Table of Contents

Benefits of Warm Mix Asphalt Blend Additives

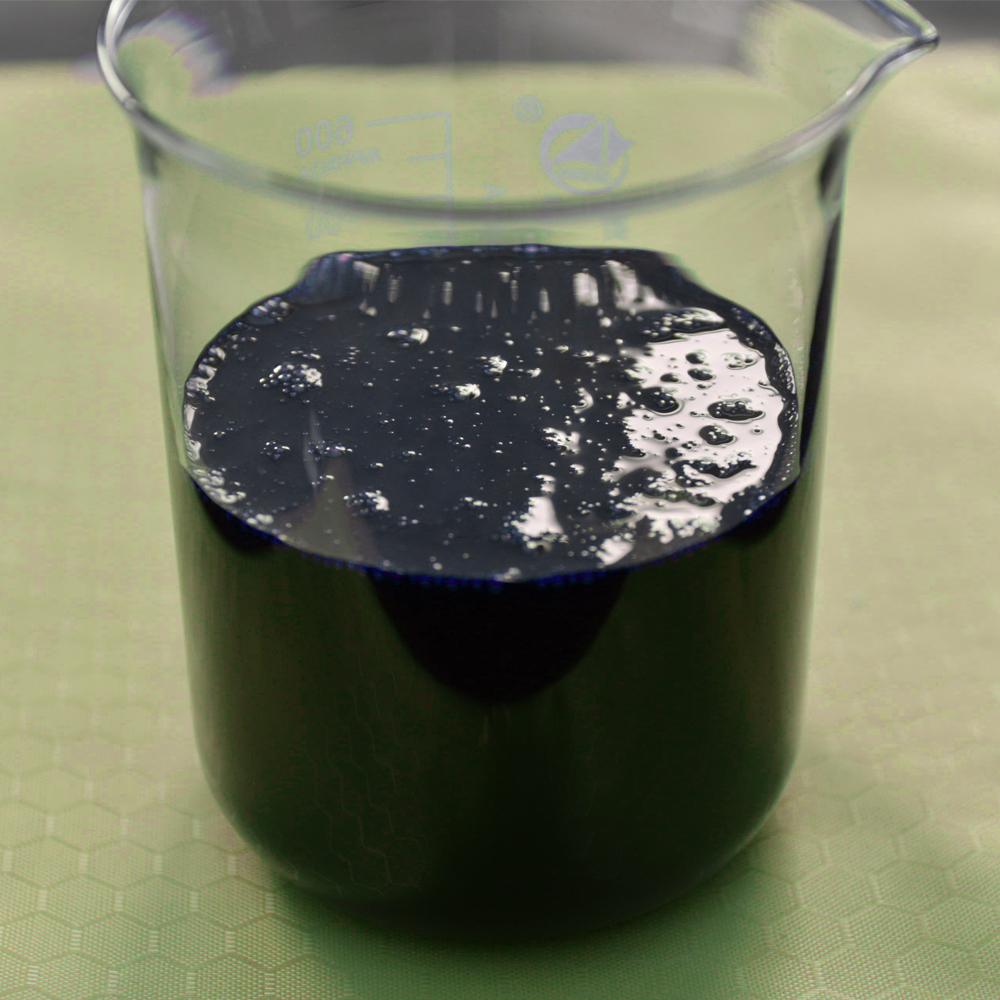

Warm mix asphalt blend additives are becoming increasingly popular in the construction industry due to their numerous benefits. These additives are designed to lower the production and placement temperatures of asphalt mixtures, resulting in a more sustainable and environmentally friendly paving solution. In this article, we will explore the benefits of warm mix asphalt blend additives, with a focus on bitumen modifiers.

| Nr. | Article Name |

| 1 | Warm Mixing asphalt improvement agents |

One of the key advantages of warm mix asphalt blend additives is their ability to reduce energy consumption during the production process. By lowering the mixing and compaction temperatures of asphalt mixtures, these additives can significantly decrease the amount of fuel needed to heat the materials. This not only helps to reduce greenhouse gas emissions, but also lowers the overall cost of production, making warm mix asphalt a more cost-effective paving solution.

In addition to reducing energy consumption, warm mix asphalt blend additives can also improve the workability of asphalt mixtures. By lowering the viscosity of the binder, these additives make it easier to mix and compact the materials, resulting in a smoother and more uniform pavement surface. This can help to reduce the occurrence of segregation and improve the overall quality and durability of the pavement.

Another benefit of warm mix asphalt blend additives is their ability to extend the paving season. Because these additives allow for lower production temperatures, asphalt mixtures can be produced and placed in colder weather conditions, extending the construction season and allowing for more flexibility in scheduling paving projects. This can help to reduce downtime and delays, ultimately saving time and money for contractors and project owners.

Bitumen modifiers are a specific type of warm mix asphalt blend additive that are designed to improve the performance and durability of asphalt pavements. These modifiers are typically added to the binder during the production process, where they help to enhance the rheological properties of the asphalt mixture. By modifying the bitumen, these additives can improve the resistance to rutting, cracking, and moisture damage, resulting in a longer-lasting and more resilient pavement.

One of the key benefits of bitumen modifiers is their ability to improve the fatigue resistance of asphalt pavements. Fatigue cracking is a common issue in asphalt pavements, especially in high-traffic areas where repeated loading and heavy Truck traffic can cause the pavement to crack and deteriorate over time. By adding bitumen modifiers to the asphalt mixture, contractors can improve the flexibility and elasticity of the pavement, helping to reduce the occurrence of fatigue cracking and extend the service life of the pavement.

In conclusion, warm mix asphalt blend additives, particularly bitumen modifiers, offer a wide range of benefits for the construction industry. From reducing energy consumption and improving workability to extending the paving season and enhancing pavement performance, these additives provide a sustainable and cost-effective solution for paving projects of all sizes. By incorporating warm mix asphalt blend additives into their projects, contractors can achieve higher quality pavements that are more durable, resilient, and environmentally friendly.