Table of Contents

Benefits of Using an Acupuncture Needle Straightening Machine

Acupuncture has been used for centuries as a traditional Chinese Medicine practice to treat various ailments and promote overall health and well-being. The practice involves inserting thin needles into specific points on the body to stimulate energy flow and restore balance. With the growing popularity of acupuncture in Western medicine, the demand for high-quality acupuncture needles has also increased.

One of the key components of acupuncture treatment is the use of straight and sharp needles. However, due to the delicate nature of these needles, they can easily become bent or dull during handling and storage. This can not only affect the effectiveness of the treatment but also pose a risk of injury to the patient. To address this issue, many acupuncture practitioners are turning to acupuncture needle straightening machines.

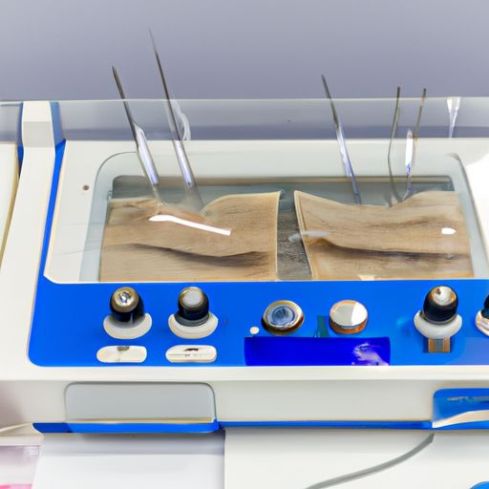

Acupuncture needle straightening machines are designed to straighten and cut acupuncture needles automatically, ensuring that each needle is in perfect condition for use. These machines use advanced technology to straighten bent needles and sharpen dull ones, resulting in needles that are straight, sharp, and ready for use. By using a needle straightening machine, acupuncture practitioners can save time and ensure the quality and consistency of their needles.

One of the key benefits of using an acupuncture needle straightening machine is the precision and accuracy it provides. These machines are designed to straighten needles with a high degree of accuracy, ensuring that each needle is perfectly straight and sharp. This level of precision is essential for ensuring the effectiveness of acupuncture treatment, as even a slight bend or dullness in a needle can affect its ability to stimulate the body’s energy flow.

Another benefit of using an acupuncture needle straightening machine is the time and labor savings it provides. Manual straightening and sharpening of acupuncture needles can be a time-consuming and labor-intensive process, especially for practitioners who use a large volume of needles. By using a needle straightening machine, practitioners can automate this process and save valuable time that can be better spent on patient care.

In addition to precision and time savings, acupuncture needle straightening machines also offer a cost-effective solution for practitioners. These machines are designed to be durable and long-lasting, providing a reliable solution for straightening and cutting needles over an extended period of time. By investing in a needle straightening machine, practitioners can reduce the need for frequent needle replacements and ensure that they always have a supply of high-quality needles on hand.

Overall, the benefits of using an acupuncture needle straightening machine are clear. These machines provide precision, time savings, and cost-effectiveness, making them an essential tool for any acupuncture practitioner looking to improve the quality and consistency of their needles. By investing in a needle straightening machine, practitioners can ensure that their needles are always in perfect condition, allowing them to provide the best possible care for their patients.

How to Choose the Right Automatic Acupuncture Needle Cutting Machine

Acupuncture has been used for centuries as a form of alternative medicine to treat various ailments and promote overall wellness. With the increasing popularity of acupuncture, the demand for high-quality acupuncture needles has also risen. As a result, many acupuncture clinics and manufacturers are turning to automatic acupuncture needle cutting machines to streamline their production process.

Choosing the right automatic acupuncture needle cutting machine is crucial for ensuring the efficiency and accuracy of your Production Line. There are several factors to consider when selecting a machine that meets your specific needs.

First and foremost, you should consider the size and type of needles that you will be cutting. Different machines are designed to handle different sizes and types of needles, so it is important to choose a machine that is compatible with the needles you will be using.

Additionally, you should consider the speed and efficiency of the machine. Look for a machine that can cut a large number of needles quickly and accurately to keep up with the demands of your production line. Some machines are equipped with advanced technology that allows for precise cutting and straightening of needles, which can help improve the quality of your products.

Another important factor to consider is the ease of use and maintenance of the machine. Look for a machine that is user-friendly and easy to operate, with clear instructions and minimal maintenance requirements. This will help reduce downtime and ensure that your production line runs smoothly.

It is also important to consider the cost of the machine and your budget. Automatic acupuncture needle cutting machines can vary widely in price, so it is important to choose a machine that fits within your budget while still meeting your production needs.

When researching different machines, be sure to read reviews and testimonials from other users to get an idea of the machine’s performance and reliability. You may also want to reach out to manufacturers directly to ask any questions you may have about the machine and its capabilities.

In conclusion, choosing the right automatic acupuncture needle cutting machine is essential for ensuring the efficiency and accuracy of your production line. Consider factors such as needle size, speed, ease of use, maintenance, and cost when selecting a machine that meets your specific needs. By taking the time to research and compare different machines, you can find the perfect machine to help streamline your production process and improve the quality of your acupuncture needles.