Table of Contents

Benefits of Using High Quality Seamless ASTM A192 Carbon Steel Boiler Tube

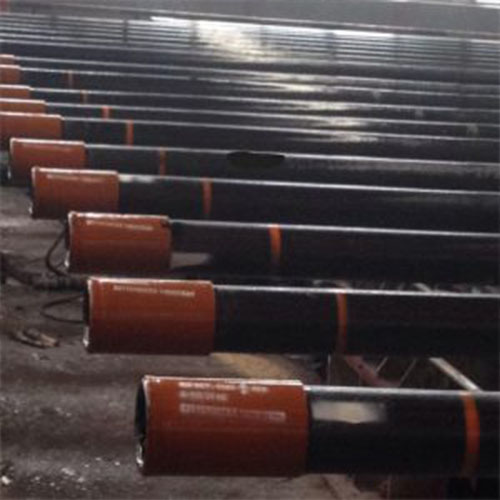

High Quality Seamless ASTM A192 Carbon Steel Boiler Tube Carbon Steel Pipe

When it comes to choosing the right materials for boiler tubes, quality is of utmost importance. High-quality seamless ASTM A192 carbon steel boiler tubes are a popular choice for many industries due to their durability, strength, and resistance to high temperatures. In this article, we will explore the benefits of using high-quality seamless ASTM A192 carbon steel boiler tubes in various applications.

One of the key benefits of using high-quality seamless ASTM A192 carbon steel boiler tubes is their superior strength and durability. These tubes are made from high-quality carbon steel, which is known for its excellent tensile strength and resistance to corrosion. This makes them ideal for use in high-pressure and high-temperature applications, such as in Boilers and Heat Exchangers.

In addition to their strength and durability, high-quality seamless ASTM A192 carbon steel boiler tubes are also known for their excellent thermal conductivity. This means that they can efficiently transfer heat from one place to another, making them ideal for use in heating systems and industrial processes that require precise temperature control.

Furthermore, high-quality seamless ASTM A192 carbon steel boiler tubes are easy to install and maintain. Their seamless design eliminates the need for welding, which can weaken the structure of the tubes and increase the risk of leaks. This makes them a cost-effective and reliable choice for many industries.

Another benefit of using high-quality seamless ASTM A192 carbon steel boiler tubes is their versatility. These tubes can be used in a wide range of applications, from power generation to chemical processing. Their ability to withstand high temperatures and pressures makes them a popular choice for industries that require reliable and efficient heat transfer solutions.

Moreover, high-quality seamless ASTM A192 carbon steel boiler tubes are environmentally friendly. Carbon steel is a recyclable material, which means that these tubes can be reused or repurposed at the end of their service life. This makes them a sustainable choice for industries that are looking to reduce their environmental impact.

In conclusion, high-quality seamless ASTM A192 carbon steel boiler tubes offer a wide range of benefits for industries that require reliable and efficient heat transfer solutions. Their superior strength, durability, thermal conductivity, and versatility make them an ideal choice for a variety of applications. Additionally, their ease of installation and maintenance, as well as their environmental friendliness, make them a cost-effective and sustainable option for many industries. Whether you are in the power generation, chemical processing, or heating industry, high-quality seamless ASTM A192 carbon steel boiler tubes are a reliable and efficient choice for your heat transfer needs.

How to Choose the Right ASTM A192 Carbon Steel Boiler Tube for Your Project

When it comes to choosing the right ASTM A192 carbon steel boiler tube for your project, quality is key. High-quality seamless carbon Steel Pipes are essential for ensuring the efficiency and longevity of your boiler system. ASTM A192 carbon steel boiler tubes are specifically designed for high-pressure applications in power plants, refineries, and other industrial settings. These tubes are known for their exceptional strength, durability, and resistance to corrosion, making them an ideal choice for demanding boiler applications.

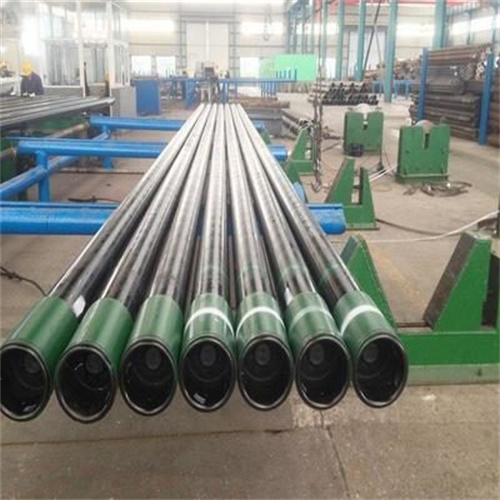

One of the most important factors to consider when selecting an ASTM A192 carbon steel boiler tube is the manufacturing process. Seamless tubes are preferred over welded tubes for boiler applications because they offer superior strength and reliability. Seamless tubes are made by piercing a solid billet of steel to create a hollow tube, while welded tubes are made by welding together multiple pieces of steel. Seamless tubes have a uniform Grain structure and are less prone to defects, making them more reliable for high-pressure applications.

