Table of Contents

Benefits of Using API Gas Line ERW Carbon Steel Pipe for Water Treatment Applications

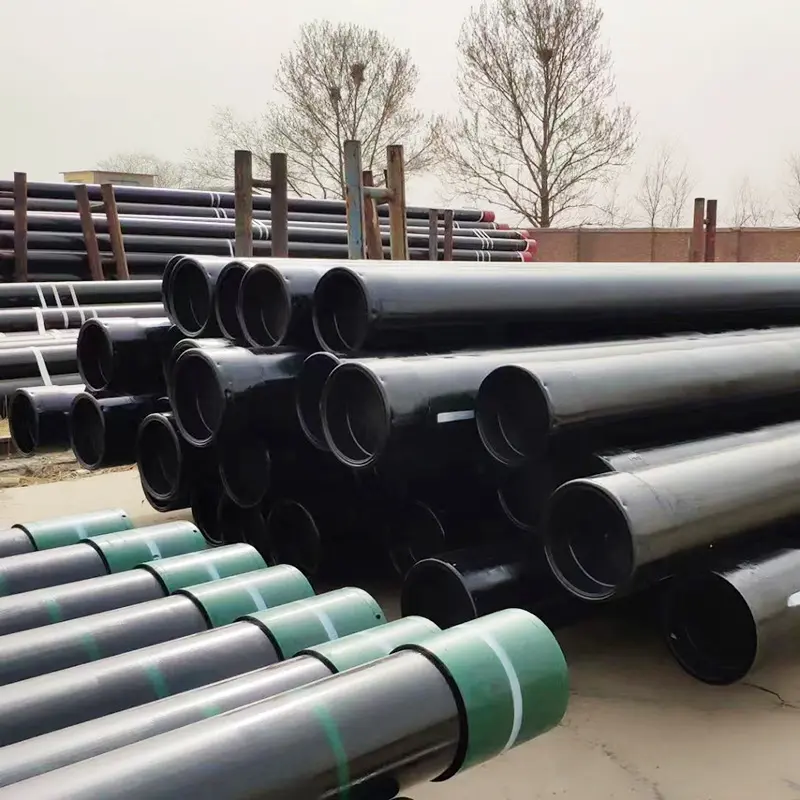

API Gas Line ERW Carbon Steel Pipe is a versatile and durable option for various applications, including water treatment. This type of pipe is known for its high strength and resistance to corrosion, making it an ideal choice for Transporting water in treatment facilities. In this article, we will explore the benefits of using API Gas Line ERW Carbon Steel Pipe for water treatment applications.

One of the key advantages of API Gas Line ERW Carbon Steel Pipe is its high strength-to-weight ratio. This means that it can withstand high pressure and heavy loads without deforming or breaking. In water treatment facilities, where pipes are often subjected to high pressure and flow rates, this strength is crucial for ensuring the safe and efficient transport of water.

Additionally, API Gas Line ERW Carbon Steel Pipe is highly resistant to corrosion, which is a common issue in water treatment applications. Corrosion can weaken pipes over time, leading to leaks and contamination of the water supply. By using API Gas Line ERW Carbon Steel Pipe, water treatment facilities can minimize the risk of corrosion-related issues and ensure the integrity of their water transport systems.

Another benefit of API Gas Line ERW Carbon Steel Pipe is its versatility. This type of pipe can be easily customized to meet the specific requirements of water treatment applications. Whether it is for casing, water treatment, UL fire protection, pile driving, drilling, or construction, API Gas Line ERW Carbon Steel Pipe can be tailored to fit the unique needs of each project.

https://www.youtube.com/watch?v=goTqY010yDAFurthermore, API Gas Line ERW Carbon Steel Pipe can be coated with galvanized or polyethylene coatings to further enhance its durability and resistance to corrosion. These coatings provide an additional layer of protection against environmental factors, ensuring the longevity of the pipe and reducing maintenance costs over time.

In addition to its physical properties, API Gas Line ERW Carbon Steel Pipe is also cost-effective compared to other materials. Its long lifespan and low maintenance requirements make it a cost-efficient choice for water treatment facilities looking to optimize their budget without compromising on quality.

Overall, API Gas Line ERW Carbon Steel Pipe offers a range of benefits for water treatment applications, including high strength, corrosion resistance, versatility, and cost-effectiveness. By choosing this type of pipe for their water transport systems, facilities can ensure the safe and efficient treatment of water while minimizing the risk of corrosion-related issues. With its proven track record of performance and durability, API Gas Line ERW Carbon Steel Pipe is a reliable choice for water treatment applications.

Comparison of Galvanized vs. Polyethylene Coated HSAW Carbon Steel Pipe for Casing in Construction Projects

API Gas Line ERW, Hsaw Carbon Steel Pipe with Galvanized/Polyethylene Coated for Casing/Water Treatment/UL Fire/Pile/Drilling/Construction

When it comes to construction projects that require the use of casing pipes, choosing the right material and coating is crucial. Two popular options for casing pipes are galvanized and polyethylene coated HSAW carbon Steel Pipes. Both options have their own set of advantages and disadvantages, and it is important to understand the differences between the two in order to make an informed decision.

Galvanized HSAW carbon steel pipes are coated with a layer of Zinc to protect the steel from corrosion. This coating provides excellent protection against rust and other forms of corrosion, making galvanized pipes ideal for outdoor applications where they will be exposed to the elements. Additionally, galvanized pipes are relatively easy to install and require minimal maintenance, making them a cost-effective option for many construction projects.

On the other hand, polyethylene coated HSAW carbon steel pipes are coated with a layer of polyethylene, which provides excellent protection against corrosion and abrasion. Polyethylene coating is also resistant to Chemicals and UV rays, making it a durable option for casing pipes that will be used in harsh environments. Additionally, polyethylene coated pipes are lightweight and flexible, making them easy to transport and install.

One of the main differences between galvanized and polyethylene coated HSAW carbon steel pipes is their level of corrosion resistance. While both coatings provide protection against corrosion, polyethylene coating is generally considered to be more durable and long-lasting than galvanized coating. This makes polyethylene coated pipes a better option for construction projects that require long-term protection against corrosion.

Another important factor to consider when choosing between galvanized and polyethylene coated HSAW carbon steel pipes is their cost. Galvanized pipes are typically more affordable than polyethylene coated pipes, making them a popular choice for budget-conscious construction projects. However, it is important to consider the long-term costs of maintenance and replacement when making this decision, as polyethylene coated pipes may ultimately be more cost-effective in the long run.

In terms of environmental impact, both galvanized and polyethylene coated HSAW carbon steel pipes have their own set of advantages and disadvantages. Galvanized pipes are made from recycled steel and can be recycled at the end of their lifespan, making them a sustainable option for construction projects. However, the process of galvanizing steel can be energy-intensive and may produce harmful emissions. On the other hand, polyethylene coated pipes are made from non-toxic materials and can be recycled, making them a more environmentally friendly option overall.

In conclusion, when it comes to choosing between galvanized and polyethylene coated HSAW carbon steel pipes for casing in construction projects, there are several factors to consider. Galvanized pipes are affordable and easy to install, making them a popular choice for many projects. However, polyethylene coated pipes offer superior corrosion resistance and durability, making them a better option for long-term protection. Ultimately, the decision between galvanized and polyethylene coated pipes will depend on the specific needs of the project and the budget constraints of the construction team.