Table of Contents

Benefits of Using 18mm Steel Wire Rope in Construction Projects

Steel wire rope is a crucial component in many construction projects, providing strength, durability, and reliability in a variety of applications. When it comes to choosing the right steel wire rope for your project, size matters. In this article, we will explore the benefits of using 18mm steel wire rope in construction projects.

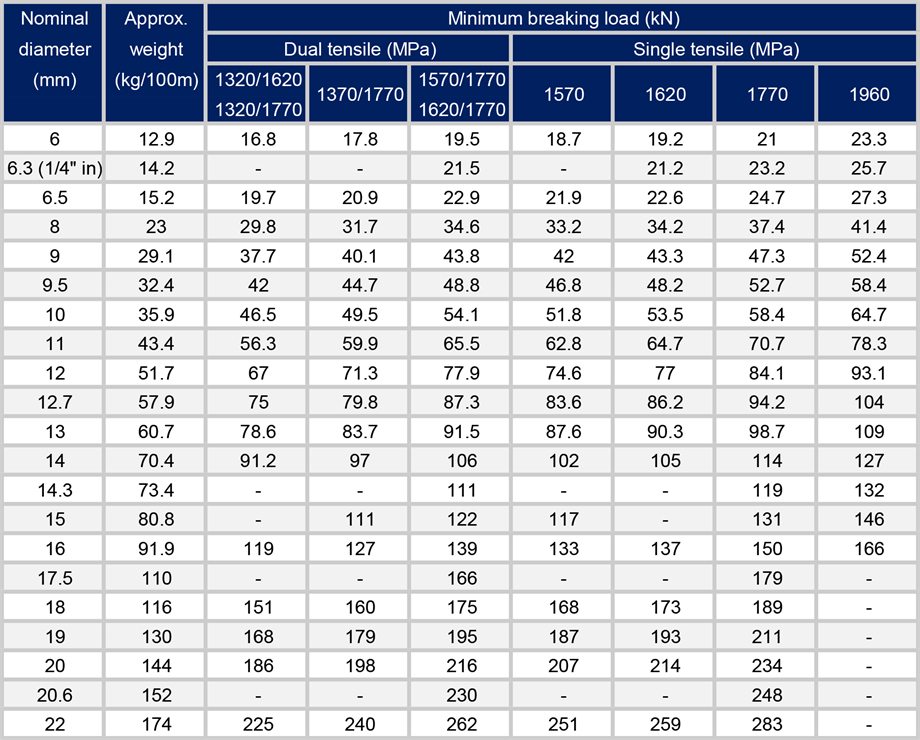

One of the primary advantages of using 18mm steel wire rope is its superior strength. With a larger diameter than smaller ropes, 18mm steel wire rope can handle heavier loads and withstand greater stress and tension. This makes it an ideal choice for applications where Safety and reliability are paramount, such as lifting and hoisting operations.

In addition to its strength, 18mm steel wire rope offers excellent durability. Constructed from high-quality steel, this rope is designed to withstand harsh environmental conditions, including extreme temperatures, moisture, and corrosion. This means that it can be used in a wide range of outdoor and industrial settings without fear of degradation or failure.

Another benefit of using 18mm steel wire rope is its versatility. With a larger diameter, this rope is well-suited for a variety of applications, from heavy-duty lifting and rigging to structural support and anchoring. Its flexibility and adaptability make it a valuable asset on construction sites, where it can be used for everything from securing scaffolding to lifting materials to great heights.

Furthermore, 18mm steel wire rope is easy to work with, thanks to its smooth surface and pliable construction. This makes it simple to handle and manipulate, even in tight spaces or challenging environments. Whether you are rigging a crane or securing a load, this rope offers the flexibility and maneuverability needed to get the job done efficiently and safely.

In addition to its practical benefits, 18mm steel wire rope is also cost-effective. While larger ropes may have a higher upfront cost, their superior strength and durability can result in long-term savings by reducing the need for frequent replacements and repairs. This can help to lower overall project costs and improve the efficiency and productivity of your construction operations.

Overall, the benefits of using 18mm steel wire rope in construction projects are clear. From its superior strength and durability to its versatility and cost-effectiveness, this rope offers a wide range of advantages that make it an essential tool for any construction site. Whether you are lifting heavy loads, securing structures, or rigging equipment, 18mm steel wire rope provides the strength, reliability, and performance you need to get the job done right.

