Table of Contents

Benefits of Using Optimal Asphalt Production Temperature in Chinese Factories

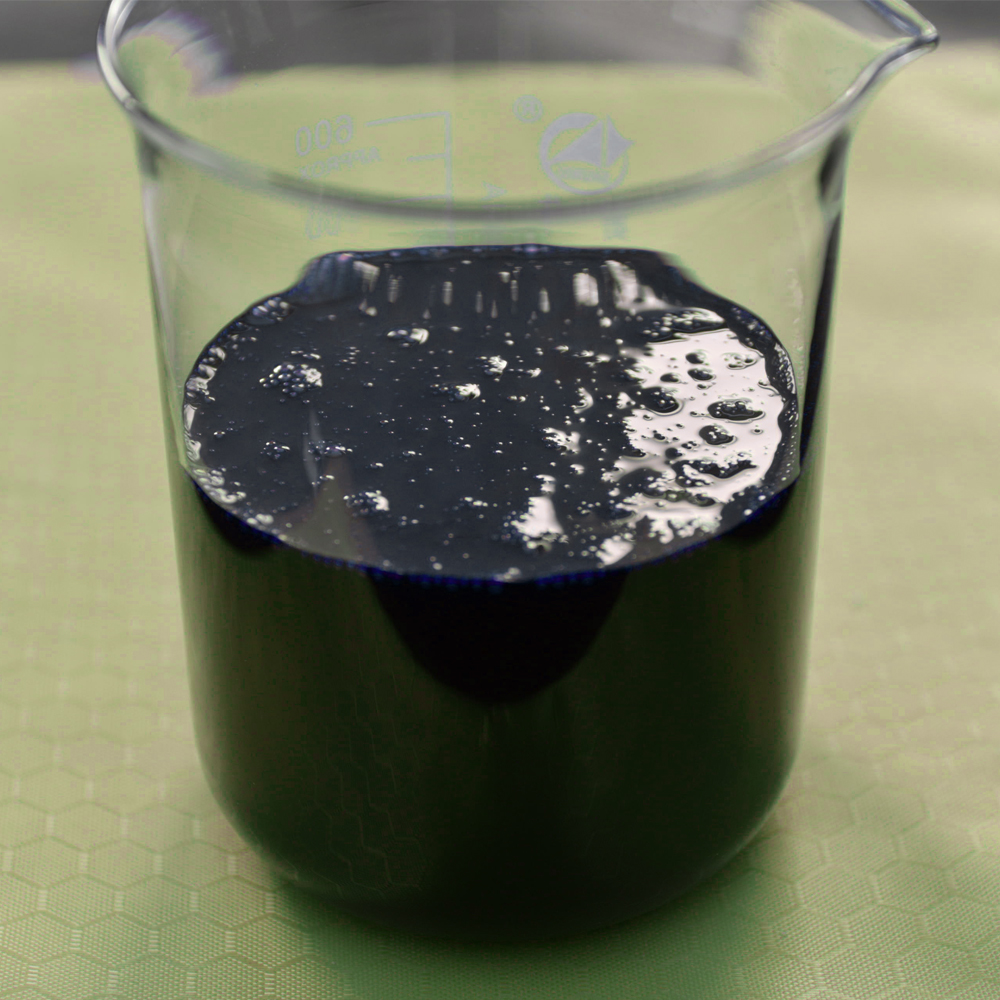

Asphalt production is a crucial process in the construction industry, as it is used to create the roads and highways that connect cities and facilitate transportation. In China, the demand for high-quality asphalt has been steadily increasing due to the country’s rapid urbanization and infrastructure development. To meet this demand, Chinese factories have been focusing on optimizing their asphalt production processes, with one key factor being the temperature at which the asphalt is produced.

The optimal temperature for asphalt production is typically between 150 and 160 degrees Celsius. This temperature range allows for the asphalt to be mixed thoroughly and evenly, resulting in a more durable and long-lasting product. Chinese factories that have implemented strict temperature control measures in their production processes have seen significant improvements in the quality of their asphalt products.

One of the main benefits of using the optimal production temperature for asphalt is improved workability. When asphalt is produced at the right temperature, it is easier to handle and spread, which reduces the risk of uneven surfaces and cracks forming in the finished product. This is especially important in China, where extreme weather conditions can put a strain on road surfaces.

In addition to improved workability, using the optimal production temperature for asphalt also results in a more consistent and uniform mix. This means that the asphalt will have a higher density and better compaction, leading to increased durability and resistance to wear and tear. Chinese factories that have adopted this approach have reported a decrease in the need for maintenance and repairs on roads and highways constructed with their asphalt products.

Furthermore, producing asphalt at the right temperature can also help reduce energy consumption and emissions. By ensuring that the asphalt is mixed efficiently and effectively, factories can minimize waste and reduce the amount of energy needed to produce each batch of asphalt. This not only helps to lower production costs but also contributes to a more sustainable and environmentally friendly manufacturing process.

| Number | Product Name |

| 1 | Bitumen Heating Agent |

Another advantage of using the optimal production temperature for asphalt is improved Safety. When asphalt is produced at the correct temperature, it is less likely to cause accidents or injuries during the construction process. Workers can handle the asphalt more easily and safely, reducing the risk of burns or other injuries that can occur when working with hot materials.

Overall, the benefits of using the optimal production temperature for asphalt in Chinese factories are clear. From improved workability and durability to reduced energy consumption and enhanced safety, optimizing the production process can Lead to higher-quality asphalt products that meet the growing demand in the construction industry. By prioritizing temperature control in their production processes, Chinese factories can continue to produce top-notch asphalt that contributes to the country’s infrastructure development and economic growth.