Table of Contents

Avantages de l’utilisation de tuyaux en acier sans soudure au carbone ASTM A106 Gr B

En conclusion, les tubes en acier sans soudure au carbone ASTM A106 Gr B et les tubes en acier de précision laminés à froid ASTM A53 Gr B sont tous deux d’excellents choix pour une large gamme d’applications industrielles. En comprenant les avantages uniques de chaque matériau, les ingénieurs et les chefs de projet peuvent prendre des décisions éclairées lors de la sélection du tuyau ou du tube en acier approprié pour leurs projets.

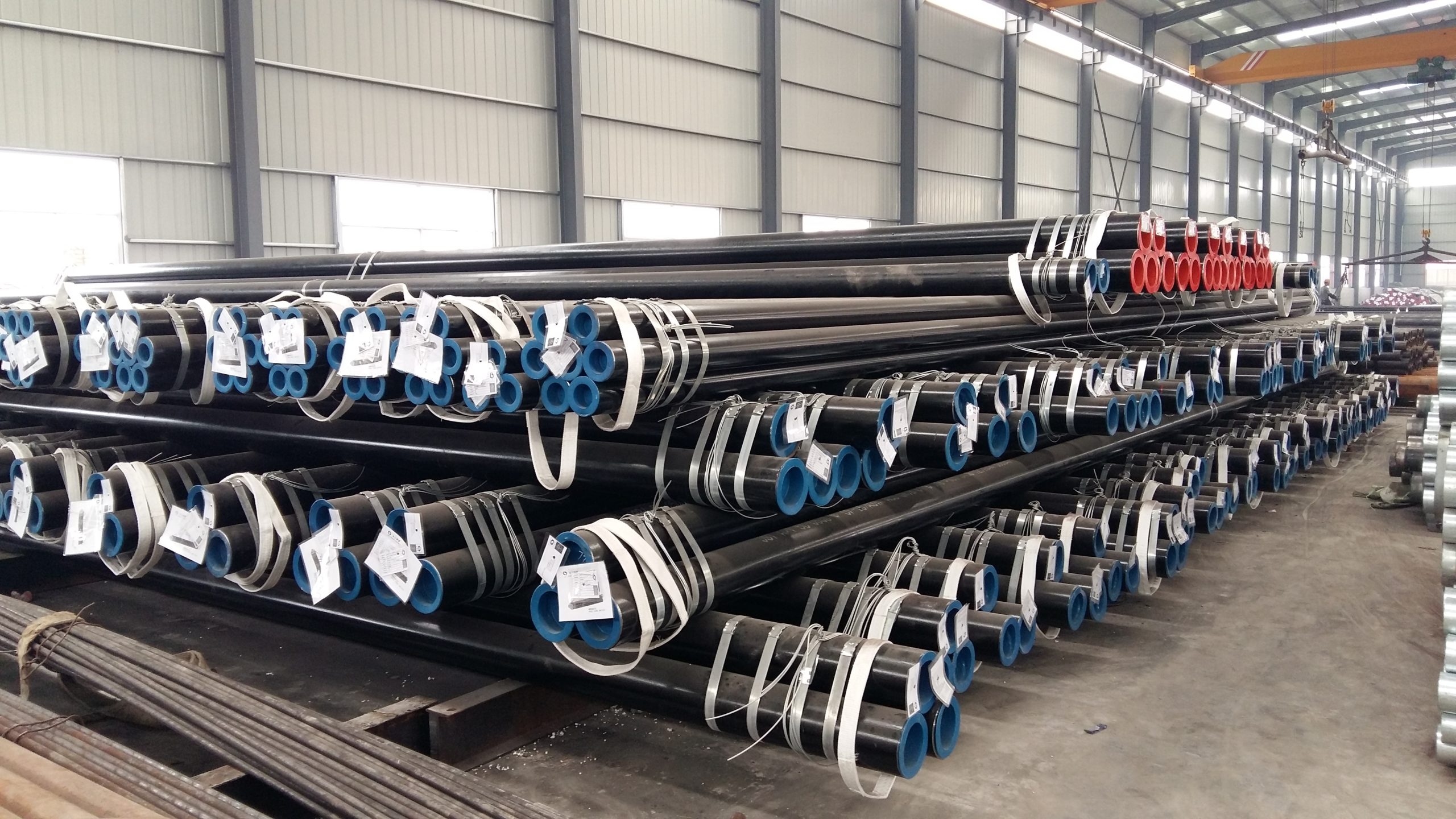

One of the main benefits of ASTM A106 Gr B carbon seamless steel pipe is its high strength and durability. This type of steel pipe is made from Carbon Steel, which is known for its excellent tensile strength and resistance to corrosion. This makes it a reliable choice for applications that require a strong and long-lasting material. Additionally, the seamless design of ASTM A106 Gr B carbon steel pipe eliminates the need for welding, reducing the risk of weak points in the structure and ensuring a smooth flow of fluids or gases.

Another advantage of ASTM A106 Gr B carbon seamless steel pipe is its versatility. This type of steel pipe can be used in a wide range of applications, including oil and gas pipelines, structural support, and machinery components. Its ability to withstand high temperatures and pressures makes it suitable for demanding environments where other materials may fail. Additionally, ASTM A106 Gr B carbon seamless steel pipe is available in various sizes and thicknesses, making it easy to find the right fit for any project.

In comparison, ASTM A53 Gr B cold rolled precision steel tubing offers its own set of benefits. This type of steel tubing is known for its precision manufacturing process, which results in a smooth and uniform surface finish. This makes it ideal for applications that require a high level of accuracy and consistency, such as automotive components, hydraulic systems, and instrumentation.

ASTM A53 Gr B cold rolled precision steel tubing is also known for its excellent dimensional accuracy and tight tolerances. This ensures that the tubing will fit perfectly in its intended application, reducing the risk of leaks or other issues. Additionally, the cold rolling process used to manufacture ASTM A53 Gr B steel tubing results in a stronger and more durable material compared to hot rolled steel.

While both ASTM A106 Gr B carbon seamless steel pipe and ASTM A53 Gr B cold rolled precision steel tubing offer unique benefits, the choice between the two ultimately depends on the specific requirements of the project. ASTM A106 Gr B carbon seamless steel pipe is best suited for applications that require high strength and durability, while ASTM A53 Gr B cold rolled precision steel tubing is ideal for projects that demand precision and dimensional accuracy.

https://www.youtube.com/watch?v=KTkCUlEf3fo

In conclusion, ASTM A106 Gr B carbon seamless steel pipe and ASTM A53 Gr B cold rolled precision steel tubing are both excellent choices for a wide range of industrial applications. By understanding the unique benefits of each material, engineers and project managers can make informed decisions when selecting the right steel pipe or tubing for their projects.