Table of Contents

Benefits of Using Polymer for Highway Construction

Polymer is a versatile material that has been gaining popularity in the construction industry, particularly for highway and driveway projects. One of the main reasons for this is its durability and longevity. When used in highway construction, polymer can significantly extend the lifespan of the road, reducing the need for frequent repairs and maintenance.

One of the key benefits of using polymer for highway construction is its ability to withstand heavy traffic and harsh weather conditions. Unlike traditional materials like asphalt, polymer is resistant to cracking and rutting, making it ideal for high-traffic areas. This means that roads constructed with polymer are less likely to develop potholes and other defects, resulting in a smoother and safer driving experience for motorists.

| Nr. | Product |

| 1 | for bridge Recycled polyester |

In addition to its durability, polymer is also environmentally friendly. Unlike asphalt, which is made from non-renewable resources like oil, polymer is a sustainable material that can be recycled and reused. This makes it a more eco-friendly option for highway construction, helping to reduce the carbon footprint of road projects.

Another advantage of using polymer for highway construction is its ease of installation. Polymer can be applied quickly and efficiently, reducing construction time and minimizing disruptions to traffic flow. This is especially important for highway projects, where delays can cause significant inconvenience to motorists and businesses.

Furthermore, polymer is a cost-effective option for highway construction. While the initial cost of using polymer may be higher than traditional materials, the long-term savings are significant. Roads constructed with polymer require less maintenance and repair, resulting in lower overall costs over the lifespan of the road.

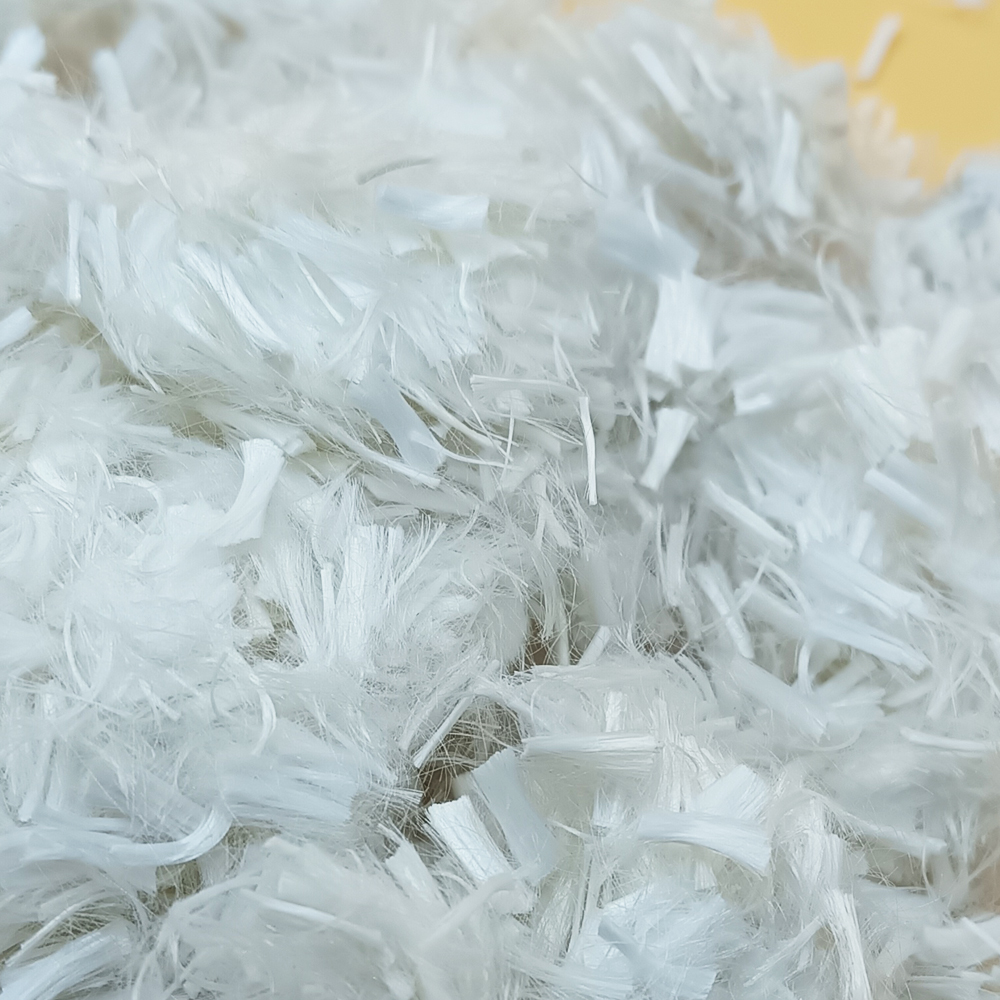

One of the most innovative uses of polymer in highway construction is the use of continuous filament for driveways. Continuous filament is a type of polymer that is extruded in a continuous length, making it ideal for creating seamless surfaces. This technology allows for the creation of smooth, durable driveways that are resistant to cracking and settling.

Continuous filament driveways offer several advantages over traditional driveway materials like concrete and asphalt. One of the main benefits is their durability. Continuous filament driveways are less prone to cracking and settling, resulting in a longer lifespan and reduced maintenance costs. This makes them an attractive option for homeowners looking for a low-maintenance driveway solution.

In addition to their durability, continuous filament driveways are also aesthetically pleasing. The seamless surface creates a clean and modern look that can enhance the curb appeal of a home. This makes them a popular choice for homeowners who want a driveway that not only performs well but also looks great.

Overall, the use of polymer for highway construction, particularly in the form of continuous filament driveways, offers a range of benefits. From increased durability and longevity to environmental sustainability and cost-effectiveness, polymer is proving to be a valuable material for modern road projects. As technology continues to advance, we can expect to see even more innovative uses of polymer in highway construction, further improving the quality and efficiency of our transportation infrastructure.