Table of Contents

Benefits of Implementing an Intelligent Operation and Maintenance Management Platform for Steel Structure Buildings

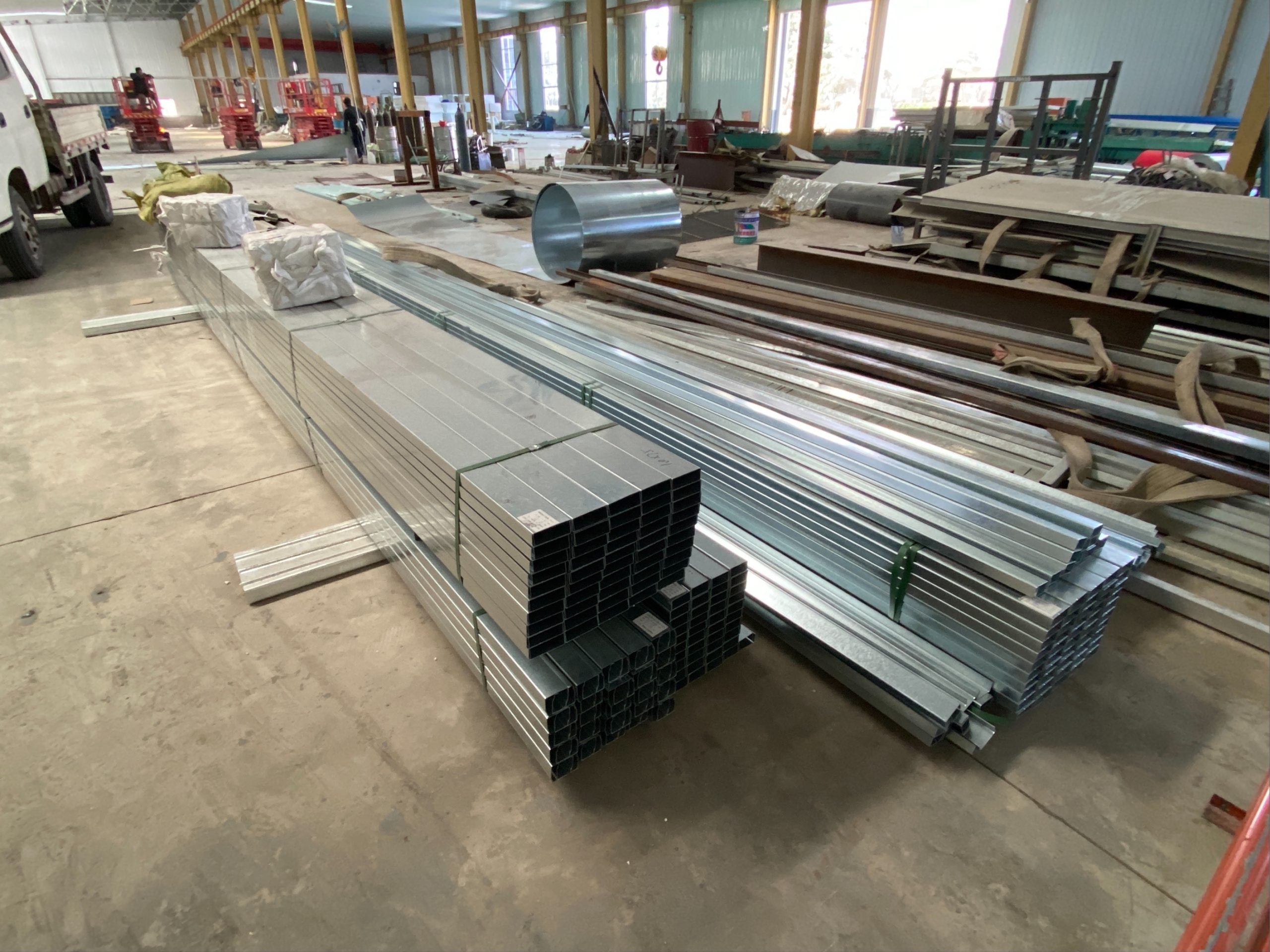

Steel structure buildings are becoming increasingly popular due to their durability, cost-effectiveness, and sustainability. However, like any other type of building, Steel Structures require regular maintenance to ensure their longevity and Safety. Traditional operation and maintenance management methods can be time-consuming and inefficient, leading to increased costs and potential safety risks. This is where intelligent operation and maintenance management platforms come into play.

These platforms leverage cutting-edge technology such as artificial intelligence, Internet of Things (IoT), and big data analytics to streamline the operation and maintenance processes of steel structure buildings. By integrating these technologies, building owners and managers can monitor the health and performance of their structures in real-time, identify potential issues before they escalate, and optimize maintenance schedules to minimize downtime and costs.

