Table of Contents

Lợi ích của máy dán keo tự động để lắp ráp hộp

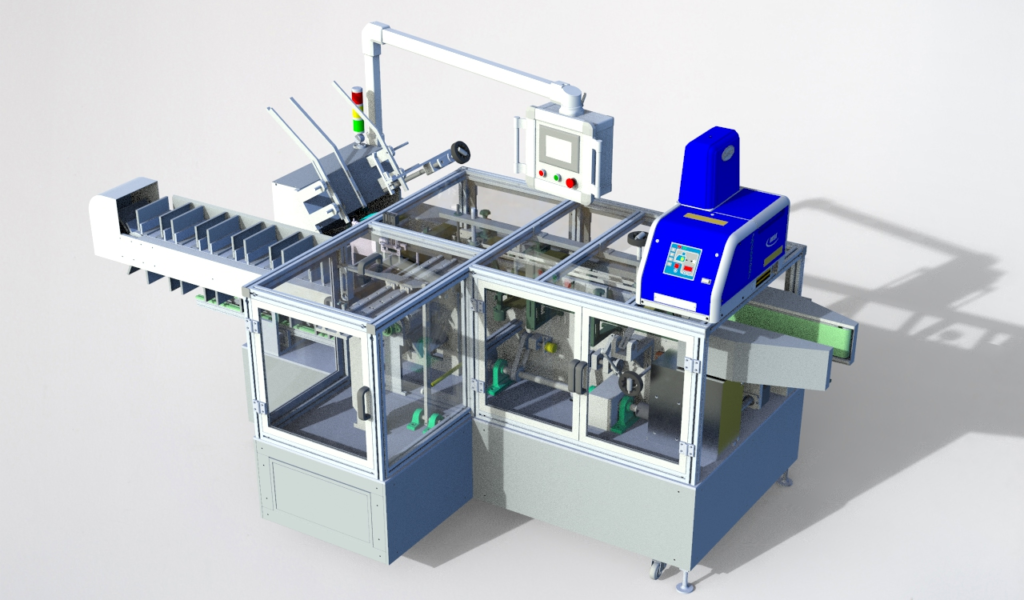

Trong thế giới đóng gói và lắp ráp phát triển nhanh chóng, hiệu quả và độ chính xác là điều tối quan trọng. Trong số các loại máy móc khác nhau được sử dụng trong các quy trình này, máy dán tự động nổi bật nhờ khả năng sắp xếp hợp lý việc lắp ráp hộp với độ chính xác và tốc độ. Những máy này cung cấp một loạt các tính năng được thiết kế để tối ưu hóa quá trình dán, đảm bảo kết quả nhất quán đồng thời giảm thiểu lao động thủ công. Hiểu được các tính năng chính của những máy dán này có thể làm sáng tỏ lợi ích và vai trò không thể thiếu của chúng trong sản xuất hiện đại.

Trọng tâm của máy dán tự động là khả năng bôi keo chính xác. Được trang bị công nghệ tiên tiến, những chiếc máy này có thể kiểm soát lượng và sự phân bổ keo, đảm bảo độ phủ đồng đều trên các bề mặt cần dán. Ứng dụng chính xác này không chỉ nâng cao tính toàn vẹn về cấu trúc của hộp mà còn giảm thiểu lãng phí chất kết dính, giúp tiết kiệm chi phí cho nhà sản xuất.

Moreover, automatic Gluing Machines offer versatility in accommodating various box sizes and designs. Adjustable settings allow for customization according to specific requirements, enabling manufacturers to produce a diverse range of boxes with ease. Whether it’s a small, intricate design or a large, sturdy container, these machines can adapt to the task at hand, thereby enhancing production flexibility and scalability.

Another notable feature of automatic gluing machines is their efficiency in handling high volumes of production. With rapid glue application and quick drying times, these machines can significantly accelerate the assembly process, thereby increasing output and meeting tight deadlines. This efficiency not only boosts productivity but also allows manufacturers to fulfill orders promptly, maintaining customer satisfaction and competitiveness in the market.

Furthermore, automatic gluing machines are equipped with intuitive controls and user-friendly interfaces, facilitating ease of operation. Operators can easily navigate through the settings, monitor the process, and make adjustments as needed, minimizing the risk of errors and downtime. This accessibility not only enhances operational efficiency but also reduces the need for extensive training, making these machines accessible to a wide range of users.

In addition to efficiency and precision, automatic gluing machines prioritize Safety in their design. Incorporating features such as emergency stop Buttons, protective guards, and automated safety protocols, these machines mitigate the risk of accidents and injuries in the workplace. By ensuring a safe working Environment, manufacturers can uphold regulatory compliance and protect the well-being of their employees.

Moreover, automatic gluing machines offer reliability and consistency in performance. Built with durable materials and robust components, these machines are designed to withstand continuous operation with minimal maintenance requirements. This reliability minimizes the likelihood of downtime and disruptions in production, ensuring uninterrupted workflow and maximizing uptime for manufacturers.

In conclusion, the features of automatic gluing machines make them indispensable assets in box assembly operations. From precision glue application to versatility in accommodating various box sizes, these machines offer numerous benefits that enhance efficiency, productivity, and safety in manufacturing processes. By investing in automatic gluing machines, manufacturers can optimize their operations, reduce costs, and maintain a competitive edge in today’s dynamic market landscape.

Understanding the Key Features of Modern Gluing Machines for Box Production

In the world of packaging production, efficiency and precision are paramount. Among the myriad of machinery employed in this industry, the gluing machine stands out as a critical component for box production. Modern gluing machines have evolved significantly, incorporating advanced features to meet the demands of today’s packaging requirements. Understanding these key features is essential for manufacturers seeking to optimize their box production processes.