In addition to the manufacturing process, it is important to consider the quality of the steel used in the production of ASTM A192 carbon steel boiler tubes. High-quality carbon steel with a low carbon content is preferred for boiler applications because it offers excellent strength and toughness. Low-carbon steel is less prone to brittleness and cracking, which can occur under high temperatures and pressures. It is also important to ensure that the steel used in the production of the boiler tube meets the specifications outlined in ASTM A192, which sets the standards for seamless carbon steel boiler tubes.

Another important consideration when choosing an ASTM A192 carbon steel boiler tube is the size and dimensions of the tube. The size of the tube will depend on the specific requirements of your boiler system, including the pressure and temperature ratings, as well as the flow rate of the steam or hot water. It is important to select a tube that is the right size for your application to ensure optimal performance and efficiency.

When selecting an ASTM A192 carbon steel boiler tube, it is also important to consider the surface finish of the tube. A smooth surface finish is essential for ensuring proper heat transfer and minimizing the risk of corrosion. Tubes with a rough or uneven surface can create hot spots and reduce the efficiency of the boiler system. It is important to choose a tube with a smooth surface finish that meets the specifications outlined in ASTM A192.

In conclusion, choosing the right ASTM A192 carbon steel boiler tube is essential for ensuring the efficiency and longevity of your boiler system. High-quality seamless carbon steel tubes that are manufactured using high-quality steel and meet the specifications outlined in ASTM A192 are the best choice for demanding boiler applications. By considering factors such as the manufacturing process, steel quality, size and dimensions, and surface finish, you can select a boiler tube that will meet your specific requirements and deliver reliable performance for years to come.

Maintenance Tips for Extending the Lifespan of Carbon Steel Boiler Tubes

Carbon steel boiler tubes are an essential component in many industrial processes, providing a means of transferring heat from a source to a destination. These tubes are subjected to high temperatures and pressures, making them susceptible to wear and corrosion over time. To ensure the longevity and efficiency of your carbon steel boiler tubes, it is crucial to implement proper maintenance practices. In this article, we will discuss some tips for extending the lifespan of your ASTM A192 carbon steel boiler tubes.

One of the most important maintenance tasks for carbon steel boiler tubes is regular cleaning. Over time, these tubes can accumulate debris, scale, and other contaminants that can impede heat transfer and Lead to corrosion. To prevent this buildup, it is recommended to clean the tubes regularly using a suitable cleaning solution and a soft brush. This will help to remove any deposits and ensure that the tubes remain free from obstructions.

In addition to cleaning, it is also important to inspect the carbon steel boiler tubes regularly for signs of wear and corrosion. Look for any signs of pitting, cracking, or rusting on the surface of the tubes, as these can indicate potential issues that need to be addressed. If any damage is found, it is important to repair or replace the affected tubes as soon as possible to prevent further deterioration.

Another important maintenance tip for extending the lifespan of carbon steel boiler tubes is to monitor the water chemistry in the boiler system. Water quality plays a crucial role in the corrosion resistance of the tubes, so it is important to test the water regularly and make any necessary adjustments to ensure that it meets the recommended standards. This can help to prevent corrosion and prolong the lifespan of the tubes.

In addition to regular cleaning, inspection, and water chemistry monitoring, it is also important to protect the carbon steel boiler tubes from external factors that can contribute to corrosion. This includes ensuring that the tubes are properly insulated to prevent heat loss and condensation, as well as protecting them from exposure to harsh Chemicals or environmental conditions that can accelerate corrosion.

By implementing these maintenance tips, you can help to extend the lifespan of your ASTM A192 carbon steel boiler tubes and ensure that they continue to operate efficiently for years to come. Proper maintenance practices are essential for preserving the integrity of the tubes and preventing costly repairs or replacements Down the line. With regular cleaning, inspection, water chemistry monitoring, and protection from external factors, you can help to maximize the lifespan of your carbon steel boiler tubes and ensure that they continue to perform at their best.