Table of Contents

**Understanding API Standard for Drill Pipe, Casing, and Tubing Drift for Oil Pipe**

Understanding API Standard for Drill Pipe, Casing, and Tubing Drift for Oil Pipe

In the oil and gas industry, the American Petroleum Institute (API) sets standards that ensure the quality, Safety, and efficiency of equipment used in drilling and production operations. Among these standards are those pertaining to drill pipe, casing, and tubing drift, which are essential for maintaining the integrity of oil pipes. Understanding the API standards for drill pipe, casing, and tubing drift is crucial for ensuring the proper functioning and safety of oil pipe systems.

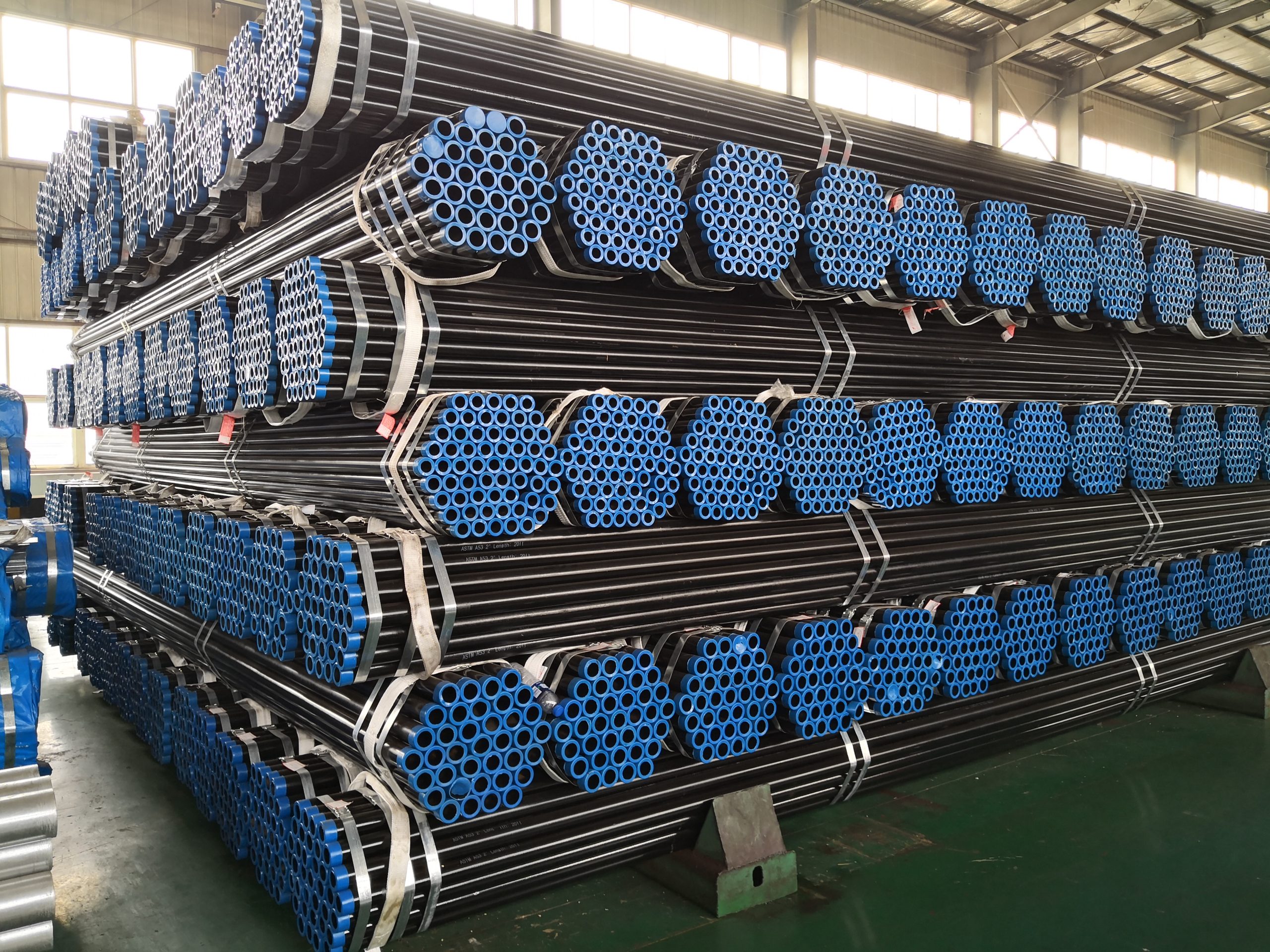

Drill pipe, casing, and tubing are integral components of oil and gas wells, serving different purposes in the drilling and production processes. Drill pipes are used to transmit drilling fluid and torque from the surface to the drilling bit, while casing provides structural support to the wellbore and protects the surrounding Environment from potential contamination. Tubing, on the other hand, is used to transport produced fluids from the well to the surface. The API standards for these components, including their drift specifications, are designed to guarantee their reliability and performance in demanding oilfield environments.

API standards for drill pipe, casing, and tubing drift define the allowable dimensions and tolerances for these critical components. The drift of a pipe refers to the minimum diameter of a tool that can pass through it without encountering any obstruction. By establishing drift specifications, API ensures that the internal diameter of drill pipe, casing, and tubing remains within acceptable limits, preventing potential issues such as blockages, restrictions, or inefficient fluid flow. Compliance with these standards is essential for maintaining the operational integrity and safety of oil pipe systems.

Furthermore, API standards for drill pipe, casing, and tubing drift also address the roundness and straightness of these components. Roundness refers to the deviation of the pipe’s cross-sectional shape from a perfect circle, while straightness pertains to the absence of significant bends or deformations along the length of the pipe. These criteria are crucial for ensuring the proper functioning of downhole tools, such as Pumps, Motors, and packers, which rely on the uniformity and consistency of the pipe’s geometry. By adhering to API standards, manufacturers and operators can minimize the risk of equipment failure and operational disruptions caused by out-of-specification pipes.

In addition to dimensional and geometric requirements, API standards for drill pipe, casing, and tubing drift also address material properties and mechanical characteristics. These specifications ensure that the pipes have the necessary strength, toughness, and corrosion resistance to withstand the harsh conditions encountered in oil and gas wells. By setting stringent material and mechanical requirements, API enhances the reliability and longevity of drill pipe, casing, and tubing, reducing the likelihood of premature failures and costly interventions in the field.

In conclusion