Inhoudsopgave

Benefits of Using Liquid Stripping Resistance Agents in Manufacturing Processes

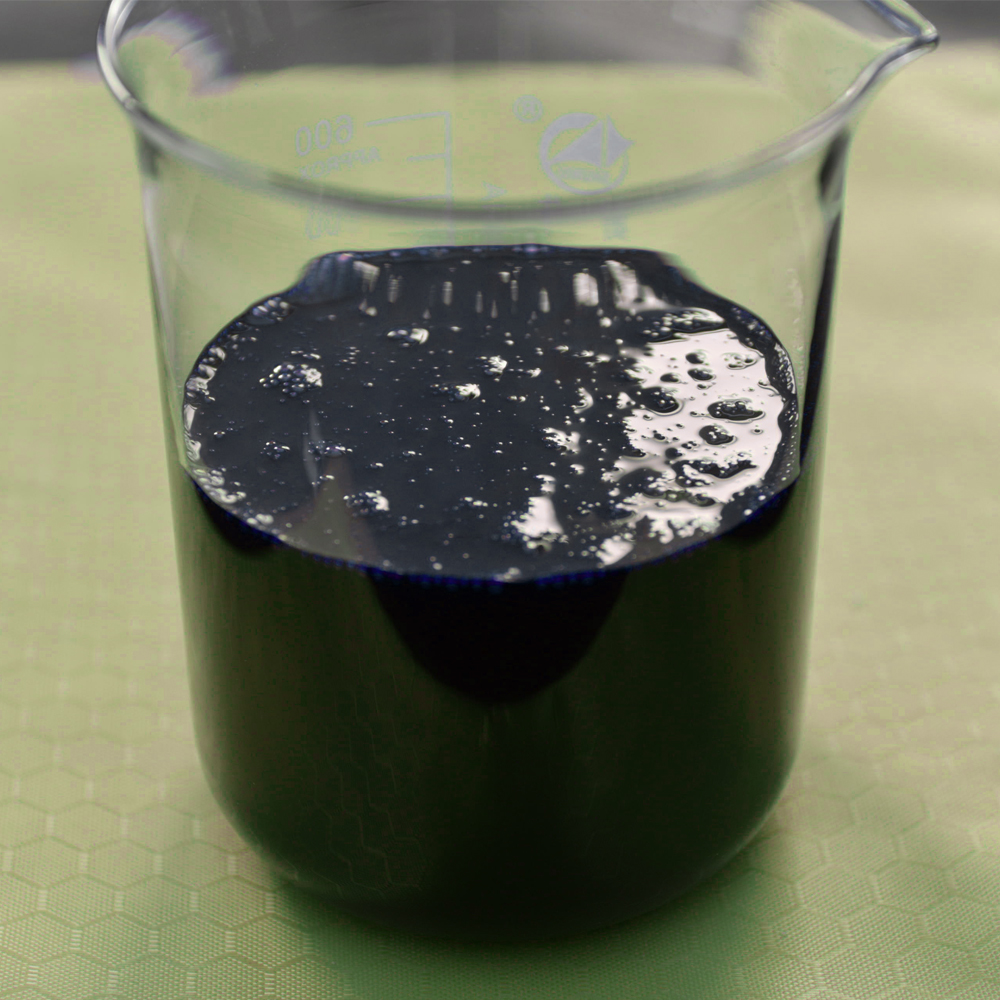

Liquid stripping resistance agents play a crucial role in various manufacturing processes by providing a protective barrier against the stripping or removal of coatings, Paints, or other materials. These agents are designed to prevent the adhesion of stripping agents to the surface, making it easier to remove the unwanted material without damaging the underlying substrate. In this article, we will explore the benefits of using liquid stripping resistance agents in manufacturing processes.

One of the key advantages of using liquid stripping resistance agents is their ability to protect delicate surfaces from damage during the stripping process. By creating a barrier between the surface and the stripping agent, these agents help to prevent scratches, dents, or other forms of damage that can occur when removing coatings or paints. This is particularly important in industries where precision and quality are paramount, such as the automotive or aerospace sectors.

Additionally, liquid stripping resistance agents can help to improve the efficiency of the stripping process by reducing the time and effort required to remove coatings or paints. By preventing the stripping agent from adhering to the surface, these agents make it easier to remove the unwanted material, saving both time and labor costs. This can result in significant cost savings for manufacturers, especially in high-volume production environments.

Another benefit of using liquid stripping resistance agents is their versatility and compatibility with a wide range of materials and surfaces. These agents can be applied to various substrates, including metals, plastics, and composites, making them suitable for use in a variety of manufacturing processes. Whether you are stripping paint from a metal surface or removing a protective coating from a plastic component, liquid stripping resistance agents can help to simplify the process and ensure a high-quality finish.

Furthermore, liquid stripping resistance agents are easy to apply and can be customized to meet the specific requirements of different manufacturing processes. Whether you need a fast-drying agent for quick turnaround times or a high-temperature resistant agent for use in extreme conditions, there are options available to suit your needs. This flexibility makes liquid stripping resistance agents a valuable tool for manufacturers looking to streamline their production processes and improve overall efficiency.

| Number | Item |

| 1 | Liquid bonding agent Additive |

In conclusion, liquid stripping resistance agents offer a range of benefits for manufacturers looking to protect delicate surfaces, improve efficiency, and enhance the quality of their products. By creating a protective barrier between the surface and the stripping agent, these agents help to prevent damage and simplify the stripping process. With their versatility, compatibility, and ease of application, liquid stripping resistance agents are a valuable addition to any manufacturing process. Whether you are working in the automotive, aerospace, or any other industry, consider incorporating liquid stripping resistance agents into your production processes to experience the benefits firsthand.