Table of Contents

Benefits of Splicing Steel Wire Rope

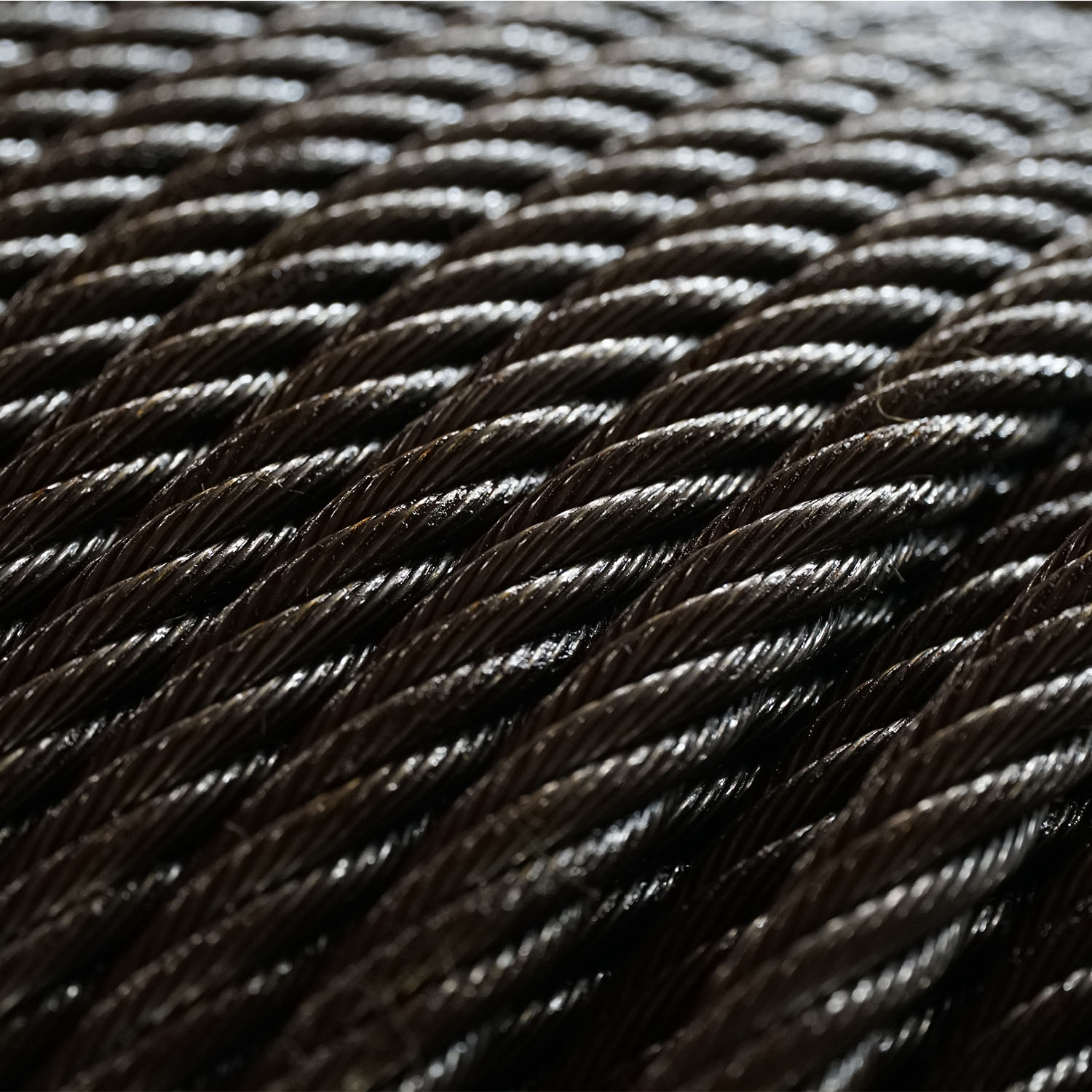

Splicing steel wire rope is a common practice in various industries, including construction, maritime, and transportation. It involves joining two or more strands of steel wire rope together to create a continuous length of rope. This process offers several benefits that make it a preferred method for connecting steel wire ropes.

