Table of Contents

Benefits of Incorporating Cellulose Fiber Building Additives in Asphalt

Cellulose fiber building additives are becoming increasingly popular in the construction industry, particularly in the production of asphalt. These additives, derived from wood Pulp fibers, offer a range of benefits that make them a valuable addition to asphalt mixtures. In this article, we will explore the advantages of incorporating cellulose fiber building additives in asphalt and how they can improve the performance and longevity of asphalt pavements.

| Serial Number | Commodity Name |

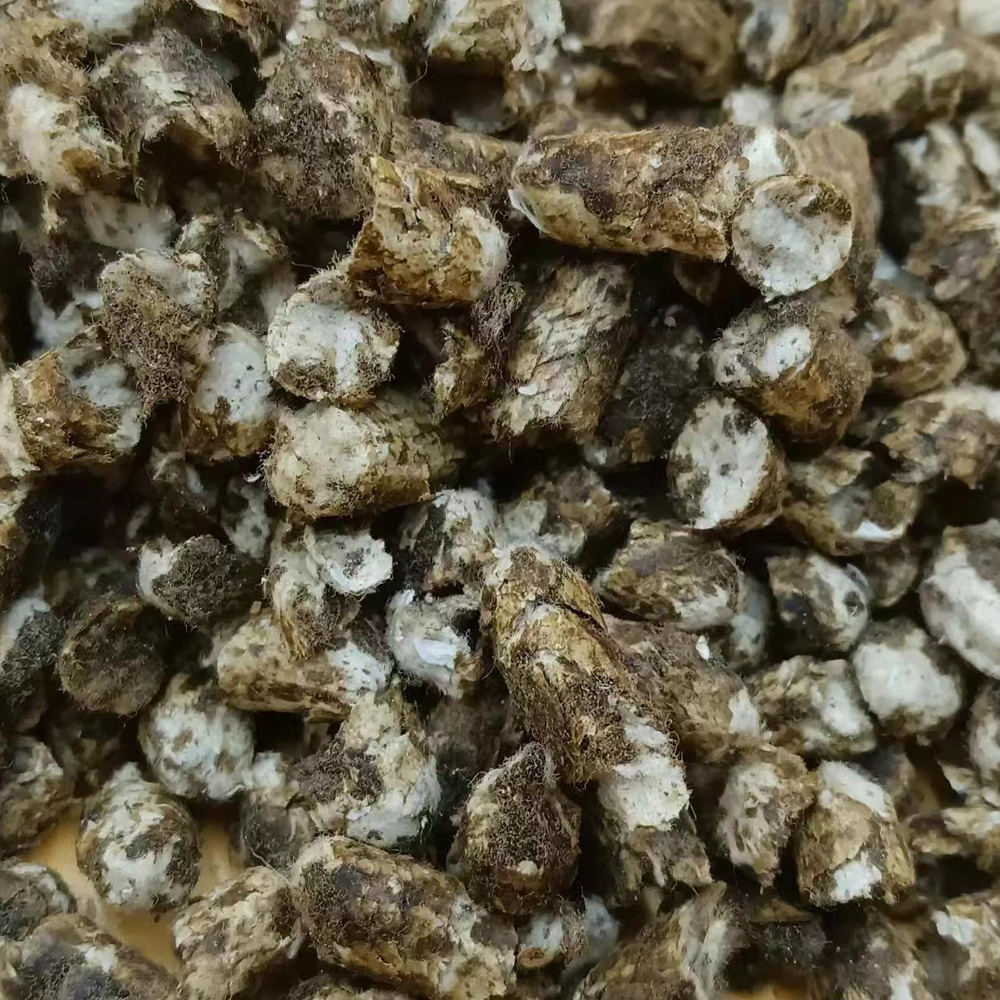

| 1 | Lignin granules |

One of the key benefits of using cellulose fiber building additives in asphalt is their ability to enhance the overall strength and durability of the pavement. The fibers act as a reinforcement agent, helping to bind the asphalt mixture together and prevent cracking and rutting. This results in a more stable and resilient pavement that can withstand heavy traffic loads and harsh weather conditions.

