Table of Contents

Benefits of Using Cable Wire Per Meter in Industrial Applications

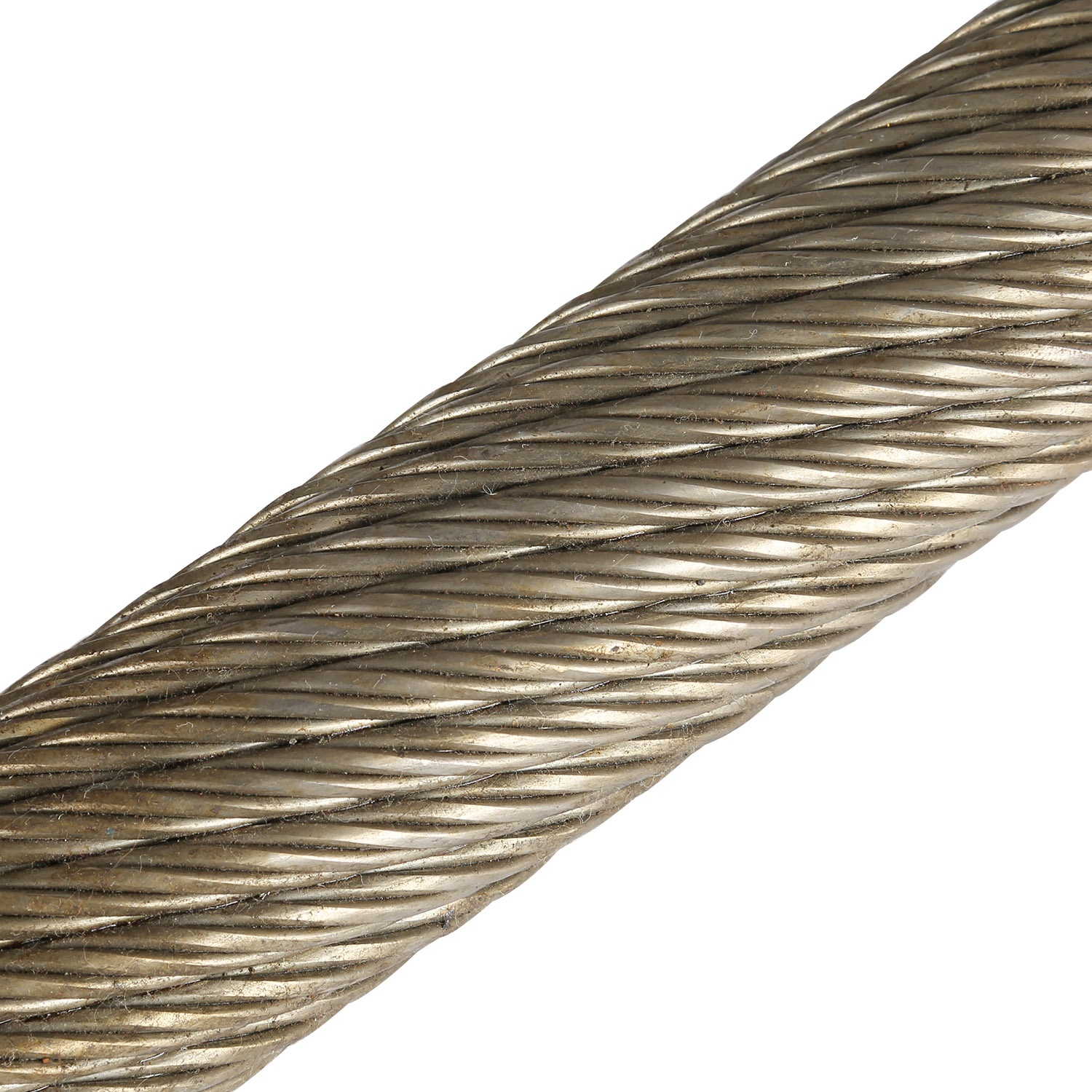

Cable wire per meter is an essential component in various industrial applications, especially in mining operations where durability and reliability are crucial. Abrasion-resistant steel wire Rope is a popular choice for these demanding environments due to its strength and ability to withstand harsh conditions. In this article, we will explore the benefits of using cable wire per meter in industrial applications, with a focus on its advantages in mining operations.

