Table of Contents

Benefits of Using Seamless Steel Pipe Boiler Tubes in Oil and Gas Industry

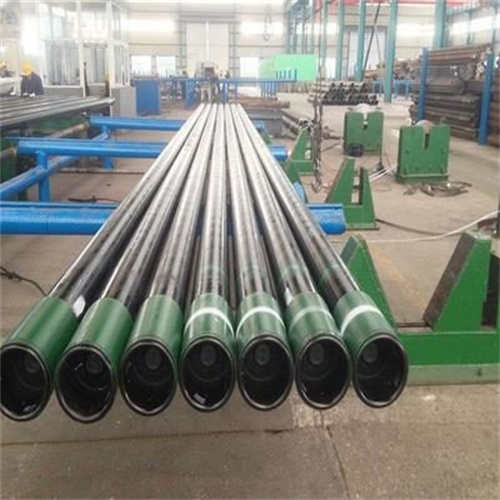

The oil and gas industry relies heavily on the use of seamless steel pipe boiler tubes to transport fluids and gases at high temperatures and pressures. These tubes are essential for the safe and efficient operation of oil and gas facilities, as they provide a reliable means of transferring heat and energy from one location to another. One of the most commonly used materials for seamless steel pipe boiler tubes in the oil and gas industry is St 35.8, which is a standard grade according to DIN 17175.

Seamless steel pipe boiler tubes offer a number of benefits that make them ideal for use in the oil and gas industry. One of the key advantages of seamless steel pipe boiler tubes is their high strength and durability. These tubes are able to withstand extreme temperatures and pressures without deforming or breaking, making them a reliable choice for Transporting fluids and gases in harsh operating conditions.

In addition to their strength and durability, seamless steel pipe boiler tubes also offer excellent corrosion resistance. This is particularly important in the oil and gas industry, where exposure to corrosive substances can cause damage to traditional piping materials. By using seamless steel pipe boiler tubes made from materials like St 35.8, companies can ensure that their pipelines remain free from corrosion and maintain their integrity over time.

Another benefit of using seamless steel pipe boiler tubes in the oil and gas industry is their ability to provide efficient heat transfer. These tubes are designed to maximize the transfer of heat from one location to another, which is essential for processes like heating and cooling in oil and gas facilities. By using seamless steel pipe boiler tubes, companies can ensure that their operations run smoothly and efficiently, without any loss of energy or heat.

Seamless steel pipe boiler tubes are also easy to install and maintain, which can help companies save time and money on their operations. These tubes can be quickly and easily connected to existing piping systems, reducing downtime and minimizing the need for costly repairs or replacements. Additionally, seamless steel pipe boiler tubes require minimal maintenance, as they are resistant to corrosion and wear, making them a cost-effective choice for companies in the oil and gas industry.

Overall, seamless steel pipe boiler tubes made from materials like St 35.8 offer a number of benefits for companies in the oil and gas industry. From their high strength and durability to their excellent corrosion resistance and efficient heat transfer capabilities, these tubes are an essential component of oil and gas facilities. By using seamless steel pipe boiler tubes, companies can ensure the safe and efficient operation of their operations, while also saving time and money on maintenance and repairs.

https://www.youtube.com/watch?v=Td4fDAePFrw