Table of Contents

Benefits of Using a Full Automatic CNC High Speed Insulating Glass Process Line Polish Machine

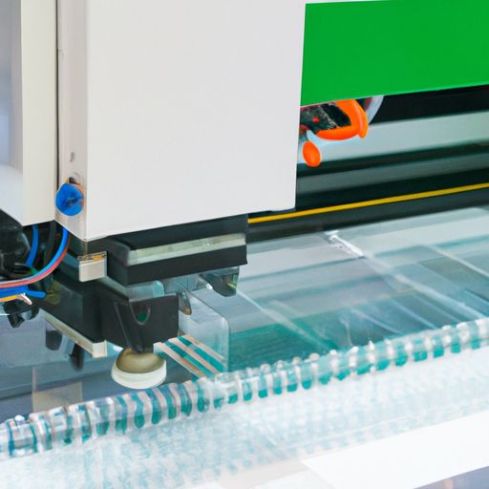

Insulating glass is a popular choice for windows and doors in modern buildings due to its energy efficiency and sound insulation properties. To ensure the quality and durability of insulating glass units, it is essential to use a high-speed process line polish machine. These machines are designed to automate the polishing process, resulting in a more efficient and consistent finish.

One of the key benefits of using a full automatic CNC high-speed insulating glass process line polish machine is the speed at which it operates. These machines are capable of polishing glass at a much faster rate than manual methods, saving time and increasing productivity. This is especially important for manufacturers who need to produce large quantities of insulating glass units quickly and efficiently.

In addition to speed, full automatic CNC high-speed polish machines also offer a high level of precision and accuracy. The CNC technology allows for precise control over the polishing process, ensuring that each glass panel is polished to the exact specifications required. This results in a consistent finish across all units, reducing the risk of defects and ensuring a high-quality end product.

Another benefit of using a full automatic CNC high-speed polish machine is the reduction in labor costs. By automating the polishing process, manufacturers can reduce the need for manual labor, saving time and money. This also reduces the risk of human error, resulting in a more consistent and reliable finish.

Furthermore, full automatic CNC high-speed polish machines are designed to be user-friendly and easy to operate. With intuitive controls and automated processes, operators can quickly learn how to use the machine and produce high-quality insulating glass units with minimal training. This makes it easier for manufacturers to scale up production and meet increasing demand for their products.

In addition to these benefits, full automatic CNC high-speed polish machines also offer a range of features that enhance the overall efficiency of the insulating glass production process. These machines are equipped with advanced Sensors and Monitoring Systems that can detect and correct any issues that may arise during the polishing process. This helps to minimize downtime and ensure that production runs smoothly.

Overall, the use of a full automatic CNC high-speed insulating glass process line polish machine offers a range of benefits for manufacturers. From increased speed and precision to reduced labor costs and enhanced efficiency, these machines are an essential tool for producing high-quality insulating glass units. By investing in this technology, manufacturers can improve their production processes and deliver superior products to their customers.

How to Maximize Efficiency and Quality in Insulating Glass Production with a Full Automatic CNC High Speed Process Line

Insulating glass production is a complex process that requires precision and efficiency to ensure high-quality end products. One key component of this process is the use of a polish machine in the Production Line. The Full Automatic CNC High Speed polish machine is a cutting-edge technology that can greatly enhance the efficiency and quality of insulating glass production.

The Full Automatic CNC High Speed polish machine is designed to streamline the polishing process, reducing the need for manual labor and increasing production speed. This machine is equipped with advanced CNC technology, allowing for precise control over the polishing process. With its high-speed capabilities, the Full Automatic CNC High Speed polish machine can significantly reduce production time, allowing for faster turnaround and increased output.

One of the key benefits of the Full Automatic CNC High Speed polish machine is its ability to consistently produce high-quality results. The machine is programmed to follow precise polishing parameters, ensuring that each piece of glass is polished to perfection. This level of consistency is essential in insulating glass production, as even minor imperfections can compromise the integrity of the final product.

In addition to its efficiency and quality benefits, the Full Automatic CNC High Speed polish machine also offers a number of features that make it easy to use and maintain. The machine is equipped with a user-friendly interface that allows operators to easily program and monitor the polishing process. This intuitive interface helps to minimize the risk of errors and ensures that the machine operates smoothly and efficiently.

Furthermore, the Full Automatic CNC High Speed polish machine is designed with durability in mind. The machine is built to withstand the rigors of continuous use in a production Environment, ensuring that it will provide reliable performance for years to come. This durability helps to minimize downtime and maintenance costs, further enhancing the overall efficiency of the insulating glass production process.

To maximize the efficiency and quality of insulating glass production with a Full Automatic CNC High Speed polish machine, it is important to follow best practices for operation and maintenance. Regularly cleaning and maintaining the machine can help to prevent issues and ensure optimal performance. Additionally, providing proper training for operators can help to maximize the machine’s capabilities and minimize the risk of errors.

In conclusion, the Full Automatic CNC High Speed polish machine is a valuable tool for insulating glass production, offering a range of benefits that can help to enhance efficiency and quality. By investing in this cutting-edge technology and following best practices for operation and maintenance, manufacturers can optimize their production processes and achieve superior results. With its advanced features and user-friendly design, the Full Automatic CNC High Speed polish machine is a smart choice for companies looking to stay ahead in the competitive insulating glass industry.