Inhoudsopgave

Reduced Energy Consumption

Warm mix bituminous modifiers have gained popularity in recent years due to their numerous cost benefits associated with their use in asphalt production. One of the key advantages of using warm mix modifiers is the reduced energy consumption during the production process. This reduction in energy consumption not only leads to cost savings for asphalt producers but also has positive environmental implications.

Traditional hot mix asphalt production requires high temperatures to heat the bitumen and aggregate materials to the necessary Levels for mixing. This process consumes a significant amount of energy, primarily in the form of fuel to heat the materials. In contrast, warm mix modifiers allow for the production of asphalt at lower temperatures, typically between 50-100 degrees Fahrenheit lower than traditional hot mix asphalt. This lower temperature requirement translates to reduced energy consumption during the production process.

By using warm mix modifiers, asphalt producers can achieve substantial energy savings, leading to lower operating costs. The reduced energy consumption not only benefits the bottom line of asphalt producers but also contributes to a more sustainable and environmentally friendly production process. Lower energy consumption means reduced greenhouse gas emissions and a smaller carbon footprint, aligning with the growing emphasis on sustainability in the construction industry.

In addition to the direct cost savings associated with reduced energy consumption, the use of warm mix modifiers can also Lead to savings in equipment maintenance and repair costs. The lower production temperatures required by warm mix modifiers result in less wear and tear on equipment, extending the lifespan of machinery such as mixers, pavers, and trucks. This reduction in maintenance and repair costs further contributes to the overall cost benefits of using warm mix modifiers in asphalt production.

Furthermore, the use of warm mix modifiers can also result in improved workability and compaction of asphalt mixtures, leading to potential savings in labor costs. The lower production temperatures allow for longer workability times, giving workers more time to properly place and compact the asphalt mixture. This improved workability can result in a more uniform and durable pavement, reducing the need for costly repairs and maintenance in the future.

Overall, the cost benefits associated with using warm mix bituminous modifiers in asphalt production are significant. From reduced energy consumption and lower operating costs to savings in equipment maintenance and repair, the financial advantages of incorporating warm mix modifiers into asphalt production are clear. Additionally, the environmental benefits of reduced energy consumption and lower greenhouse gas emissions further highlight the value of using warm mix modifiers in the construction industry.

As the demand for sustainable and cost-effective construction practices continues to grow, warm mix bituminous modifiers offer a compelling solution for asphalt producers looking to improve their bottom line while reducing their environmental impact. By embracing this innovative technology, asphalt producers can reap the financial and environmental benefits of using warm mix modifiers in asphalt production.

