Table of Contents

Benefits of Using API 5CT N80 L80 N80q P110 Casing Tubing Seamless Pipe

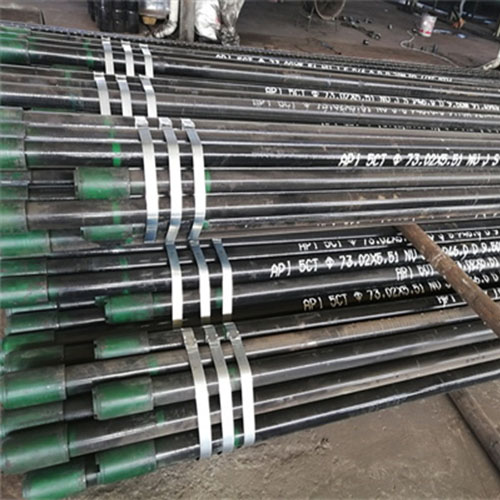

API 5CT N80 L80 N80q P110 casing tubing seamless pipe is a type of steel pipe used in the oil and gas industry for casing and tubing operations. This type of pipe is manufactured according to the American Petroleum Institute (API) 5CT standard, which sets specifications for the manufacturing and testing of casing and tubing used in the industry.

One of the main benefits of using API 5CT N80 L80 N80q P110 casing tubing seamless pipe is its high strength and durability. These pipes are made from high-quality steel that has been heat-treated to improve its mechanical properties, making it suitable for use in demanding oil and gas drilling operations. The seamless design of these pipes also ensures that they have a uniform wall thickness and are less prone to leaks or failures compared to welded pipes.

Another advantage of using API 5CT N80 L80 N80q P110 casing tubing seamless pipe is its resistance to corrosion. These pipes are typically coated with a protective layer to prevent rust and corrosion, which can extend their lifespan and reduce maintenance costs. This is particularly important in the oil and gas industry, where pipes are exposed to harsh environments and corrosive substances that can degrade their performance over time.

In addition to their strength and corrosion resistance, API 5CT N80 L80 N80q P110 casing tubing seamless pipe also offers excellent performance in high-pressure and high-temperature conditions. These pipes are designed to withstand the extreme pressures and temperatures encountered in oil and gas wells, making them ideal for use in challenging drilling environments. Their seamless construction ensures that they can maintain their integrity under these conditions, providing reliable performance when it matters most.

Furthermore, API 5CT N80 L80 N80q P110 casing tubing seamless pipe is easy to install and maintain, thanks to its uniform dimensions and smooth surface finish. This makes it easier for workers to handle and connect the pipes during drilling operations, reducing the risk of errors and delays. The seamless design of these pipes also minimizes the risk of leaks and failures, ensuring that drilling operations can proceed smoothly and efficiently.

Overall, API 5CT N80 L80 N80q P110 casing tubing seamless pipe offers a range of benefits for the oil and gas industry, including high strength, corrosion resistance, and excellent performance in challenging drilling conditions. Its seamless design and easy installation make it a reliable choice for casing and tubing operations, helping to improve efficiency and reduce maintenance costs. By choosing API 5CT N80 L80 N80q P110 casing tubing seamless pipe, companies can ensure that their drilling operations run smoothly and safely, leading to greater productivity and profitability in the long run.

Comparison of API 5CT N80 L80 N80q P110 Casing Tubing Seamless Pipe Grades

API 5CT is a standard specification for casing and tubing used in the oil and gas industry. It sets guidelines for the manufacturing and testing of these products to ensure they meet certain quality standards. Within the API 5CT specification, there are several grades of casing and tubing, each with its own unique properties and applications. In this article, we will compare four of the most commonly used grades: N80, L80, N80Q, and P110.

N80 is a medium-strength casing grade that is suitable for most oil and gas drilling applications. It has a minimum yield strength of 80,000 psi and a maximum yield strength of 110,000 psi. N80 is known for its high resistance to corrosion and excellent mechanical properties. It is often used in wells with moderate to high Levels of CO2 and H2S.

L80 is a higher-strength casing grade that is commonly used in more demanding drilling environments. It has a minimum yield strength of 80,000 psi and a maximum yield strength of 110,000 psi. L80 is heat-treated to improve its mechanical properties and is known for its excellent resistance to corrosion and cracking. It is often used in wells with high levels of CO2 and H2S.

N80Q is a modified version of the N80 grade that has been quenched and tempered to improve its mechanical properties. It has a minimum yield strength of 80,000 psi and a maximum yield strength of 110,000 psi. N80Q is known for its high resistance to corrosion and excellent toughness. It is often used in wells with high levels of CO2 and H2S.

P110 is a high-strength casing grade that is suitable for the most demanding drilling environments. It has a minimum yield strength of 110,000 psi and a maximum yield strength of 140,000 psi. P110 is heat-treated to improve its mechanical properties and is known for its excellent resistance to corrosion and cracking. It is often used in wells with high levels of CO2 and H2S.

When comparing these grades, it is important to consider the specific requirements of the well being drilled. N80 is a good all-around grade that is suitable for most applications, while L80, N80Q, and P110 are better suited for more demanding environments. L80 and N80Q are both heat-treated grades that offer improved mechanical properties, while P110 is a high-strength grade that is suitable for the most challenging drilling conditions.

In conclusion, the choice of casing and tubing grade will depend on the specific requirements of the well being drilled. N80 is a medium-strength grade that is suitable for most applications, while L80, N80Q, and P110 are better suited for more demanding environments. Each grade has its own unique properties and applications, so it is important to carefully consider the requirements of the well before selecting a grade. By choosing the right grade of casing and tubing, operators can ensure the success of their drilling operations and maximize the productivity of their wells.