its durability. These tools are built to withstand the rigors of construction work, making them a reliable option for tough jobs. This durability ensures that the tool will last for years to come, providing a long-term solution for construction projects.

Furthermore, using a jackhammer air drill demolition can also improve Safety on a construction site. By using this tool, construction workers can avoid the need for manual labor, reducing the risk of injury. Additionally, the controlled nature of the jackhammer air drill demolition allows for precise and accurate work, minimizing the risk of accidents.

One of the key benefits of using a jackhammer air drill demolition in construction projects is its cost-effectiveness. While these tools may require an initial investment, their efficiency and durability make them a cost-effective option in the long run. By using a jackhammer air drill demolition, construction companies can save money on labor costs and complete projects more quickly, ultimately increasing their bottom line.

Overall, the benefits of using a jackhammer air drill demolition in construction projects are clear. From its efficiency and versatility to its durability and cost-effectiveness, this tool is a valuable asset on any construction site. By incorporating a jackhammer air drill demolition into their projects, construction companies can improve productivity, enhance safety, and save money in the long run.

Comparison of HBH16, HBH19, DTH, HBH14 Back Rock Drill for Mine Tunnel Microtunnel Factory Supply TY24C Pneumatic Drill

Jackhammers and air drills are essential tools in the construction and mining industries. They are used for various tasks such as demolition, drilling, and tunneling. In this article, we will compare four popular models of air drills: HBH16, HBH19, DTH, HBH14 Back Rock Drill, and TY24C Pneumatic Drill.

The HBH16 is a powerful jackhammer air drill that is commonly used for demolition work. It is known for its high impact energy and efficiency in breaking through tough materials. The HBH19, on the other hand, is a versatile air drill that can be used for both drilling and demolition tasks. It is lightweight and easy to handle, making it a popular choice among construction workers.

The DTH air drill is a specialized tool that is used for drilling in hard rock formations. It is equipped with a Down-the-hole Hammer that delivers high impact energy to break through solid rock. The HBH14 Back Rock Drill is another powerful tool that is commonly used in mining tunnels. It is designed to withstand harsh working conditions and is known for its durability and reliability.

Lastly, the TY24C Pneumatic Drill is a compact and lightweight tool that is ideal for drilling in tight spaces. It is commonly used in microtunneling projects where precision drilling is required. Despite its small size, the TY24C is capable of delivering high impact energy and is suitable for a wide range of drilling tasks.

When comparing these four air drills, it is important to consider factors such as power, efficiency, durability, and versatility. The HBH16 and HBH19 are both powerful tools that are suitable for heavy-duty demolition work. They are known for their high impact energy and efficiency in breaking through tough materials. The DTH air drill, on the other hand, is a specialized tool that is designed for drilling in hard rock formations. It is equipped with a down-the-hole hammer that delivers high impact energy to break through solid rock.

The HBH14 Back Rock Drill is a durable and reliable tool that is commonly used in mining tunnels. It is designed to withstand harsh working conditions and is known for its longevity. The TY24C Pneumatic Drill, on the other hand, is a compact and lightweight tool that is ideal for drilling in tight spaces. It is commonly used in microtunneling projects where precision drilling is required.

In conclusion, each of these air drills has its own unique features and advantages. The HBH16 and HBH19 are powerful tools that are suitable for heavy-duty demolition work, while the DTH air drill is designed for drilling in hard rock formations. The HBH14 Back Rock Drill is a durable and reliable tool that is commonly used in mining tunnels, and the TY24C Pneumatic Drill is a compact and lightweight tool that is ideal for drilling in tight spaces. Ultimately, the choice of air drill will depend on the specific needs of the project and the type of work that needs to be done.