Table of Contents

Benefits of Warm Mix Asphalt in Cold Weather Conditions

Warm Mix Asphalt (WMA) has gained popularity in recent years as a more sustainable and environmentally friendly alternative to traditional hot mix asphalt. One of the key benefits of WMA is its ability to be used in cold weather conditions, thanks to the use of low-temperature asphalt additives. These additives help reduce the viscosity of the asphalt binder, allowing it to be mixed and compacted at lower temperatures than conventional hot mix asphalt.

One of the main advantages of using WMA in cold weather conditions is the reduced energy consumption and greenhouse gas emissions associated with the production and placement of the asphalt. By lowering the mixing and compaction temperatures, WMA requires less energy to produce and can be laid at lower temperatures, reducing fuel consumption and emissions from the construction process. This not only helps reduce the environmental impact of road construction but also lowers costs for contractors and agencies.

| Serial Number | Commodity Name |

| 1 | warm mix Bitumen modifiers |

In addition to its environmental benefits, WMA offers improved workability and compaction compared to traditional hot mix asphalt in cold weather conditions. The lower mixing temperatures of WMA result in a longer working time, allowing contractors more flexibility in placing and compacting the asphalt. This can be particularly advantageous in colder climates where the window for paving operations may be limited due to temperature constraints.

Furthermore, the use of low-temperature asphalt additives in WMA can help improve the overall performance and durability of the pavement. By reducing the thermal stress on the asphalt binder during mixing and compaction, WMA can result in a more uniform and consistent pavement structure. This can Lead to reduced cracking and rutting, extending the service life of the pavement and reducing maintenance costs over time.

Another benefit of using WMA in cold weather conditions is its ability to be recycled and reused. Because WMA can be produced at lower temperatures, it is easier to incorporate reclaimed asphalt pavement (RAP) into the mix. This not only reduces the demand for virgin materials but also helps divert waste from landfills, making WMA a more sustainable option for road construction.

Overall, the use of warm mix asphalt with low-temperature additives offers a number of benefits for road construction in cold weather conditions. From reduced energy consumption and emissions to improved workability and durability, WMA provides a more sustainable and cost-effective alternative to traditional hot mix asphalt. By incorporating WMA into their projects, contractors and agencies can not only reduce their environmental impact but also improve the performance and longevity of their pavements. As the demand for sustainable and resilient infrastructure continues to grow, WMA with low-temperature additives is poised to play a key role in meeting these challenges head-on.

