Table of Contents

Benefits of Using Plastic Coated Steel Wire Rope

Steel wire rope is a versatile and durable material that is commonly used in a variety of industries for lifting, rigging, and towing applications. One popular option for steel wire rope is plastic coated steel wire rope, which offers a number of benefits over traditional uncoated wire rope.

One of the main advantages of plastic coated steel wire rope is its enhanced durability and resistance to corrosion. The plastic coating acts as a protective barrier, shielding the steel wire rope from moisture, Chemicals, and other corrosive elements that can cause rust and deterioration. This makes plastic coated steel wire rope ideal for outdoor use or in environments where exposure to harsh conditions is a concern.

In addition to its corrosion resistance, plastic coated steel wire rope is also more resistant to abrasion and wear. The plastic coating helps to reduce friction between the wire rope and other surfaces, which can help to extend the lifespan of the rope and reduce the need for frequent replacements. This can result in cost savings over time, as well as increased Safety and reliability in lifting and rigging applications.

Another benefit of plastic coated steel wire rope is its improved handling and grip. The plastic coating provides a smooth and comfortable surface that is easier to handle and less likely to cause injury or strain to the user. This can be especially important in applications where workers are required to handle the wire rope manually, such as in towing or rigging operations.

Plastic coated steel wire rope is also available in a variety of colors, which can help to improve visibility and safety on job sites. Brightly colored coatings can make the wire rope easier to see in low light conditions or in busy work areas, reducing the risk of accidents and injuries. This can be particularly important in industries where safety is a top priority, such as construction, mining, or marine operations.

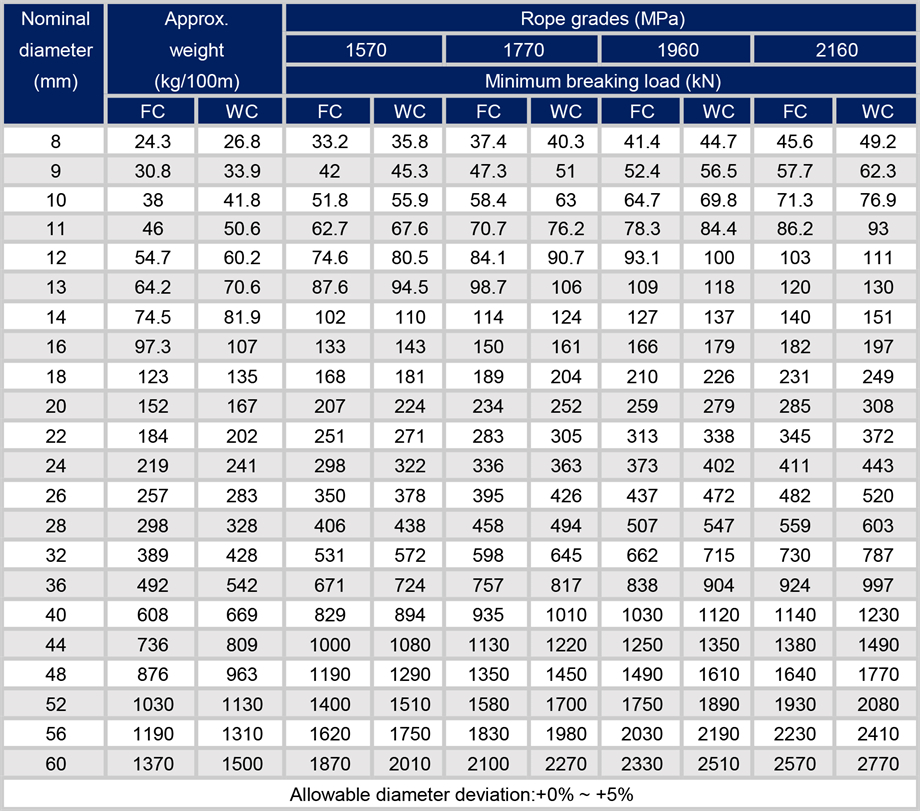

When it comes to choosing the right plastic coated steel wire rope for your application, there are a few key factors to consider. The diameter of the wire rope, the strength and flexibility of the steel core, and the thickness and material of the plastic coating all play a role in determining the performance and durability of the rope. It is important to select a wire rope that is appropriate for the specific load and conditions of your application, as using the wrong type of wire rope can compromise safety and efficiency.

In conclusion, plastic coated steel wire rope offers a number of benefits over traditional uncoated wire rope, including enhanced durability, resistance to corrosion and abrasion, improved handling and grip, and increased visibility and safety. By choosing the right plastic coated steel wire rope for your application, you can ensure reliable performance and peace of mind in your lifting, rigging, or towing operations.

How to Properly Maintain 5/8 Stainless Steel Wire Rope

Steel wire rope is a versatile and durable material that is commonly used in a variety of applications, from construction to marine industries. One popular type of steel wire rope is the 5/8 stainless steel wire rope, known for its strength and corrosion resistance. Proper maintenance of this type of wire rope is essential to ensure its longevity and performance.

To properly maintain 5/8 stainless steel wire rope, it is important to regularly inspect the rope for any signs of wear or damage. This can include checking for broken strands, kinks, or corrosion. Any damaged sections should be replaced immediately to prevent further deterioration of the rope.

In addition to visual inspections, it is also important to regularly clean the wire rope to remove dirt, debris, and other contaminants that can cause corrosion. This can be done using a mild detergent and water, followed by a thorough rinse and drying of the rope. Avoid using harsh chemicals or abrasive Cleaners, as these can damage the stainless steel material.

After cleaning, it is recommended to lubricate the wire rope to reduce friction and prevent corrosion. There are various types of lubricants available for steel wire rope, so be sure to choose one that is compatible with stainless steel. Apply the lubricant evenly along the length of the rope, making sure to work it into the strands for maximum effectiveness.

In addition to regular cleaning and lubrication, it is also important to store 5/8 stainless steel wire rope properly when not in use. This can help prevent damage from exposure to the elements and prolong the life of the rope. Store the wire rope in a dry, well-ventilated area away from moisture and direct sunlight. Avoid storing the rope in a coiled or twisted position, as this can cause kinks and damage to the strands.

When using 5/8 stainless steel wire rope in outdoor or marine environments, it is important to take extra precautions to protect the rope from harsh conditions. This can include using protective coatings or Sleeves to prevent abrasion and corrosion, as well as regularly inspecting the rope for signs of wear or damage.

In conclusion, proper maintenance of 5/8 stainless steel wire rope is essential to ensure its longevity and performance. By regularly inspecting, cleaning, lubricating, and storing the rope properly, you can help prevent damage and prolong the life of the rope. Taking these simple steps can help you get the most out of your steel wire rope and ensure safe and reliable operation in a variety of applications.