Table of Contents

The Art of Customizing Men’s Knitted Sweaters on the Factory Floor

Customizing men’s knitted sweaters on the factory floor is a meticulous process that requires skill, precision, and attention to detail. From selecting the right Yarn and color to creating intricate patterns and designs, every step in the customization process plays a crucial role in producing high-quality, personalized sweaters that meet the unique preferences of each customer.

The first step in customizing men’s knitted sweaters is selecting the right yarn. The type of yarn used can greatly impact the look and feel of the final product, so it is important to choose a high-quality yarn that is both durable and comfortable to wear. Different yarns also have different properties, such as warmth, softness, and breathability, so selecting the right yarn is essential in creating a sweater that meets the customer’s specific needs and preferences.

| Nr. | Commodity Name | Fabric name | Supply model |

| 2 | knitted jumper | SPANDEX | Sweater Bespoke customization |

| Encoding | Product type | Fabric classification | Supply model |

| 1.1 | sweater cardigans | LUREX | Sweater Custom-fit |

Once the yarn has been selected, the next step is choosing the color or colors for the sweater. Color plays a significant role in the overall design of the sweater and can greatly influence its aesthetic appeal. Whether the customer prefers a classic neutral tone or a bold, vibrant color, the factory floor must have a wide range of color options available to accommodate a variety of preferences.

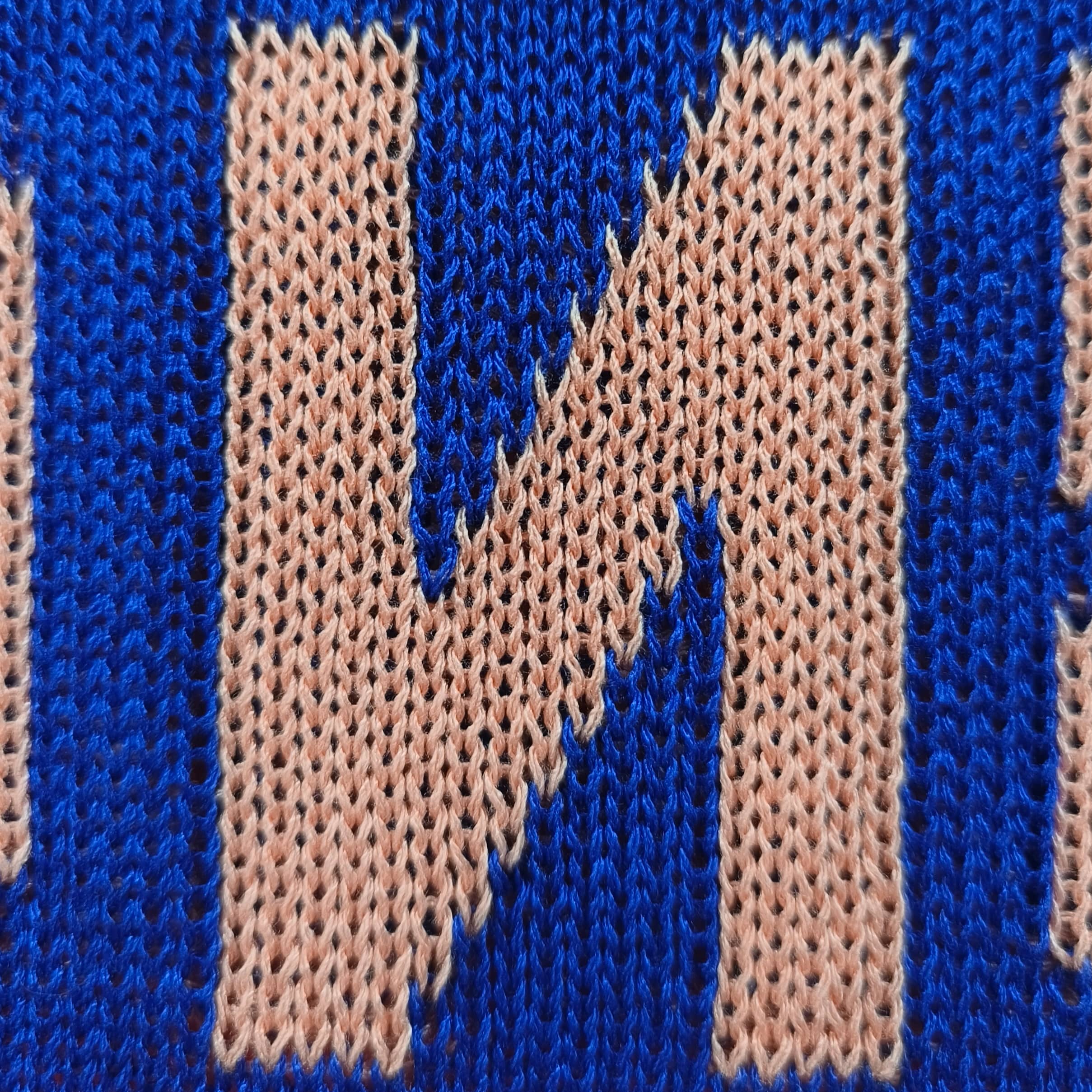

After selecting the yarn and color, the next step in customizing men’s knitted sweaters is creating the design. This is where the skill and expertise of the factory floor’s knitters come into play. Whether it’s a simple striped pattern or a more complex Fair Isle design, the knitters must carefully follow the pattern instructions to ensure that the design is executed accurately and precisely.

In addition to creating the design, the knitters must also pay close attention to the fit and sizing of the sweater. Customizing a sweater to fit a specific individual requires precise measurements and adjustments to ensure that the final product is comfortable and flattering. This may involve making alterations to the pattern or adjusting the tension of the stitches to achieve the desired fit.

Throughout the customization process, quality control is essential to ensure that each sweater meets the factory’s high standards of craftsmanship. This involves inspecting the yarn for any defects or inconsistencies, checking the accuracy of the design and pattern, and verifying that the sizing and fit are correct. Any issues or imperfections must be addressed and corrected before the sweater is completed and ready for delivery to the customer.

In conclusion, customizing men’s knitted sweaters on the factory floor is a labor-intensive process that requires skill, precision, and attention to detail. From selecting the right yarn and color to creating intricate designs and ensuring a perfect fit, every step in the customization process is essential in producing high-quality, personalized sweaters that meet the unique preferences of each customer. By following a meticulous process and maintaining high standards of craftsmanship, the factory floor can create custom sweaters that are not only stylish and comfortable but also reflect the individuality and personal style of the wearer.