One of the primary benefits of using cable wire per meter in industrial applications is its durability. Abrasion-resistant steel wire rope is designed to withstand the wear and tear of daily use in challenging environments. This durability ensures that the wire rope can handle heavy loads and rough handling without breaking or wearing out quickly. In mining operations, where equipment is subjected to extreme conditions, having a reliable and durable cable wire per meter is essential for ensuring the Safety and efficiency of operations.

Another key benefit of using cable wire per meter in industrial applications is its strength. Abrasion-resistant steel wire rope is made from high-quality materials that provide superior strength and reliability. This strength allows the wire rope to support heavy loads and withstand the stresses of daily use without stretching or breaking. In mining operations, where equipment is often subjected to high Levels of stress and strain, having a strong and reliable cable wire per meter is essential for ensuring the safety and efficiency of operations.

In addition to its durability and strength, cable wire per meter also offers excellent resistance to abrasion. Abrasion-resistant steel wire rope is designed to withstand the friction and wear that can occur during daily use in industrial applications. This resistance to abrasion ensures that the wire rope maintains its integrity and performance over time, even in harsh environments. In mining operations, where equipment is often exposed to abrasive materials and rough handling, having a cable wire per meter that can withstand abrasion is essential for ensuring the longevity and reliability of equipment.

Furthermore, cable wire per meter is easy to install and maintain, making it a cost-effective solution for industrial applications. Abrasion-resistant steel wire rope is designed to be flexible and easy to work with, allowing for quick and efficient installation. Additionally, the low maintenance requirements of cable wire per meter make it a cost-effective option for industrial applications, as it reduces the need for frequent repairs and replacements. In mining operations, where downtime can be costly, having a cable wire per meter that is easy to install and maintain is essential for ensuring the smooth operation of equipment.

Overall, the benefits of using cable wire per meter in industrial applications, particularly in mining operations, are clear. From its durability and strength to its resistance to abrasion and ease of installation, cable wire per meter offers a reliable and cost-effective solution for demanding environments. By choosing abrasion-resistant steel wire rope for mining operations, companies can ensure the safety, efficiency, and longevity of their equipment, ultimately leading to improved productivity and profitability.

How to Choose the Right Abrasion-Resistant Steel Wire Rope for Mining Operations

Mining operations require durable and reliable equipment to ensure the safety and efficiency of the work being done. One crucial component of mining equipment is the steel wire rope used for various applications such as hoisting, hauling, and lifting heavy loads. When it comes to mining operations, abrasion-resistant steel wire rope is essential to withstand the harsh conditions and heavy wear and tear that it will be subjected to.

When choosing the right abrasion-resistant steel wire rope for mining operations, there are several factors to consider. One of the most important factors is the construction of the wire rope. The construction refers to the arrangement of wires and strands that make up the rope. In mining operations, a compacted strand construction is often preferred as it provides greater strength and durability compared to other constructions.

Another important factor to consider is the material used in the construction of the wire rope. Abrasion-resistant steel wire ropes are typically made from high-strength steel alloys that are specifically designed to withstand abrasion and wear. These alloys are heat-treated to improve their strength and durability, making them ideal for use in mining operations where heavy loads and harsh conditions are common.

In addition to the construction and material of the wire rope, the diameter of the rope is also an important consideration. The diameter of the wire rope will determine its strength and load-bearing capacity. In mining operations, it is important to choose a wire rope with a diameter that is suitable for the specific application and load requirements. Thicker ropes are generally stronger and more durable, but they may also be heavier and more difficult to handle.

When selecting an abrasion-resistant steel wire rope for mining operations, it is also important to consider the type of core used in the construction of the rope. The core provides support and stability to the strands of the wire rope, helping to maintain its shape and strength under heavy loads. In mining operations, a Fiber core is often preferred as it provides greater flexibility and resistance to crushing compared to a steel core.

Furthermore, the surface coating of the wire rope is another important factor to consider when choosing a wire rope for mining operations. Abrasion-resistant steel wire ropes are often coated with a protective layer to enhance their resistance to abrasion and wear. This coating can help to extend the life of the wire rope and reduce the risk of damage from harsh conditions in mining operations.

In conclusion, choosing the right abrasion-resistant steel wire rope for mining operations is essential to ensure the safety and efficiency of the work being done. By considering factors such as construction, material, diameter, core type, and surface coating, mining operators can select a wire rope that is durable, reliable, and able to withstand the demands of their operations. Investing in high-quality abrasion-resistant steel wire rope will ultimately Lead to improved performance, reduced downtime, and increased safety in mining operations.