Table of Contents

Benefits of Using an Automatic Cloth End Edge Cutting Machine

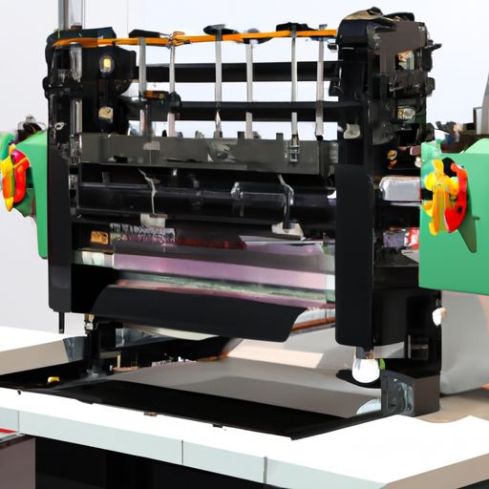

Automatic cloth end edge cutting machines are a valuable tool for any business that deals with Fabric on a regular basis. These machines offer a wide range of benefits that can help improve efficiency, accuracy, and overall productivity. In this article, we will explore some of the key advantages of using an automatic cloth end edge cutting machine.

One of the primary benefits of using an automatic cloth end edge cutting machine is the time savings it provides. These machines are designed to quickly and accurately cut fabric to the desired length, eliminating the need for manual cutting. This can significantly reduce the amount of time it takes to complete a project, allowing businesses to increase their output and meet tight deadlines more easily.

In addition to saving time, automatic cloth end edge cutting machines also help improve accuracy. These machines are programmed to cut fabric to precise measurements, ensuring that each piece is the correct size and shape. This can help reduce waste and minimize errors, leading to higher quality finished products.

Another key benefit of using an automatic cloth end edge cutting machine is the consistency it provides. Manual cutting can Lead to variations in size and shape, which can affect the overall quality of the finished product. By using an automatic cutting machine, businesses can ensure that each piece of fabric is cut to the same specifications, resulting in a more uniform and professional-looking end result.

Automatic cloth end edge cutting machines are also incredibly versatile. These machines can be used to cut a wide range of fabrics, from lightweight materials like cotton and silk to heavier fabrics like denim and canvas. This versatility makes them a valuable tool for businesses in a variety of industries, from clothing manufacturers to upholstery Shops.

In addition to their versatility, automatic cloth end edge cutting machines are also easy to use. These machines are typically equipped with user-friendly controls that allow operators to quickly and easily set the desired cutting parameters. This makes them accessible to employees of all skill Levels, helping businesses streamline their production processes and improve overall efficiency.

Finally, automatic cloth end edge cutting machines can help businesses save money in the long run. While the initial investment in a cutting machine may be significant, the time and labor savings it provides can quickly offset this cost. Additionally, by reducing waste and improving accuracy, these machines can help businesses minimize material costs and maximize their profits.

In conclusion, automatic cloth end edge cutting machines offer a wide range of benefits for businesses that work with fabric on a regular basis. From saving time and improving accuracy to providing consistency and versatility, these machines can help businesses streamline their production processes and improve overall efficiency. By investing in an automatic cutting machine, businesses can increase their output, reduce waste, and ultimately improve their bottom line.

How to Choose the Right Small Portable Fabric End Cutter for Your Needs

When it comes to choosing the right small portable fabric end cutter for your needs, there are several factors to consider. These machines are designed to cut fabric quickly and accurately, making them ideal for a variety of applications such as cutting gloves, roller blinds, curtains, and more. With so many options available on the market, it can be overwhelming to decide which one is the best fit for your specific requirements.

One of the first things to consider when choosing a small portable fabric end cutter is the type of fabric you will be cutting. Different machines are designed to handle different types of fabric, so it’s important to choose one that is compatible with the materials you will be working with. For example, if you will primarily be cutting lightweight fabrics such as cotton or silk, you may not need a machine that is as heavy-duty as one designed for cutting heavy-duty materials like denim or canvas.

Another important factor to consider is the cutting capacity of the machine. Some small portable fabric end cutters are designed for cutting only a few layers of fabric at a time, while others can handle multiple layers with ease. If you will be cutting large quantities of fabric or working with thick materials, you will want to choose a machine with a higher cutting capacity to ensure efficiency and accuracy.

In addition to cutting capacity, it’s also important to consider the cutting speed of the machine. A faster cutting speed can help you complete your projects more quickly, but it’s important to balance speed with precision. Look for a machine that offers a good balance of speed and accuracy to ensure clean, precise cuts every time.

Ease of use is another important factor to consider when choosing a small portable fabric end cutter. Look for a machine that is easy to set up and operate, with intuitive controls and clear instructions. Some machines also offer additional features such as automatic blade sharpening or adjustable cutting angles, which can make your cutting tasks even easier.

Portability is also a key consideration when choosing a small portable fabric end cutter. Look for a machine that is lightweight and easy to transport, with a compact design that won’t take up too much space in your workspace. Some machines also offer battery-powered operation, making them even more portable and versatile.

Finally, consider the overall quality and durability of the machine. Look for a small portable fabric end cutter that is made from high-quality materials and built to last. A machine that is durable and reliable will provide years of use and help you complete your projects with ease.

In conclusion, choosing the right small portable fabric end cutter for your needs requires careful consideration of factors such as cutting capacity, cutting speed, ease of use, portability, and overall quality. By taking the time to research and compare different machines, you can find the perfect tool to help you cut fabric quickly and accurately for a variety of applications.