Comparing Different Low-Temperature Asphalt Additives for Improved Performance

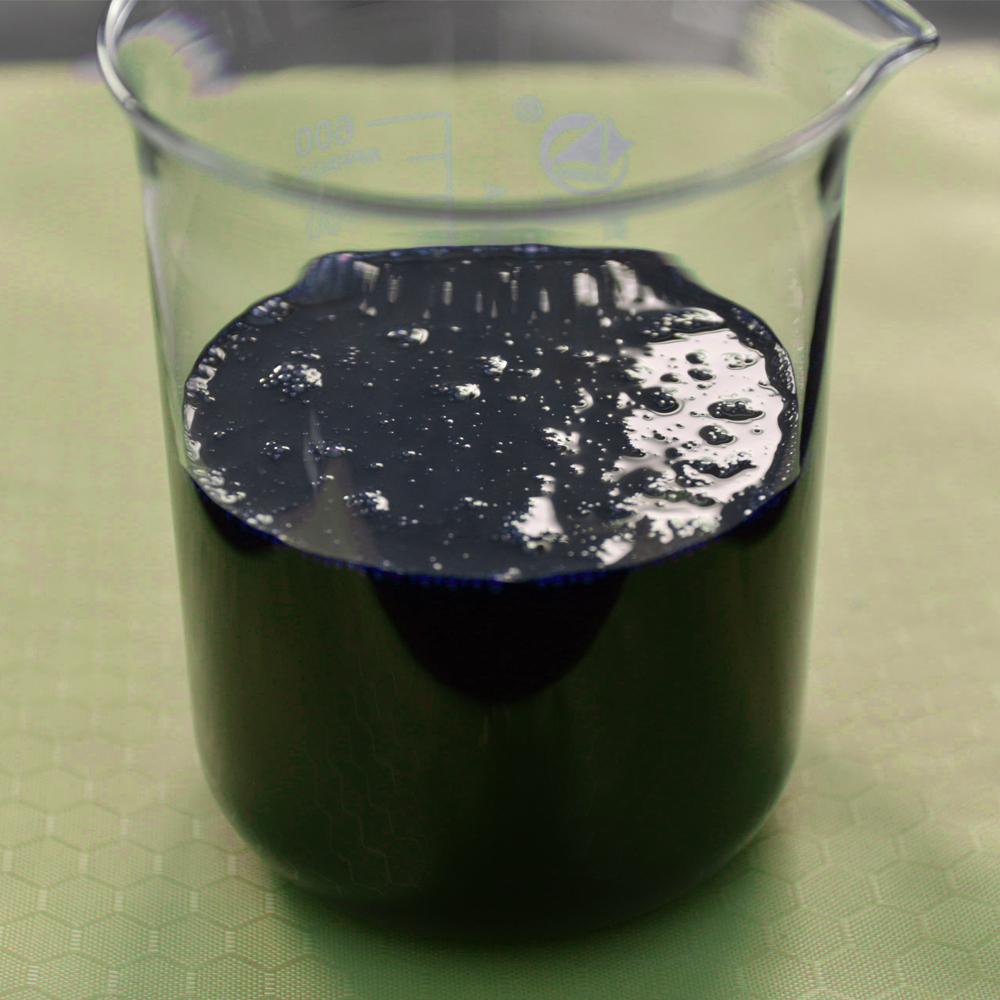

Warm mix asphalt (WMA) has gained popularity in recent years as a more sustainable and environmentally friendly alternative to traditional hot mix asphalt (HMA). One of the key benefits of WMA is its ability to be produced and placed at lower temperatures, reducing energy consumption and greenhouse gas emissions. To achieve these lower production temperatures, various additives are used to modify the asphalt binder and improve workability. In this article, we will compare different low-temperature asphalt additives and their impact on the performance of WMA.

One common type of low-temperature asphalt additive is organic Wax, which acts as a lubricant to reduce the viscosity of the asphalt binder at lower temperatures. This allows for easier mixing and compaction of the asphalt mixture, resulting in improved workability and reduced energy consumption during production. Organic wax additives have been shown to enhance the performance of WMA by improving its resistance to rutting and cracking, as well as increasing its durability and longevity.

Another type of low-temperature asphalt additive is chemical warm mix additives, which work by chemically modifying the asphalt binder to reduce its viscosity and improve workability at lower temperatures. These additives can be classified into two main categories: surfactants and chemical foaming agents. Surfactants reduce the surface tension of the asphalt binder, allowing for better coating of the aggregate particles and improved adhesion between the binder and aggregate. Chemical foaming agents, on the other hand, generate gas bubbles within the asphalt binder, creating a foamed asphalt mixture that is easier to work with and compact.

In recent years, nanoclay additives have emerged as a promising alternative for improving the performance of WMA. Nanoclay particles have a high surface area and can absorb a significant amount of asphalt binder, leading to improved dispersion and adhesion between the binder and aggregate. This results in a more homogeneous asphalt mixture with enhanced mechanical properties, such as increased stiffness and resistance to rutting and cracking. Nanoclay additives have also been shown to reduce the aging of the asphalt binder and improve its resistance to moisture damage.

In addition to organic wax, chemical warm mix additives, and nanoclay, other low-temperature asphalt additives include anti-stripping agents, rejuvenators, and polymers. Anti-stripping agents improve the adhesion between the asphalt binder and aggregate by reducing the moisture susceptibility of the mixture. Rejuvenators are used to restore the aging properties of recycled asphalt pavement (RAP) materials, improving their performance and durability. Polymers can be added to the asphalt binder to enhance its elasticity and resistance to deformation, resulting in a more durable and long-lasting pavement.

Overall, the choice of low-temperature asphalt additive depends on the specific requirements of the project, such as the climate conditions, traffic volume, and pavement design. By carefully selecting and incorporating the right additive into the asphalt mixture, engineers and contractors can improve the performance and longevity of WMA pavements, while also reducing energy consumption and environmental impact. As research and development in this field continue to advance, new and innovative additives are expected to further enhance the performance of WMA and pave the way for a more sustainable and resilient infrastructure.