In addition to improving the strength of the pavement, cellulose fiber building additives also help to reduce the occurrence of reflective cracking. These cracks, which often form on the surface of asphalt pavements due to underlying issues such as shrinkage or temperature fluctuations, can compromise the integrity of the pavement and Lead to costly repairs. By incorporating cellulose fibers into the asphalt mixture, contractors can minimize the risk of reflective cracking and extend the lifespan of the pavement.

Another advantage of using cellulose fiber building additives in asphalt is their ability to improve the workability of the mixture during the construction process. The fibers help to distribute the asphalt binder more evenly throughout the mixture, resulting in a smoother and more uniform pavement surface. This not only enhances the aesthetic appeal of the pavement but also makes it easier to achieve the desired compaction Levels, ensuring a more consistent and durable pavement.

Furthermore, cellulose fiber building additives can help to reduce the overall cost of asphalt pavement construction. By improving the strength and durability of the pavement, contractors can minimize the need for frequent repairs and maintenance, saving both time and money in the long run. Additionally, the enhanced workability of the asphalt mixture can lead to faster and more efficient construction processes, further reducing labor and equipment costs.

Overall, the benefits of incorporating cellulose fiber building additives in asphalt are clear. From improving the strength and durability of the pavement to reducing reflective cracking and enhancing workability, these additives offer a range of advantages that can help contractors achieve high-quality and long-lasting asphalt pavements. By utilizing cellulose fibers in their asphalt mixtures, contractors can create pavements that are not only more resilient and cost-effective but also more sustainable and environmentally friendly.

In conclusion, cellulose fiber building additives are a valuable addition to asphalt mixtures, offering a range of benefits that can improve the performance and longevity of asphalt pavements. By incorporating these additives into their construction projects, contractors can create stronger, more durable, and more cost-effective pavements that will stand the test of time.

Sustainable Construction Practices: Utilizing Wood Pulp Fibers as Building Additives

Cellulose fiber building additives, derived from wood pulp fibers, are gaining popularity in the construction industry as a sustainable alternative to traditional building materials. These fibers are being used in a variety of applications, including asphalt, to improve the performance and longevity of structures while reducing environmental impact.

One of the key benefits of using cellulose fiber building additives is their ability to enhance the strength and durability of construction materials. When added to asphalt, these fibers help to improve the overall stability and resistance to cracking, which can extend the lifespan of roads and other paved surfaces. This not only saves money on maintenance and repairs but also reduces the need for new materials to be extracted and processed, lowering the carbon footprint of construction projects.

In addition to their structural benefits, cellulose fiber building additives also offer environmental advantages. Wood pulp fibers are renewable resources that can be sustainably harvested and processed, making them a more eco-friendly option compared to traditional building materials. By incorporating these fibers into construction projects, builders can reduce their reliance on non-renewable resources and help mitigate the environmental impact of their work.

Furthermore, cellulose fiber building additives can improve the overall sustainability of construction practices by reducing waste and energy consumption. These fibers can be easily recycled and reused in other applications, minimizing the amount of material that ends up in landfills. Additionally, the production process for cellulose fiber building additives requires less energy and resources compared to traditional building materials, further reducing the environmental footprint of construction projects.

Another advantage of using cellulose fiber building additives is their versatility and compatibility with a wide range of construction materials. These fibers can be easily mixed with asphalt, concrete, and other building materials without compromising their performance or structural integrity. This flexibility allows builders to incorporate cellulose fiber building additives into a variety of construction projects, from roads and bridges to buildings and infrastructure.

Overall, cellulose fiber building additives offer a sustainable and cost-effective solution for improving the performance and longevity of construction materials. By utilizing these fibers in building projects, builders can reduce their environmental impact, lower costs, and enhance the overall sustainability of their work. As the construction industry continues to prioritize sustainability and eco-friendly practices, cellulose fiber building additives are poised to play a key role in shaping the future of construction.