Table of Contents

The Process of Manufacturing Mesh Welded Brake Pads Steel Plates

Mesh welded brake pads steel plates are an essential component in the automotive industry, as they play a crucial role in ensuring the Safety and performance of vehicles. These steel plates are used in brake pads to provide the necessary friction and heat resistance required for effective braking. In this article, we will explore the process of manufacturing mesh welded brake pads steel plates in a factory setting.

The first step in the manufacturing process is the selection of high-quality raw materials. The steel used in the production of brake pads steel plates must meet strict quality standards to ensure durability and performance. Once the raw materials are sourced, they are carefully inspected for any defects or impurities that could affect the final product.

After the raw materials have been inspected and approved, they are then cut into the desired shape and size using precision cutting machines. This step is crucial in ensuring that the steel plates are uniform in size and shape, which is essential for proper functioning in brake pads.

Once the steel plates have been cut to size, they are then welded together to create a mesh pattern. This mesh pattern provides the necessary strength and stability required for brake pads to withstand the high temperatures and pressures generated during braking. The welding process is carried out by skilled technicians using advanced Welding Equipment to ensure a strong and durable bond between the steel plates.

After the welding process is complete, the mesh welded brake pads steel plates undergo a series of quality control checks to ensure that they meet the required specifications. This includes testing the strength, durability, and heat resistance of the steel plates to ensure that they will perform effectively in brake pads.

Once the quality control checks have been completed, the steel plates are then coated with a special heat-resistant material to further enhance their performance. This coating helps to protect the steel plates from corrosion and wear, ensuring a longer lifespan for the brake pads.

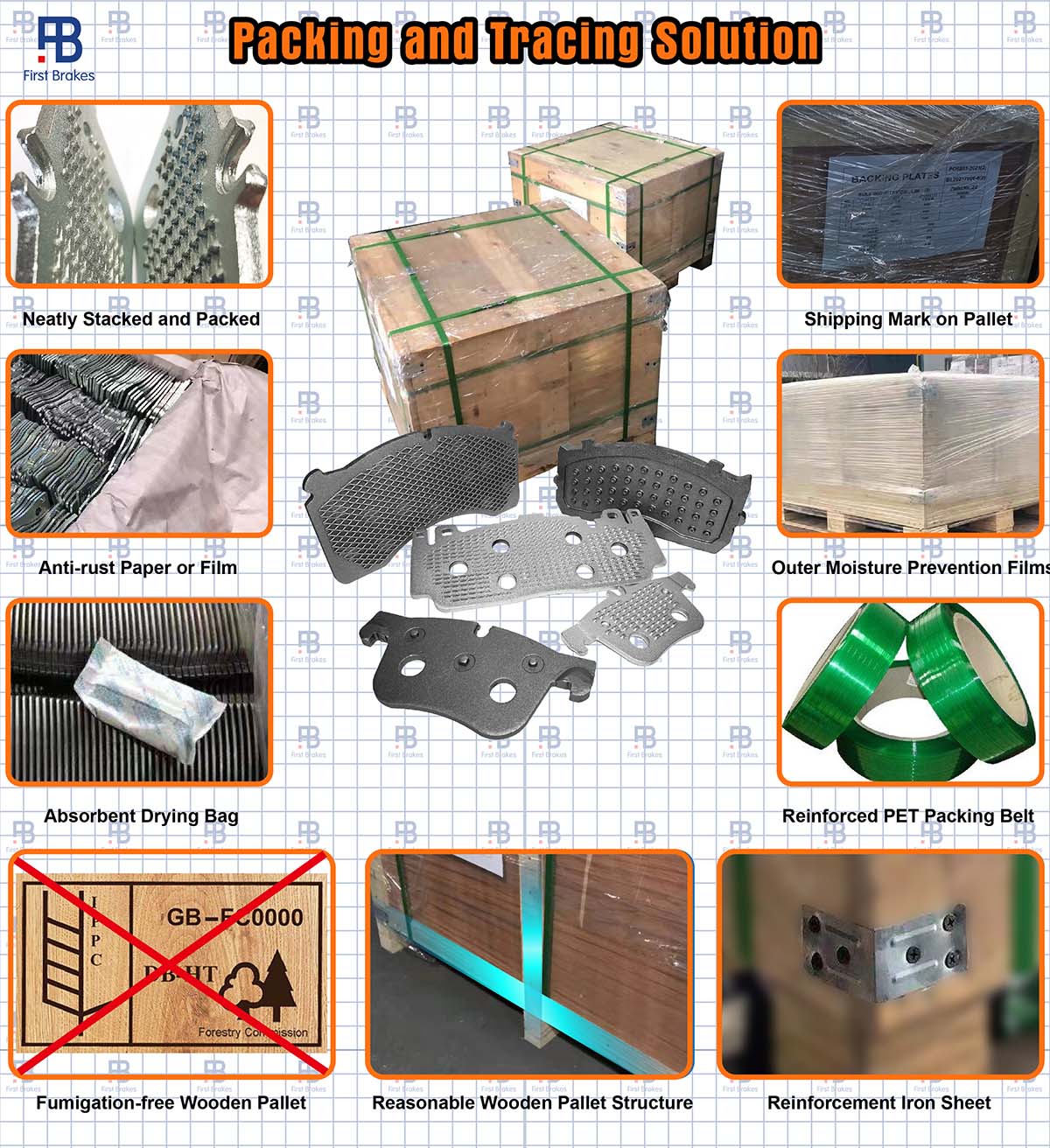

Finally, the mesh welded brake pads steel plates are packaged and shipped to automotive manufacturers for use in the production of brake pads. These steel plates play a critical role in ensuring the safety and performance of vehicles on the road, making them an essential component in the automotive industry.

In conclusion, the process of manufacturing mesh welded brake pads steel plates is a complex and precise operation that requires skilled technicians and advanced equipment. By following strict quality control measures and using high-quality raw materials, manufacturers can produce steel plates that meet the stringent requirements of the automotive industry. These steel plates play a crucial role in ensuring the safety and performance of vehicles, making them an indispensable component in the production of brake pads.