Table of Contents

Benefits of Using Stainless Steel Rope Wire in Construction Projects

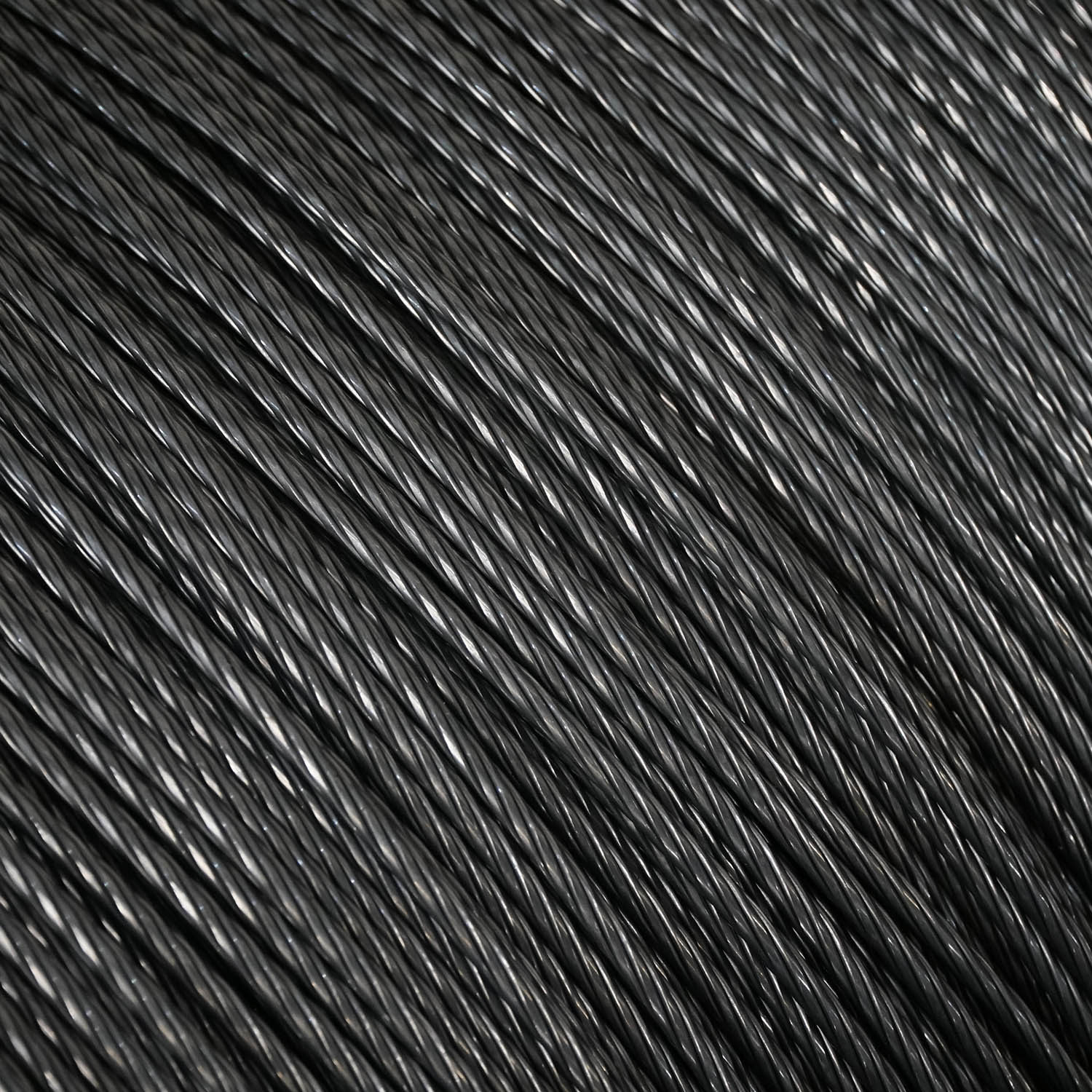

Stainless steel rope wire is a versatile and durable material that is commonly used in construction projects. Its strength and corrosion resistance make it an ideal choice for a wide range of applications, from building facades to suspension bridges. In this article, we will explore the benefits of using stainless steel rope wire in construction projects.

