Table of Contents

How to Properly Maintain and Clean Brake Pads in a Steel Plate Making Factory

Brake pads are an essential component in any steel plate making factory, as they play a crucial role in ensuring the Safety and efficiency of the machinery. Proper maintenance and cleaning of brake pads are essential to ensure their longevity and effectiveness. In this article, we will discuss some tips on how to properly maintain and clean brake pads in a steel plate making factory.

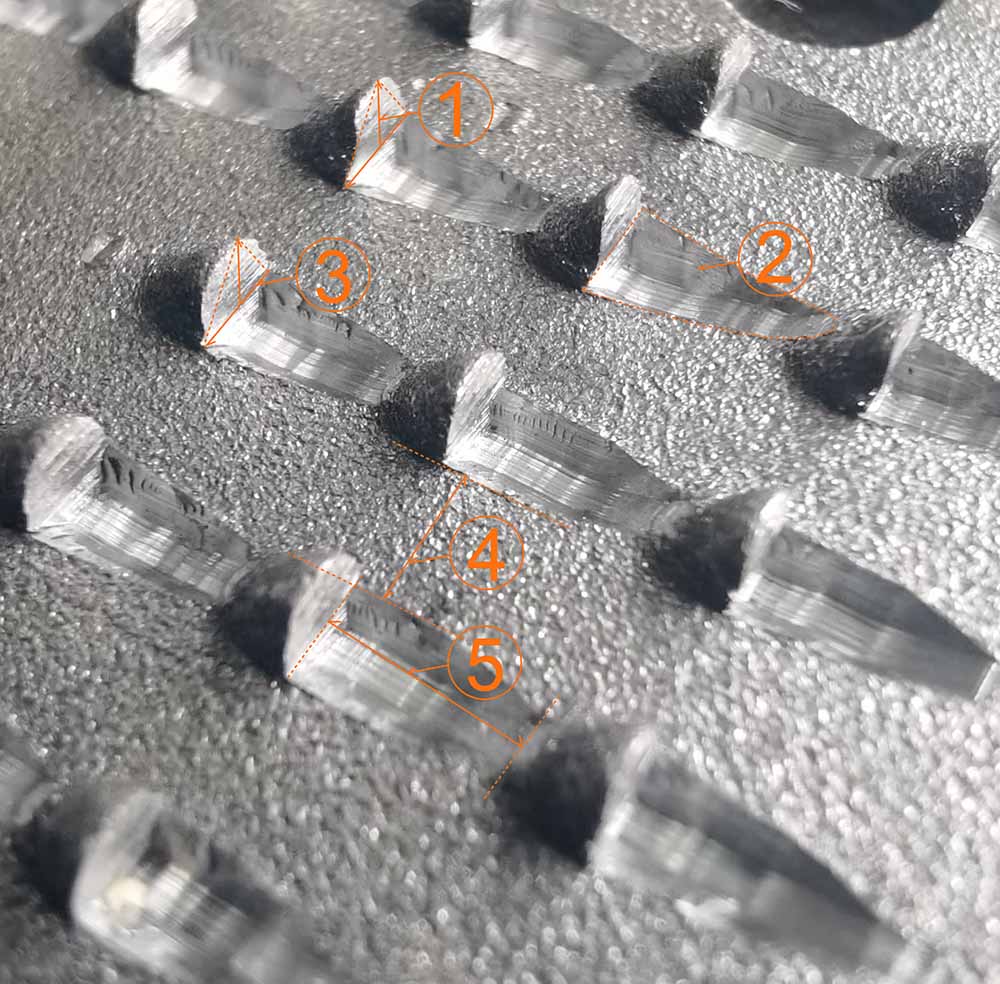

One of the most important aspects of maintaining brake pads is to regularly inspect them for wear and tear. Over time, brake pads can become worn Down due to constant use, which can affect their performance. It is important to check the thickness of the brake pads regularly and replace them if they are worn beyond the recommended thickness. This will help prevent any accidents or malfunctions that may occur due to worn-out brake pads.

In addition to regular inspections, it is also important to clean brake pads regularly to remove any dirt, debris, or contaminants that may have accumulated on them. This can be done using a mild detergent and water solution, along with a soft brush or Cloth to gently scrub the surface of the brake pads. It is important to avoid using harsh Chemicals or abrasive materials, as this can damage the brake pads and reduce their effectiveness.

Another important aspect of maintaining brake pads is to ensure that they are properly lubricated. Lubrication helps reduce friction between the brake pads and the Brake Calipers, which can help improve the performance and longevity of the brake pads. It is important to use a high-quality lubricant that is specifically designed for brake pads, and to apply it according to the manufacturer’s instructions.

In addition to regular maintenance and cleaning, it is also important to ensure that the brake pads are properly adjusted and aligned. Improper alignment can cause uneven wear on the brake pads, which can affect their performance and longevity. It is important to check the alignment of the brake pads regularly and make any necessary adjustments to ensure that they are properly aligned.

Proper storage of brake pads is also important to ensure their longevity and effectiveness. Brake pads should be stored in a cool, dry place away from direct sunlight and moisture. They should also be stored in a clean and organized manner to prevent any damage or contamination.

In conclusion, proper maintenance and cleaning of brake pads are essential to ensure their longevity and effectiveness in a steel plate making factory. By regularly inspecting, cleaning, lubricating, and aligning brake pads, you can help prevent accidents, malfunctions, and downtime in your factory. Remember to follow the manufacturer’s instructions and recommendations for maintaining and cleaning brake pads, and to store them properly to ensure their longevity. By taking these steps, you can help ensure the safety and efficiency of your machinery and operations.