Maintenance Tips for Extending the Lifespan of 18mm Steel Wire Rope

Steel wire rope is a crucial component in various industries, including construction, mining, and transportation. Its durability and strength make it an essential tool for lifting heavy loads and securing structures. However, like any other equipment, steel wire rope requires regular maintenance to ensure its longevity and optimal performance. In this article, we will discuss some maintenance tips for extending the lifespan of 18mm steel wire rope.

One of the most important maintenance tasks for steel wire rope is regular inspection. Inspecting the rope for signs of wear and tear, such as broken wires, kinks, or corrosion, can help prevent accidents and ensure the safety of workers. It is recommended to inspect the rope before each use and replace any damaged sections immediately.

Another crucial aspect of steel wire rope maintenance is lubrication. Proper lubrication can help reduce friction between the wires, preventing premature wear and extending the rope’s lifespan. It is essential to use a high-quality lubricant specifically designed for steel wire rope and apply it regularly to ensure smooth operation.

In addition to regular inspection and lubrication, proper storage of steel wire rope is also essential for maintaining its longevity. Storing the rope in a dry, well-ventilated area away from moisture and direct sunlight can help prevent corrosion and degradation. It is also important to avoid storing the rope in areas with high temperatures or humidity, as this can accelerate wear and reduce its lifespan.

When using steel wire rope, it is crucial to follow the manufacturer’s guidelines for safe operation. Overloading the rope or using it in ways it was not intended for can cause damage and shorten its lifespan. It is important to always use the appropriate size and type of rope for the task at hand and avoid exceeding its maximum load capacity.

Regular cleaning is another important maintenance task for steel wire rope. Dirt, debris, and other contaminants can accumulate on the surface of the rope, causing abrasion and corrosion. Cleaning the rope with a mild detergent and water can help remove these contaminants and prevent damage. It is important to dry the rope thoroughly after cleaning to prevent rust and corrosion.

In conclusion, proper maintenance is essential for extending the lifespan of 18mm steel wire rope. Regular inspection, lubrication, proper storage, following manufacturer guidelines, and regular cleaning are all important aspects of maintaining the rope’s durability and performance. By following these maintenance tips, you can ensure the safety of workers, prevent accidents, and maximize the lifespan of your steel wire rope. Remember, a well-maintained rope is a safe rope.

Comparison of Different Types of 18mm Steel Wire Rope for Various Applications

Steel wire ropes are essential components in various industries, including construction, mining, marine, and transportation. They are used for lifting heavy loads, securing structures, and providing support in challenging environments. When it comes to selecting the right steel wire rope for a specific application, size plays a crucial role. In this article, we will compare different types of 18mm steel wire ropes and their suitability for various applications.

One of the most common types of 18mm steel wire rope is the 6×19 construction. This type of wire rope consists of six strands with 19 wires in each strand. The 6×19 construction offers a good balance between flexibility and strength, making it suitable for general lifting and hoisting applications. It is also resistant to abrasion and fatigue, making it a durable choice for heavy-duty operations.

Another popular option is the 6×36 construction, which features six strands with 36 wires in each strand. This type of wire rope offers higher flexibility compared to the 6×19 construction, making it ideal for applications that require bending and twisting. The 6×36 construction is commonly used in crane operations, Fishing, and marine applications where flexibility is essential.

For applications that require maximum strength and durability, the 6×37 construction is a suitable choice. This type of wire rope consists of six strands with 37 wires in each strand, providing superior strength and resistance to wear and tear. The 6×37 construction is commonly used in heavy lifting operations, mining, and oil and gas exploration where safety and reliability are paramount.

In addition to construction type, the material used in the manufacturing of steel wire ropes also plays a significant role in their performance. Stainless Steel wire ropes are known for their corrosion resistance and durability, making them ideal for marine and offshore applications where exposure to harsh environments is common. Galvanized steel wire ropes are coated with a layer of Zinc to protect against corrosion, making them suitable for outdoor applications where moisture and humidity are present.

When selecting an 18mm steel wire rope for a specific application, it is essential to consider factors such as load capacity, flexibility, and resistance to wear and tear. The 6×19 construction is a versatile option that offers a good balance between strength and flexibility, making it suitable for general lifting and hoisting operations. The 6×36 construction provides higher flexibility, making it ideal for applications that require bending and twisting. The 6×37 construction offers maximum strength and durability, making it a reliable choice for heavy-duty operations.

In conclusion, the selection of the right type of 18mm steel wire rope depends on the specific requirements of the application. By considering factors such as construction type and material, it is possible to choose a wire rope that meets the demands of the operation. Whether it is lifting heavy loads, securing structures, or providing support in challenging environments, there is a suitable 18mm steel wire rope available for every application.