Table of Contents

Benefits of Using API 5L X52/X60/X65/X70 SMLS Pipe Line Pipe for Oil and Gas Industry

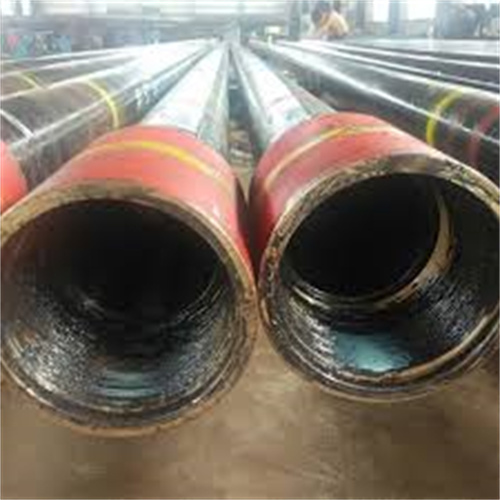

API 5L X52/X60/X65/X70 SMLS pipe line pipe is a type of seamless and welded steel pipe that is commonly used in the oil and gas industry. These pipes are designed to transport oil, gas, and other fluids under high pressure and extreme temperatures. There are several benefits to using API 5L X52/X60/X65/X70 SMLS pipe line pipe, making it a popular choice for many companies in the industry.

One of the main advantages of using API 5L X52/X60/X65/X70 SMLS pipe line pipe is its high strength and durability. These pipes are made from high-quality steel that is able to withstand the harsh conditions of the oil and gas industry. They are designed to resist corrosion, abrasion, and other forms of wear and tear, ensuring that they can last for many years without needing to be replaced.

In addition to their strength and durability, API 5L X52/X60/X65/X70 SMLS pipe line pipe is also known for its excellent performance in high-pressure and high-temperature environments. These pipes are able to handle the extreme conditions that are often present in oil and gas pipelines, making them a reliable choice for companies that need to transport fluids over long distances.

Another benefit of using API 5L X52/X60/X65/X70 SMLS pipe line pipe is its versatility. These pipes come in a variety of sizes and thicknesses, making it easy to find the right pipe for any application. Whether you need a small pipe for a local pipeline or a large pipe for a major oil and gas project, API 5L X52/X60/X65/X70 SMLS pipe line pipe can meet your needs.

Furthermore, API 5L X52/X60/X65/X70 SMLS pipe line pipe is easy to install and maintain. Because these pipes are seamless, they do not have any weld seams that can weaken over time. This makes them less prone to leaks and other issues that can arise with welded pipes. Additionally, the smooth surface of API 5L X52/X60/X65/X70 SMLS pipe line pipe makes it easy to clean and inspect, ensuring that it remains in good condition for years to come.

Overall, API 5L X52/X60/X65/X70 SMLS pipe line pipe offers a number of benefits for companies in the oil and gas industry. From its high strength and durability to its excellent performance in extreme conditions, these pipes are a reliable choice for Transporting fluids over long distances. With their versatility, ease of installation, and low maintenance requirements, API 5L X52/X60/X65/X70 SMLS pipe line pipe is a cost-effective solution for companies looking to improve their pipeline infrastructure.

Comparison Between Seamless and Welded API 5L X52/X60/X65/X70 Steel Pipes

API 5L X52/X60/X65/X70 steel pipes are widely used in the oil and gas industry for transporting fluids such as oil, gas, and water. These pipes are available in both seamless and welded forms, each with its own set of advantages and disadvantages. In this article, we will compare seamless and welded API 5L X52/X60/X65/X70 steel pipes to help you make an informed decision when choosing the right type of pipe for your project.

Seamless pipes are manufactured by piercing a solid billet of steel to create a hollow tube. This process results in a pipe with no seams or welds, making it stronger and more reliable than welded pipes. Seamless pipes are also more uniform in shape and size, which can help reduce the risk of leaks and failures. Additionally, seamless pipes are easier to inspect for defects, as there are no welds to inspect.

On the other hand, welded pipes are manufactured by welding together two or more pieces of steel to create a single pipe. While welded pipes are generally less expensive to produce than seamless pipes, they are also more prone to defects and failures. Welded pipes are more likely to have weak spots at the weld seams, which can Lead to leaks and other issues. Additionally, welded pipes are more difficult to inspect for defects, as the weld seams can be hidden or hard to access.

When it comes to strength and durability, seamless pipes are generally considered to be superior to welded pipes. Seamless pipes have a more uniform Grain structure, which can help prevent the formation of weak spots and cracks. This makes seamless pipes better suited for high-pressure and high-temperature applications, where strength and reliability are crucial. Welded pipes, on the other hand, are more prone to corrosion and stress corrosion cracking, which can reduce their lifespan and performance.

In terms of cost, welded pipes are typically less expensive to produce than seamless pipes. This is because the manufacturing process for welded pipes is simpler and requires less specialized equipment. However, the cost savings of welded pipes may be offset by the increased risk of defects and failures, which can lead to costly repairs and replacements Down the line. Seamless pipes may have a higher upfront cost, but their superior strength and reliability can help save money in the long run by reducing the need for maintenance and repairs.

In conclusion, both seamless and welded API 5L X52/X60/X65/X70 steel pipes have their own set of advantages and disadvantages. Seamless pipes are stronger, more reliable, and better suited for high-pressure and high-temperature applications, while welded pipes are less expensive to produce but more prone to defects and failures. When choosing between seamless and welded pipes, it is important to consider the specific requirements of your project and weigh the pros and cons of each type carefully. Ultimately, the decision between seamless and welded pipes will depend on factors such as cost, strength, durability, and performance.