Table of Contents

Benefits of Using API 5CT Oil Seamless Tubing Coupling in Oilfield Operations

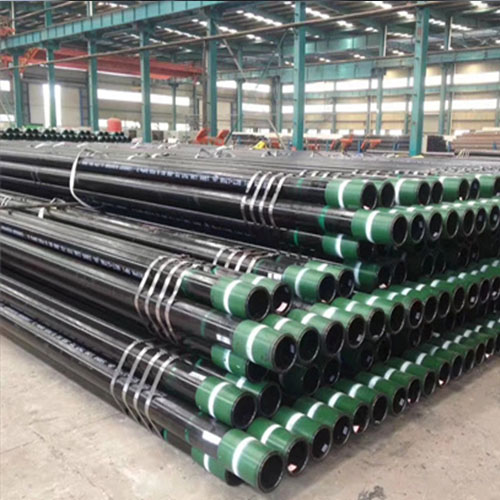

API 5CT oil seamless tubing coupling and casing coupling are essential components in oilfield operations. These couplings are designed to connect two pieces of tubing or casing together, creating a secure and leak-proof seal. The API 5CT standard ensures that these couplings meet strict quality and performance requirements, making them ideal for use in the demanding conditions of the oilfield.

One of the key benefits of using API 5CT oil seamless tubing coupling is its durability. These couplings are made from high-quality materials that are able to withstand the harsh conditions of the oilfield, including high pressure, extreme temperatures, and corrosive substances. This durability ensures that the couplings will not fail prematurely, reducing the risk of costly downtime and repairs.

In addition to their durability, API 5CT oil seamless tubing couplings are also designed for easy installation and removal. This makes them ideal for use in situations where quick and efficient maintenance is required, such as during well interventions or workovers. The seamless design of these couplings also helps to minimize the risk of leaks, ensuring that the oilfield operation remains safe and efficient.

Another benefit of using API 5CT oil seamless tubing coupling is their compatibility with a wide range of tubing and casing sizes. This versatility allows operators to use the same couplings for multiple applications, reducing the need for multiple types of couplings and simplifying inventory management. This compatibility also ensures that the couplings can be easily integrated into existing oilfield infrastructure, minimizing the need for costly modifications or upgrades.

Furthermore, API 5CT oil seamless tubing couplings are designed to provide a tight and secure seal, preventing leaks and ensuring that the oilfield operation remains efficient and productive. This tight seal also helps to prevent the ingress of contaminants into the wellbore, reducing the risk of equipment damage and environmental harm. By using API 5CT oil seamless tubing couplings, operators can ensure that their oilfield operation remains safe, reliable, and environmentally responsible.

In conclusion, API 5CT oil seamless tubing couplings offer a range of benefits for oilfield operations. Their durability, ease of installation, compatibility, and tight seal make them an ideal choice for connecting tubing and casing in the demanding conditions of the oilfield. By using API 5CT oil seamless tubing couplings, operators can reduce the risk of downtime, improve efficiency, and ensure the Safety and integrity of their oilfield operation.

Importance of Properly Selecting and Installing Casing Couplings for API 5CT Oilfield Applications

API 5CT oil seamless tubing coupling and casing coupling play a crucial role in the oilfield industry. These components are essential for connecting sections of tubing and casing in oil wells, ensuring the integrity and efficiency of the wellbore. Properly selecting and installing casing couplings is of utmost importance to ensure the safety and productivity of oilfield operations.

When it comes to selecting casing couplings for API 5CT oilfield applications, there are several factors that need to be taken into consideration. The first and foremost consideration is the material of the coupling. Casing couplings are typically made of high-strength steel to withstand the extreme conditions of the oilfield Environment. It is important to choose couplings that are manufactured to API 5CT specifications to ensure compatibility with other components in the wellbore.

Another important factor to consider when selecting casing couplings is the size and Thread type. Casing couplings come in various sizes and thread types to accommodate different casing sizes and connections. It is essential to choose couplings that are compatible with the casing being used in the wellbore to ensure a proper fit and seal.

In addition to material, size, and thread type, the design of the casing coupling is also an important consideration. Casing couplings are designed to provide a secure and leak-proof connection between casing joints. It is crucial to select couplings that have a robust design and are manufactured to high-quality standards to ensure the integrity of the wellbore.

Once the appropriate casing couplings have been selected, proper installation is key to ensuring the effectiveness of the coupling in the wellbore. Casing couplings should be installed according to the manufacturer’s specifications and industry best practices. Improper installation can Lead to leaks, casing failures, and other costly issues that can impact the safety and productivity of oilfield operations.

Proper installation of casing couplings involves ensuring that the coupling is properly aligned with the casing joint, applying the correct amount of torque to achieve a secure connection, and inspecting the coupling for any defects or damage before installation. It is also important to use the appropriate tools and equipment for installation to prevent damage to the coupling or casing.

In conclusion, selecting and installing casing couplings for API 5CT oilfield applications is a critical aspect of oilfield operations. Properly selected and installed casing couplings ensure the integrity and efficiency of the wellbore, ultimately contributing to the safety and productivity of oilfield operations. By considering factors such as material, size, thread type, and design when selecting casing couplings, and following proper installation procedures, oilfield operators can ensure the reliability and performance of their wellbores.