One of the key advantages of stainless steel rope wire is its strength. Stainless steel is a high-strength material that can withstand heavy loads and extreme weather conditions. This makes it an excellent choice for applications where strength and durability are essential, such as in the construction of bridges, high-rise buildings, and other structures that require support and stability.

In addition to its strength, stainless steel rope wire is also highly resistant to corrosion. This is due to the presence of chromium in the steel, which forms a protective Oxide layer on the surface of the material. This oxide layer acts as a barrier against moisture, Chemicals, and other corrosive agents, ensuring that the steel remains in good condition for many years.

Another benefit of using stainless steel rope wire in construction projects is its aesthetic appeal. Stainless steel has a sleek and modern look that can enhance the visual appeal of any structure. Whether used as a support cable for a glass facade or as a decorative element in a building design, stainless steel rope wire can add a touch of elegance and sophistication to any project.

Furthermore, stainless steel rope wire is easy to work with and can be customized to meet the specific requirements of a project. It can be cut, bent, and shaped to fit the desired dimensions, making it a versatile material that can be used in a variety of applications. Whether you need a long, continuous cable for a suspension bridge or a series of shorter cables for a railing system, stainless steel rope wire can be tailored to suit your needs.

In addition to its strength, durability, and aesthetic appeal, stainless steel rope wire is also a sustainable choice for construction projects. Stainless steel is 100% recyclable, meaning that it can be reused and repurposed at the end of its life cycle. This makes it an environmentally friendly option that can help reduce the carbon footprint of a project and contribute to a more sustainable construction industry.

In conclusion, stainless steel rope wire offers a wide range of benefits for construction projects. Its strength, corrosion resistance, aesthetic appeal, and sustainability make it an ideal choice for a variety of applications. Whether you are building a bridge, a high-rise building, or a decorative structure, stainless steel rope wire can provide the support, durability, and visual appeal you need to bring your project to life.

How to Choose the Right Steel Wire Harness for Your Industrial Needs

Steel wire harnesses are an essential component in many industrial applications, providing a secure and reliable way to organize and protect Electrical Wires and cables. When it comes to choosing the right steel wire harness for your specific needs, there are several factors to consider. From the type of wire rope used to the construction of the harness itself, each element plays a crucial role in ensuring the Safety and efficiency of your industrial operations.

One of the first things to consider when selecting a steel wire harness is the type of wire rope used. Stainless steel wire rope is a popular choice for industrial applications due to its strength, durability, and resistance to corrosion. This type of wire rope is ideal for use in harsh environments where exposure to moisture, chemicals, or extreme temperatures is a concern. Additionally, stainless steel wire rope is known for its high tensile strength, making it a reliable choice for heavy-duty applications.

Another important factor to consider when choosing a steel wire harness is the construction of the harness itself. The design of the harness will determine how well it can protect and organize the wires and cables within it. Look for a harness that features a durable outer casing, such as PVC or nylon, to provide added protection against abrasion and impact. Additionally, consider the layout of the harness, including the number of channels and the spacing between them, to ensure that it can accommodate all of the wires and cables in your industrial system.

In addition to the type of wire rope and construction of the harness, it is also important to consider the manufacturer of the steel wire harness. Look for a reputable company with a proven track record of producing high-quality products that meet industry standards. A reliable manufacturer will be able to provide you with the technical support and expertise needed to select the right harness for your specific needs.

When choosing a steel wire harness for your industrial applications, it is essential to consider the Environment in which it will be used. If your operations involve exposure to harsh chemicals or extreme temperatures, you will need a harness that can withstand these conditions. Additionally, consider the level of flexibility and mobility required for your system, as this will impact the design of the harness.

Ultimately, selecting the right steel wire harness for your industrial needs requires careful consideration of several key factors. From the type of wire rope used to the construction of the harness itself, each element plays a crucial role in ensuring the safety and efficiency of your operations. By working with a reputable manufacturer and considering the specific requirements of your environment, you can choose a steel wire harness that meets your needs and provides reliable performance for years to come.