Table of Contents

Improved Durability and Longevity of Asphalt Pavements

Bitumen rheology modifiers play a crucial role in enhancing the performance of asphalt pavements. These modifiers are additives that are used to alter the rheological properties of bitumen, which is the binding agent in asphalt. By modifying the rheology of bitumen, these additives can improve the durability and longevity of asphalt pavements, making them more resistant to various forms of distress such as rutting, cracking, and fatigue.

One of the key benefits of using bitumen rheology modifiers in asphalt is the improvement in the resistance to rutting. Rutting is a common form of distress in asphalt pavements, especially in areas with high traffic volumes and heavy loads. By modifying the rheological properties of bitumen, these additives can increase the stiffness of the asphalt mix, making it more resistant to permanent deformation under traffic loads. This results in a smoother and more durable pavement surface that can withstand the stresses of heavy traffic without deforming.

In addition to improving resistance to rutting, bitumen rheology modifiers can also enhance the resistance to cracking in asphalt pavements. Cracking is another common form of distress in asphalt pavements, caused by a combination of factors such as temperature fluctuations, moisture infiltration, and traffic loading. By modifying the rheology of bitumen, these additives can improve the flexibility and elasticity of the asphalt mix, making it more resistant to cracking. This helps to prevent the formation of cracks in the pavement surface, which can Lead to water infiltration and further deterioration of the pavement structure.