One of the main advantages of splicing steel wire rope is its strength and durability. When done correctly, splicing creates a seamless connection between the strands, ensuring that the rope can withstand heavy loads and harsh conditions. This makes spliced steel wire ropes ideal for applications where Safety and reliability are paramount, such as lifting and rigging operations.

In addition to its strength, splicing steel wire rope also offers flexibility and versatility. Unlike other methods of connecting ropes, such as using Clamps or fittings, splicing allows for a smooth transition between the strands, reducing the risk of snagging or catching on objects. This flexibility makes spliced steel wire ropes easier to handle and maneuver, making them suitable for a wide range of applications.

Another benefit of splicing steel wire rope is its cost-effectiveness. While the initial investment in splicing tools and equipment may be higher than other methods, the long-term savings can be significant. Spliced steel wire ropes are less likely to fail or break under stress, reducing the need for frequent replacements and repairs. This can result in lower maintenance costs and downtime, ultimately saving businesses time and money in the long run.

Furthermore, splicing steel wire rope can also improve the overall performance of the rope. By creating a seamless connection between the strands, splicing helps distribute the load evenly across the entire length of the rope. This can prevent weak spots or stress points from forming, prolonging the life of the rope and ensuring consistent performance over time.

Additionally, splicing steel wire rope can also enhance safety in the workplace. The smooth, continuous design of spliced ropes reduces the risk of fraying or unraveling, which can pose a hazard to workers and equipment. This can help prevent accidents and injuries, creating a safer working Environment for everyone involved.

Overall, splicing steel wire rope offers a range of benefits that make it a preferred method for connecting ropes in various industries. From its strength and durability to its flexibility and cost-effectiveness, splicing provides a reliable and efficient solution for joining steel wire ropes. By choosing to splice their ropes, businesses can ensure the safety, performance, and longevity of their equipment, ultimately leading to increased productivity and profitability.

Step-by-Step Guide to Splicing Steel Wire Rope

Steel wire rope is a versatile and durable material used in a variety of applications, from construction to maritime industries. One of the key skills required when working with steel wire rope is splicing, which involves joining two ends of rope together to create a continuous loop. Splicing steel wire rope can be a complex process, but with the right tools and techniques, it can be done safely and effectively.

To begin splicing steel wire rope, you will need a few essential tools and materials. These include a fid, which is a tapered tool used to separate the strands of the rope, a marlinspike, which is a pointed tool used to manipulate the strands, and a pair of wire cutters to trim the excess rope. You will also need a length of steel wire rope and some tape to secure the ends of the rope during the splicing process.

The first step in splicing steel wire rope is to unravel the strands at each end of the rope using the fid. Start by inserting the fid between the strands and gently pulling them apart. Be careful not to damage the individual strands as you separate them. Once you have unraveled the strands, use the marlinspike to manipulate them into the desired configuration for splicing.

Next, you will need to interlock the strands at each end of the rope to create a seamless splice. This can be done by weaving the strands together in a specific pattern, such as a crown splice or a long splice. Take your time to ensure that each strand is properly interlocked with the others to create a strong and secure splice.

After interlocking the strands, use the marlinspike to tighten the splice and ensure that it is secure. You may need to adjust the tension of the strands to achieve the desired tightness. Once the splice is tight, use the wire cutters to trim any excess rope and tape the ends to prevent them from unraveling.

Finally, test the splice to ensure that it is strong and secure. Apply pressure to the splice and check for any signs of weakness or slippage. If the splice holds up to the pressure, you can be confident that it has been properly spliced and is ready for use.

In conclusion, splicing steel wire rope is a valuable skill that can be learned with practice and patience. By following these steps and using the right tools and techniques, you can create strong and secure splices that will withstand the rigors of heavy use. Remember to always prioritize safety when working with steel wire rope and seek guidance from experienced professionals if you are unsure about any aspect of the splicing process. With practice and dedication, you can become proficient in splicing steel wire rope and use this valuable skill in a variety of applications.