Table of Contents

The Impact of Technological Progress on Oil Casing Manufacturing

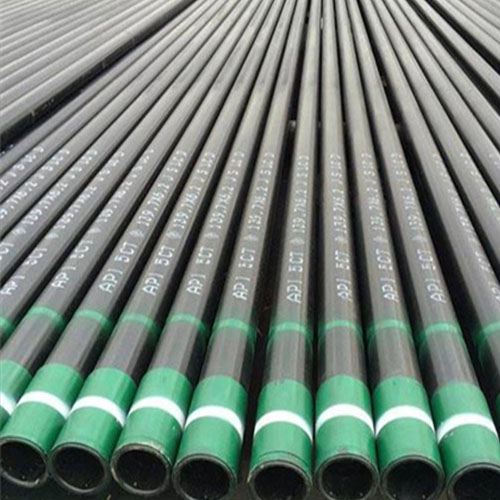

Technological progress has had a significant impact on the manufacturing of oil casing in the oil and gas industry. Oil casing plays a crucial role in the drilling and extraction of oil and gas from underground reservoirs. As technology continues to advance, the production of oil casing has evolved to meet the demands of the industry.

One of the key advancements in oil casing manufacturing is the use of advanced materials. Traditionally, oil casing was made from Carbon Steel, which provided adequate strength and durability. However, with the development of new materials such as high-strength steel and corrosion-resistant alloys, oil casing can now withstand higher pressures and harsher environments. These materials have revolutionized the industry by allowing for deeper drilling and more efficient extraction of oil and gas reserves.

In addition to advanced materials, technological progress has also led to improvements in manufacturing processes. Automation and robotics have streamlined production, reducing Lead times and increasing efficiency. Computer-aided design (CAD) and computer-aided manufacturing (CAM) Software have enabled manufacturers to design and produce oil casing with greater precision and accuracy. This has resulted in higher quality products that meet the stringent requirements of the industry.

Furthermore, technological advancements have also led to the development of new coating and finishing techniques for oil casing. Coatings such as epoxy, Zinc, and Polymer have been introduced to protect the casing from corrosion and extend its lifespan. These coatings not only improve the performance of the casing but also reduce maintenance costs for operators.

Another significant impact of technological progress on oil casing manufacturing is the trend towards customization and tailor-made solutions. With the use of advanced software and machinery, manufacturers can now produce oil casing that is specifically designed to meet the unique requirements of each well. This customization allows for better performance and efficiency, ultimately leading to increased productivity and profitability for operators.

Moreover, technological progress has also facilitated the integration of Sensors and monitoring devices into oil casing. These sensors can provide real-time data on the condition of the casing, allowing operators to detect potential issues before they escalate. This proactive approach to maintenance and monitoring can help prevent costly downtime and ensure the Safety and integrity of the well.

Overall, technological progress has had a profound impact on the manufacturing of oil casing in the oil and gas industry. From advanced materials and manufacturing processes to customization and monitoring capabilities, technology has revolutionized the way oil casing is produced and utilized. As the industry continues to evolve, it is clear that technological advancements will play a crucial role in driving innovation and efficiency in oil casing manufacturing.