Inhoudsopgave

**Optimizing Production Efficiency in a Patch Cord Factory**

Optimizing Production Efficiency in a Patch Cord Factory

In the fast-paced world of technology, patch Cords play a vital role in ensuring seamless communication and data transfer. With the increasing demand for high-quality connectivity solutions, it becomes imperative for patch cord factories to optimize their production efficiency. This article aims to explore various strategies and techniques that can be employed to enhance productivity in a patch cord factory, ultimately leading to improved customer satisfaction and profitability.

One of the key factors in optimizing production efficiency is streamlining the manufacturing process. Implementing lean manufacturing principles can help eliminate waste and reduce production time. By analyzing the entire production cycle, identifying bottlenecks, and implementing process improvements, a patch cord factory can significantly enhance its overall efficiency. This can be achieved by adopting practices such as just-in-time inventory management, reducing setup and changeover times, and implementing visual management techniques to ensure smooth workflow and minimal downtime.

Another crucial aspect in improving production efficiency is investing in state-of-the-art machinery and equipment. By upgrading to advanced machinery, a patch cord factory can ensure faster and more accurate production. Automated machines can significantly reduce the need for manual labor, minimize human error, and enhance overall productivity. Furthermore, investing in cutting-edge testing and quality control equipment can help identify defects and ensure that only high-quality patch cords are shipped to customers.

Furthermore, optimizing the layout of the production floor can have a substantial impact on efficiency. By strategically organizing workstations, materials, and equipment, a patch cord factory can minimize unnecessary movement and optimize workflow. This can be achieved by implementing lean layout principles, such as grouping similar processes together, reducing the distance traveled by workers and materials, and ensuring a smooth and logical flow from one stage of production to another.

Efficient production planning and scheduling are also crucial elements in optimizing production efficiency. By implementing robust planning and scheduling systems, a patch cord factory can ensure that resources, including manpower and raw materials, are allocated effectively. This can help prevent production bottlenecks, minimize idle time, and improve overall productivity. Additionally, leveraging technology, such as enterprise resource planning (ERP) systems, can enable real-time tracking of production progress, inventory Levels, and customer orders, facilitating timely decision-making and ensuring customer satisfaction.

Employee training and development should not be overlooked when aiming to optimize production efficiency. Providing comprehensive training programs to employees can enhance their skills and knowledge, leading to improved productivity. Moreover, fostering a culture of continuous improvement and empowering employees to contribute their ideas and suggestions can result in innovative solutions and process enhancements. By nurturing a motivated and engaged workforce, a patch cord factory can create an Environment that fosters productivity and efficiency.

In conclusion, optimizing production efficiency in a patch

**Understanding the Quality and Pricing of Cat7 Crossover Cables from a Chinese Factory**

Understanding the Quality and Pricing of Cat7 Crossover Cables from a Chinese Factory

| Number | Commodity Name |

| 1 | Communication Cable |

In today’s rapidly evolving technological landscape, reliable and efficient network connectivity is a necessity for businesses and individuals alike. As the demand for high-speed internet connections continues to grow, the role of networking cables becomes increasingly crucial. Among the various types of cables available in the market, Cat7 crossover cables hold a prominent position due to their exceptional performance and versatility.

When it comes to sourcing Cat7 crossover cables, one option that stands out is purchasing from a Chinese factory. China has established itself as a global manufacturing hub, known for its production capabilities and competitive pricing. This article aims to provide a comprehensive understanding of the quality and pricing aspects associated with Cat7 crossover cables from a Chinese factory.

Quality is of utmost importance when it comes to networking cables, as it directly impacts the reliability and performance of the network. Chinese factories that specialize in the production of Cat7 crossover cables adhere to stringent quality control measures to ensure that their products meet international standards. These factories employ advanced manufacturing techniques and use high-quality materials to produce cables that can handle high bandwidths and transmit data at lightning-fast speeds.

Furthermore, Chinese factories often invest in research and development to stay at the forefront of technological advancements in the networking industry. This commitment to innovation allows them to continuously improve the quality of their products and meet the evolving demands of customers.

In terms of pricing, Chinese factories have a competitive edge due to their cost-effective manufacturing processes. The availability of skilled labor and access to abundant raw materials contribute to lower production costs, allowing Chinese factories to offer Cat7 crossover cables at affordable prices without compromising on quality. This cost advantage makes Chinese factories an attractive option for businesses and individuals looking for reliable networking solutions without breaking the bank.

When considering purchasing Cat7 crossover cables from a Chinese factory, it is essential to conduct thorough research and due diligence. Look for reputable manufacturers with a proven track record of delivering high-quality products. It is also advisable to seek certifications and accreditations that validate the quality standards followed by the factory.