One of the key benefits of implementing an intelligent operation and maintenance management platform for steel structure buildings is improved efficiency. Traditional maintenance practices often rely on manual inspections and reactive repairs, which can be time-consuming and prone to human error. With an intelligent platform, Sensors and monitoring devices can be installed throughout the building to collect data on various parameters such as temperature, humidity, structural integrity, and energy consumption. This data is then analyzed in real-time to detect anomalies and predict potential failures, allowing maintenance teams to proactively address issues before they become critical.

In addition to improving efficiency, intelligent operation and maintenance management platforms also enhance safety. By continuously monitoring the structural health of the building, these platforms can alert building owners and managers to potential safety hazards such as corrosion, cracks, or structural instability. This early warning system enables timely intervention to prevent accidents and ensure the safety of occupants and assets within the building.

Furthermore, intelligent platforms enable predictive maintenance, which can significantly reduce maintenance costs and extend the lifespan of steel structure buildings. By analyzing historical data and performance trends, these platforms can predict when components are likely to fail and schedule maintenance activities accordingly. This proactive approach not only minimizes downtime and disruption but also helps to optimize maintenance budgets by focusing resources on critical areas that require immediate attention.

Another benefit of intelligent operation and maintenance management platforms is the ability to optimize energy efficiency. By monitoring energy consumption patterns and identifying areas of inefficiency, building owners can make informed decisions to reduce energy waste and lower operating costs. For example, the platform may recommend adjusting HVAC settings, upgrading insulation, or implementing energy-saving technologies to improve the building’s overall energy performance.

In conclusion, the technical innovation of intelligent operation and maintenance management platforms offers numerous benefits for steel structure buildings. From improved efficiency and safety to predictive maintenance and energy optimization, these platforms empower building owners and managers to proactively manage their assets and maximize their return on investment. By leveraging the power of technology, steel structure buildings can achieve higher Levels of performance, sustainability, and resilience in the face of evolving challenges and demands.

Case Studies: Successful Implementation of Technical Innovations in Steel Structure Building Maintenance

Steel structure buildings are a common sight in modern cities, with their sleek and sturdy designs making them a popular choice for various commercial and industrial applications. However, like any other type of building, steel structures require regular maintenance to ensure their longevity and safety. In recent years, there has been a growing trend towards the use of intelligent operation and maintenance management platforms to streamline the maintenance process and improve efficiency.

One such platform that has gained popularity in the industry is the intelligent operation and maintenance management platform developed specifically for steel structure buildings. This platform utilizes cutting-edge technology such as artificial intelligence, Internet of Things (IoT), and big data analytics to monitor the condition of the building in real-time, predict potential issues before they occur, and automate maintenance tasks.

By integrating sensors and monitoring devices throughout the building, the platform is able to collect data on various parameters such as temperature, humidity, structural integrity, and energy consumption. This data is then analyzed using advanced algorithms to identify patterns and trends that can help predict when maintenance is needed. For example, if a sensor detects a sudden increase in temperature in a certain area of the building, it could indicate a potential electrical issue that needs to be addressed before it escalates into a more serious problem.

In addition to predictive maintenance, the platform also offers features such as remote monitoring and control, asset management, and energy optimization. Building managers can access the platform through a user-friendly interface on their computer or mobile device, allowing them to monitor the building’s performance in real-time, schedule maintenance tasks, and adjust settings to optimize energy efficiency.

One of the key benefits of using an intelligent operation and maintenance management platform for steel structure buildings is the ability to reduce downtime and minimize costly repairs. By proactively addressing maintenance issues before they become critical, building owners can avoid unexpected breakdowns and disruptions to their operations. This not only saves money in the long run but also helps to ensure the safety of occupants and the integrity of the building.

Several case studies have demonstrated the successful implementation of this technology in real-world scenarios. For example, a large manufacturing facility that implemented the intelligent operation and maintenance management platform Saw a significant reduction in maintenance costs and downtime. By monitoring the condition of their equipment in real-time and scheduling maintenance tasks based on data-driven insights, the facility was able to prevent several potential breakdowns and extend the lifespan of their machinery.

Another case study involved a commercial office building that used the platform to optimize energy consumption and reduce utility costs. By analyzing data on energy usage patterns and identifying areas of inefficiency, the building managers were able to make targeted adjustments to their HVAC Systems and lighting controls, resulting in substantial savings on their energy bills.

Overall, the technical innovation of intelligent operation and maintenance management platforms for steel structure buildings represents a significant advancement in the field of building maintenance. By harnessing the power of technology to monitor, analyze, and optimize building performance, these platforms offer a cost-effective and efficient solution for ensuring the long-term sustainability of steel structures. As more buildings adopt this technology, we can expect to see improvements in safety, efficiency, and overall building performance across the industry.