| Part | Commodity Name |

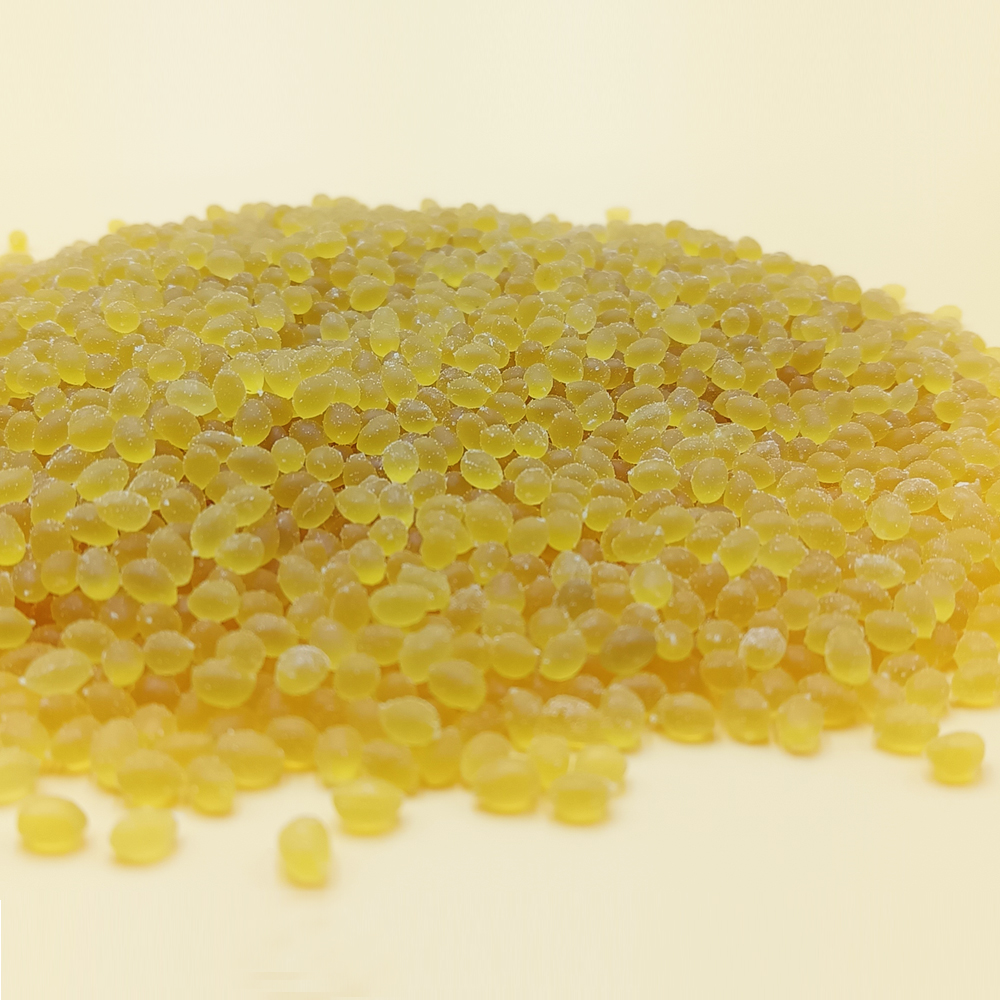

| 1 | viscosity asphalt additives |

Furthermore, bitumen rheology modifiers can also improve the resistance to fatigue cracking in asphalt pavements. Fatigue cracking is a type of distress that occurs due to repeated loading and unloading of the pavement surface, leading to the formation of cracks and eventually the failure of the pavement structure. By modifying the rheological properties of bitumen, these additives can increase the fatigue resistance of the asphalt mix, making it more durable and long-lasting. This helps to extend the service life of the pavement and reduce the need for frequent maintenance and repairs.

Overall, the use of bitumen rheology modifiers in asphalt pavements offers a wide range of benefits in terms of improved durability and longevity. These additives can enhance the resistance to rutting, cracking, and fatigue cracking, making the pavement more resilient to various forms of distress. This results in a smoother, safer, and more durable pavement surface that can withstand the rigors of heavy traffic and harsh environmental conditions. By incorporating bitumen rheology modifiers into asphalt mixes, engineers and contractors can ensure the long-term performance and sustainability of asphalt pavements, ultimately saving time, money, and resources in the maintenance and repair of road infrastructure.

Enhanced Resistance to Cracking and Rutting in Asphalt Mixtures

Bitumen rheology modifiers play a crucial role in enhancing the performance of asphalt mixtures, particularly in terms of resistance to cracking and rutting. These modifiers are additives that are used to alter the rheological properties of bitumen, which is the binder that holds the aggregate particles together in asphalt mixtures. By modifying the rheology of bitumen, these additives can improve the overall performance of asphalt pavements, making them more durable and long-lasting.

One of the key benefits of using bitumen rheology modifiers in asphalt mixtures is their ability to enhance resistance to cracking. Cracking is a common problem in asphalt pavements, particularly in regions with extreme temperature fluctuations. When asphalt pavements are subjected to repeated loading and thermal stresses, they can develop cracks that compromise their structural integrity and longevity. By incorporating rheology modifiers into the bitumen, the viscosity and elasticity of the binder can be adjusted to better withstand these stresses, reducing the likelihood of cracking.

Furthermore, bitumen rheology modifiers can also improve resistance to rutting in asphalt mixtures. Rutting is a form of permanent deformation that occurs in asphalt pavements when the material is subjected to heavy traffic loads over time. This can lead to depressions or ruts in the surface of the pavement, which not only affects the ride quality for motorists but also compromises the overall structural integrity of the pavement. By modifying the rheological properties of the bitumen, the binder can better resist the deformation caused by traffic loads, reducing the risk of rutting and extending the service life of the pavement.

In addition to enhancing resistance to cracking and rutting, bitumen rheology modifiers can also improve the overall performance of asphalt mixtures in terms of fatigue resistance. Fatigue cracking is a common form of distress in asphalt pavements, particularly in areas with high traffic volumes. By adjusting the rheological properties of the bitumen, the binder can better withstand the repeated loading and unloading cycles that occur in pavement structures, reducing the likelihood of fatigue cracking and extending the service life of the pavement.

Overall, the use of bitumen rheology modifiers in asphalt mixtures offers a range of benefits in terms of enhancing the performance and durability of pavements. By modifying the rheological properties of the bitumen, these additives can improve resistance to cracking, rutting, and fatigue, ultimately leading to longer-lasting and more sustainable pavement structures. As the demand for more durable and resilient infrastructure continues to grow, the use of bitumen rheology modifiers will play an increasingly important role in ensuring the longevity and performance of asphalt pavements.