Additionally, it is recommended to compare prices from different Chinese factories to ensure that you are getting the best value for your investment. While price is an important factor, it should not be the sole determinant in your decision-making process. Consider the reputation, experience, and customer reviews of the factory to make an informed choice.

| Serial Number | Name |

| 1 | patch cable |

In conclusion, understanding the quality and pricing aspects of Cat7 crossover cables from a Chinese factory is crucial when it comes to making an informed purchasing decision. Chinese factories offer a compelling combination of high-quality products and competitive pricing, making them a viable option for individuals

**Exploring the Benefits and Features of Patch Cable Crossover in Chinese Factories**

Exploring the Benefits and Features of Patch Cable Crossover in Chinese Factories

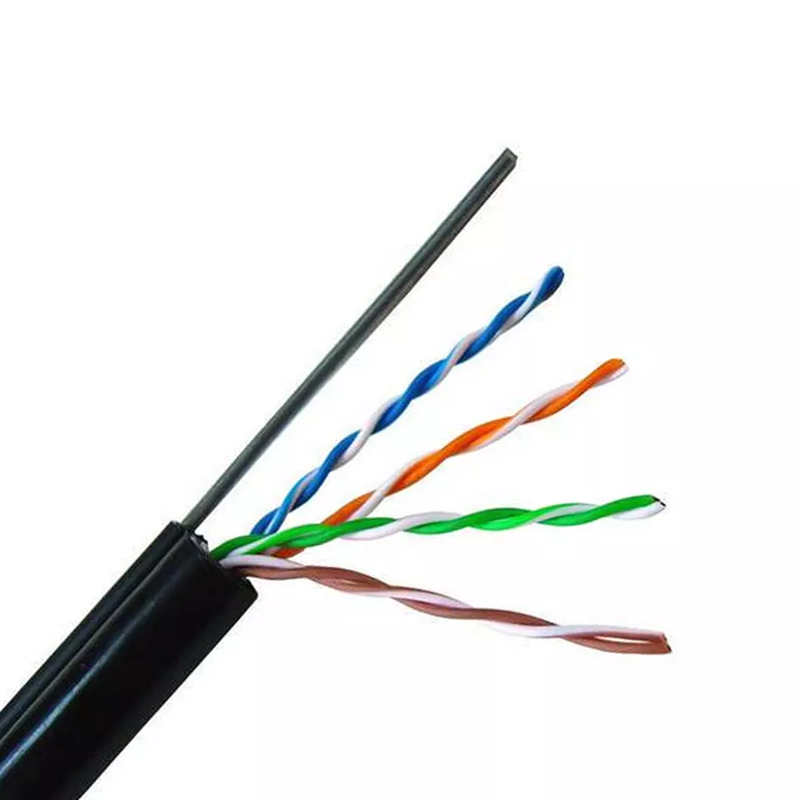

Patch cables are an essential component of any network infrastructure, connecting devices such as computers, routers, and Switches. They come in various types, and one type that has gained popularity is the patch cable crossover. In this article, we will delve into the benefits and features of patch cable crossover produced in Chinese factories.

Patch cable crossovers, also known as Cat7 crossover cables, are designed specifically for connecting devices that have the same type of ports, such as two computers or two switches. Unlike regular patch cables, crossover cables have a unique wiring configuration that allows for the exchange of data between devices. This eliminates the need for additional networking equipment, such as switches or hubs, when connecting devices directly.

One of the primary benefits of patch cable crossovers produced in Chinese factories is their high quality. Chinese manufacturers have invested heavily in state-of-the-art production facilities and employ skilled technicians who adhere to strict quality control measures. This ensures that the patch cable crossovers produced meet international standards and provide reliable and efficient data transmission.

Another advantage of patch cable crossovers from Chinese factories is their competitive pricing. Due to the large-scale production capabilities of these factories, they can offer patch cable crossovers at affordable prices without compromising on quality. This makes them a cost-effective solution for businesses and individuals looking to enhance their network connectivity without breaking the bank.

In addition to their quality and affordability, patch cable crossovers from Chinese factories also boast a range of features that make them a preferred choice for many users. These cables are typically constructed with high-quality materials, such as Copper conductors and durable insulation, ensuring a stable and interference-free connection. They also support high data transfer rates, making them suitable for demanding applications that require fast and reliable data transmission.

Furthermore, patch cable crossovers produced in Chinese factories are available in various lengths, allowing users to select the cable that best suits their specific networking needs. Whether it’s a short cable for connecting devices in close proximity or a longer cable for spanning greater distances, Chinese factories offer a wide range of options to cater to different requirements.

To summarize, patch cable crossovers produced in Chinese factories offer a host of benefits and features that make them an excellent choice for enhancing network connectivity. Their high quality, competitive pricing, and reliable performance make them a popular option for businesses and individuals alike. Whether you’re setting up a new network or expanding an existing one, consider exploring the offerings of Chinese patch cable crossover factories for a reliable and cost-effective solution.

In conclusion, patch cable crossovers from Chinese factories provide the necessary tools for efficient data transmission