Extended Pavement Lifespan

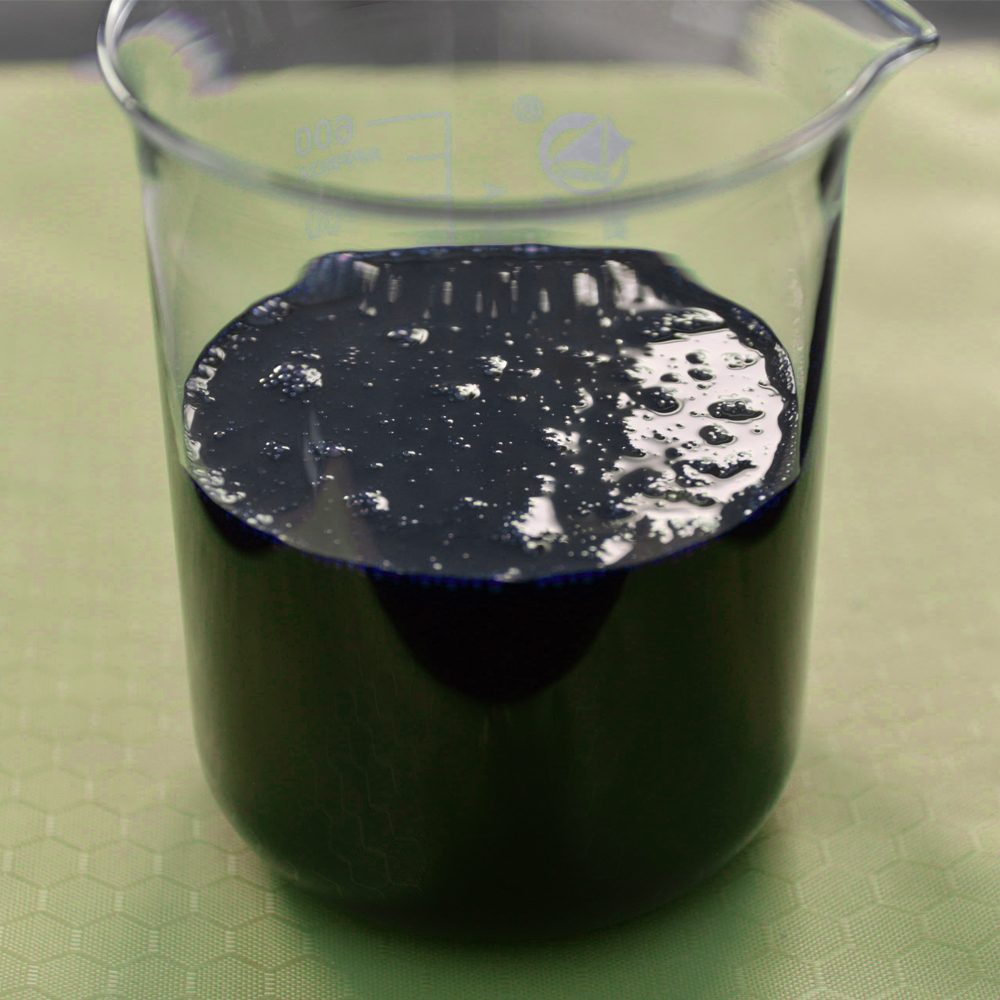

Warm mix bituminous modifiers have become increasingly popular in the asphalt production industry due to their numerous cost benefits. These modifiers are additives that are mixed with bitumen to lower the production temperature of asphalt, resulting in reduced energy consumption and lower production costs. In addition to these immediate cost savings, warm mix bituminous modifiers also offer long-term benefits that can help extend the lifespan of pavements.

One of the key cost benefits associated with using warm mix bituminous modifiers is the reduction in energy consumption during the production process. Traditional hot mix asphalt production requires high temperatures to heat the bitumen and aggregate, which can be energy-intensive and costly. By using warm mix modifiers, the production temperature can be lowered by as much as 50-100 degrees Fahrenheit, resulting in significant energy savings. This not only reduces production costs but also helps to lower greenhouse gas emissions, making warm mix asphalt a more environmentally friendly option.

| Number | Product |

| 1 | warm mix asphalt processing agents |

Another cost benefit of using warm mix bituminous modifiers is the potential for reduced maintenance and repair costs over the lifespan of the pavement. The lower production temperature of warm mix asphalt can result in improved workability and compaction, leading to a more durable and longer-lasting pavement. This can help to reduce the frequency of repairs and maintenance, saving money in the long run. Additionally, the improved performance of warm mix asphalt can help to minimize rutting, cracking, and other forms of pavement distress, further extending the lifespan of the pavement and reducing the need for costly repairs.

In addition to the cost benefits associated with reduced energy consumption and maintenance costs, warm mix bituminous modifiers can also offer savings in terms of transportation and handling. The lower production temperature of warm mix asphalt can make it easier to transport and handle, reducing the risk of material segregation and improving overall quality control. This can help to minimize waste and ensure that the asphalt meets specifications, leading to cost savings and improved performance on the job site.

Overall, the cost benefits associated with using warm mix bituminous modifiers in asphalt production are significant and can help to make this technology a cost-effective option for pavement construction. By reducing energy consumption, lowering maintenance costs, and improving workability and performance, warm mix asphalt can offer long-term savings that outweigh the initial investment in modifiers. As the industry continues to embrace sustainable and cost-effective practices, warm mix bituminous modifiers are likely to play an increasingly important role in the future of asphalt production.

In conclusion, the cost benefits associated with using warm mix bituminous modifiers in asphalt production are clear. From reduced energy consumption and lower maintenance costs to improved workability and performance, warm mix asphalt offers a cost-effective and sustainable option for pavement construction. By taking advantage of these benefits, contractors and agencies can save money, reduce environmental impact, and extend the lifespan of pavements, making warm mix bituminous modifiers a valuable tool in the industry.