At the heart of any gluing machine is its adhesive application system. Traditional methods relied on manual application, which was time-consuming and prone to inconsistencies. However, modern gluing machines are equipped with automated adhesive application systems, ensuring uniform glue distribution across the box surfaces. This not only improves efficiency but also enhances the quality and consistency of the final product.

Precision is a hallmark of modern gluing machines, thanks to advancements in technology. These machines are equipped with precise control systems that allow for accurate adjustment of glue application parameters such as flow rate, temperature, and pressure. This level of control ensures that the right amount of adhesive is applied to each part of the box, minimizing waste and reducing production costs.

Versatility is another key feature of modern gluing machines. With the increasing diversity of packaging designs and materials, manufacturers require equipment that can adapt to various production requirements. Modern gluing machines are designed to handle a wide range of box sizes, shapes, and materials, from corrugated cardboard to rigid chipboard. Additionally, they can accommodate different types of adhesives, including hot melt, cold glue, and pressure-sensitive adhesives, providing flexibility in production processes.

Efficiency is paramount in today’s competitive manufacturing landscape, and modern gluing machines are designed with this in mind. These machines are equipped with features such as quick changeover capabilities, allowing for rapid switching between different box designs or production runs. This minimizes downtime and maximizes productivity, enabling manufacturers to meet tight deadlines and customer demands.

Automation is revolutionizing the packaging industry, and gluing machines are no exception. Modern gluing machines feature advanced automation capabilities, including robotic arms and computerized control systems. These automation technologies streamline the production process, reducing the need for manual intervention and improving overall efficiency and accuracy.

Quality control is essential in packaging production, and modern gluing machines incorporate features to ensure the integrity of the final product. From integrated inspection systems that detect defects in real-time to precise registration mechanisms that ensure proper alignment of box components, these machines are equipped to maintain the highest standards of quality throughout the production process.

In conclusion, modern gluing machines represent the pinnacle of technology and innovation in the packaging industry. With their advanced features and capabilities, these machines offer manufacturers the tools they need to produce high-quality boxes efficiently and cost-effectively. By understanding the key features of modern gluing machines, manufacturers can make informed decisions when selecting equipment for their production facilities, ultimately driving success and competitiveness in the market.

Enhancing Efficiency and Quality: Optimizing Gluing Machine Features for Box Manufacturing

In the realm of box manufacturing, the efficiency and quality of production are paramount. One key component that significantly impacts both aspects is the gluing machine. Gluing machines play a crucial role in securely and precisely sealing boxes, ensuring they withstand the rigors of handling and transportation while maintaining a neat and professional appearance. To achieve optimal results, it’s essential to understand the features that contribute to the effectiveness of these machines.

First and foremost, precision is fundamental in box manufacturing. Gluing machines equipped with precise adhesive application mechanisms ensure uniformity in glue distribution, preventing uneven bonding or excess adhesive that can compromise the integrity of the boxes. This precision not only enhances the aesthetic appeal of the finished product but also contributes to its structural robustness, reducing the likelihood of premature wear or damage during transit.

Moreover, versatility is a key consideration in modern manufacturing environments. Gluing machines that offer flexibility in terms of adhesive types and application methods enable manufacturers to adapt to varying production requirements. Whether it’s applying hot melt adhesive for rapid bonding or cold glue for superior adhesion on porous materials, a versatile gluing machine ensures compatibility with a diverse range of box materials and specifications, thereby enhancing operational efficiency and accommodating evolving industry trends.

In addition to precision and versatility, efficiency is a critical factor in optimizing production processes. Gluing machines equipped with advanced automation features streamline the box sealing process, minimizing manual intervention and reducing the risk of errors or inconsistencies. Automated systems not only accelerate production throughput but also enhance reliability and repeatability, enabling manufacturers to meet demanding deadlines without compromising on quality standards.

Furthermore, reliability is paramount in industrial settings where downtime can have significant financial implications. Gluing machines engineered for robustness and durability ensure continuous operation even under demanding conditions, minimizing the risk of unplanned maintenance or production disruptions. By investing in reliable equipment, manufacturers can maximize uptime, minimize operational costs, and maintain consistent output Levels to meet customer demands effectively.

Another critical aspect of gluing machine features is ease of maintenance and serviceability. Machines designed for accessibility and user-friendly maintenance procedures enable swift troubleshooting and repair, minimizing downtime and optimizing overall equipment effectiveness. Additionally, comprehensive service and support offerings from manufacturers further enhance operational reliability, providing timely assistance and preventive maintenance to mitigate potential issues and prolong equipment lifespan.

Moreover, sustainability has emerged as a key consideration in modern manufacturing practices. Gluing machines that incorporate eco-friendly features such as energy-efficient operation and recyclable materials contribute to reducing environmental impact while aligning with corporate sustainability goals. By adopting sustainable technologies, manufacturers not only demonstrate their commitment to environmental stewardship but also realize cost savings through reduced energy consumption and waste generation.

In conclusion, the features of gluing machines for box manufacturing play a pivotal role in enhancing efficiency and quality while addressing the evolving needs of the industry. Precision, versatility, efficiency, reliability, ease of maintenance, and sustainability are key considerations that drive the design and development of these machines. By investing in advanced gluing technologies that prioritize these features, manufacturers can optimize their production processes, minimize costs, and deliver superior-quality boxes that meet the demands of today’s dynamic market landscape.