Table of Contents

Sure! Here are two blog topics related to Leicester knitwear manufacturers and knitting machine sweater manufacturing companies:

Leicester Knitwear Manufacturers: Enhancing the Art of Sweater Manufacturing

In the realm of fashion, knitwear holds a special place. The intricacy and Beauty of knitted garments captivate the senses, making them a timeless addition to any wardrobe. Leicester, a city renowned for its textile heritage, boasts a rich history of knitwear manufacturing. In this article, we will explore the world of Leicester knitwear manufacturers and the art of sweater manufacturing using Knitting Machines.

Leicester, a city nestled in the heart of England, has long been recognized as a hub for textile production. The city’s knitwear manufacturers have played a pivotal role in shaping the fashion industry, combining traditional craftsmanship with modern techniques to create exquisite knitted garments. These manufacturers have honed their skills over generations, passing Down invaluable knowledge and expertise.

The process of sweater manufacturing begins with the design phase. Knitwear manufacturers collaborate with designers to bring their creative visions to life. They meticulously select the finest yarns, considering factors such as texture, color, and composition. Leicester knitwear manufacturers take pride in their commitment to using high-quality materials, ensuring that every sweater is a testament to both style and durability.

Once the design and materials are finalized, knitting machines come into play. These machines are marvels of engineering, capable of intricately weaving yarns together to form the desired patterns and textures. Leicester knitwear manufacturers have embraced the technological advancements in knitting machines, incorporating them into their production processes to enhance efficiency and precision.

In a world driven by fast fashion, Leicester knitwear manufacturers stand out for their dedication to craftsmanship. Each sweater is carefully crafted, with skilled artisans overseeing every step of the manufacturing process. Attention to detail is paramount, ensuring that every stitch is perfect and every seam flawlessly finished.

The art of sweater manufacturing is a delicate balance between tradition and innovation. Leicester knitwear manufacturers have mastered this balance, blending age-old techniques with modern technology. They understand that while knitting machines offer speed and consistency, the human touch is irreplaceable. Skilled artisans breathe life into each garment, infusing it with character and charm.

Collaboration is at the core of Leicester’s knitwear manufacturing industry. Manufacturers work closely with designers, retailers, and other stakeholders to create garments that resonate with consumers. By staying attuned to market trends and customer preferences, Leicester knitwear manufacturers continuously evolve their product offerings, ensuring that their Sweaters remain fashionable and relevant.

Leicester’s knitwear manufacturers have also made significant strides in sustainability. Recognizing the environmental impact of the fashion industry, they have embraced eco-friendly practices. From using organic and recycled yarns to implementing energy-efficient production processes, these manufacturers are committed to minimizing their carbon footprint and preserving the planet for future

Benefits of Using Salt as a Water Softener Regeneration Media:

Water Softeners are essential devices that help to improve the quality of water in residential and commercial settings. These systems work by removing the Minerals that cause water hardness, such as calcium and magnesium ions. A key component of water softeners is the regeneration process, which involves the use of a regeneration media. One of the most commonly used regeneration media in water softeners is salt, and there are several benefits associated with its use in this context.

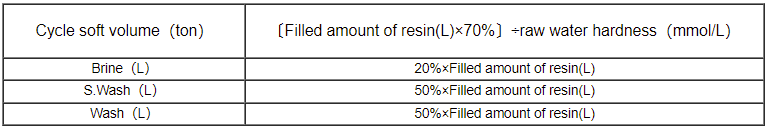

Firstly, salt is highly effective at regenerating water softeners. During the water softening process, the resin beads in the softener trap the hardness minerals. Over time, these resin beads become saturated with the minerals, reducing their ability to soften the water. This is where the regeneration process comes into play. The salt used as a regeneration media helps to clean the resin beads by replacing the trapped minerals with sodium ions. This simple yet effective process restores the resin beads to their original state, ensuring that the water softener continues to function efficiently.

| Model | Category | Water Capacity m3/h | LCD | LED | ICON | DIODE |

| AF2 | Automatic Filter Valve | 2 | O | O | O | O |

| AF2-H | Automatic Filter Valve | 2 | O | O | X | X |

| AF4 | Automatic Filter Valve | 4 | O | O | O | O |

| AF10 | Automatic Filter Valve | 10 | X | O | X | X |

In addition to its effectiveness, salt is also a cost-effective option for water softener regeneration. Compared to other regeneration media, such as potassium chloride, salt is more affordable and widely available. This makes it an economical choice for homeowners and businesses looking to maintain their water softening systems without incurring significant expenses. The affordability of salt as a regeneration media makes it accessible to a wide range of consumers, contributing to its widespread use in the water treatment industry.

Furthermore, salt is known for its stability and reliability as a regeneration media. When properly used in water softeners, salt can provide consistent and predictable regeneration results. This reliability is crucial for ensuring that the water softening system operates effectively and delivers high-quality softened water. Whether it’s a small residential water softener or a large-scale commercial system, salt as a regeneration media can be relied upon to deliver the desired outcomes consistently.

Another benefit of using salt as a water softener regeneration media is its compatibility with most water softener systems. Salt-based regeneration is a well-established method that is supported by a wide range of water softener manufacturers. This means that consumers have the flexibility to choose from various water softener models, knowing that salt can be used effectively for regeneration across different systems. The compatibility of salt as a regeneration media adds to its appeal as a practical and versatile option for maintaining water softeners.

In conclusion, the benefits of using salt as a water softener regeneration media are clear. Its effectiveness, cost-efficiency, stability, and compatibility make it a popular choice for maintaining water softening systems. Whether used in residential or commercial settings, salt stands out as a reliable and practical regeneration media that contributes to the overall