Table of Contents

Advantages of Using API 11D Oilfield Hydraulic Retrievable Packer

API 11D Oilfield Hydraulic Retrievable Packer External Casing Packer is a crucial tool in the oil and gas industry. This packer is designed to isolate different zones in a wellbore, ensuring efficient production and preventing any unwanted fluid migration. There are several advantages to using this packer, making it a popular choice among oilfield operators.

One of the main advantages of the API 11D Oilfield Hydraulic Retrievable Packer is its versatility. This packer can be used in a wide range of wellbore conditions, including high-pressure and high-temperature environments. Its robust design and construction make it suitable for both onshore and offshore applications, providing operators with a reliable solution for their well completion needs.

In addition to its versatility, the API 11D Oilfield Hydraulic Retrievable Packer offers ease of installation and retrieval. The packer can be easily run in and set using hydraulic pressure, and it can be retrieved just as easily using a retrieval tool. This ease of installation and retrieval saves time and reduces operational costs, making it a cost-effective solution for oilfield operators.

Another advantage of the API 11D Oilfield Hydraulic Retrievable Packer is its durability. This packer is built to withstand the harsh conditions of the oilfield, including high pressures, temperatures, and corrosive fluids. Its robust construction ensures long-term reliability, reducing the need for frequent maintenance and replacement.

Furthermore, the API 11D Oilfield Hydraulic Retrievable Packer is designed for optimal performance. The packer features a high-quality sealing system that ensures a tight seal between the packer and the casing, preventing any fluid migration between different zones in the wellbore. This tight seal enhances well integrity and ensures efficient production, maximizing the overall productivity of the well.

Additionally, the API 11D Oilfield Hydraulic Retrievable Packer is designed for easy customization. Operators can choose from a range of options, including different sizes, materials, and configurations, to meet their specific well completion requirements. This customization allows operators to tailor the packer to their unique wellbore conditions, ensuring optimal performance and efficiency.

Overall, the API 11D Oilfield Hydraulic Retrievable Packer offers a range of advantages that make it a valuable tool for oilfield operators. Its versatility, ease of installation and retrieval, durability, optimal performance, and customization options make it a reliable and cost-effective solution for well completion needs. By choosing the API 11D Oilfield Hydraulic Retrievable Packer, operators can ensure efficient production, well integrity, and long-term reliability in their oil and gas operations.

How to Properly Install and Maintain an External Casing Packer for Oilfield Operations

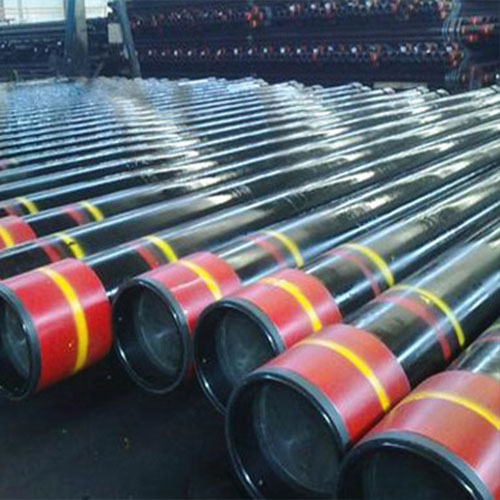

API 11D oilfield hydraulic retrievable packers are essential tools used in oilfield operations to isolate and control the flow of fluids in a wellbore. These packers are designed to create a seal between the casing and the tubing, preventing the migration of fluids between different zones in the well. One type of packer commonly used in oilfield operations is the external casing packer, which is installed on the outside of the casing string. In this article, we will discuss how to properly install and maintain an external casing packer for oilfield operations.

Proper installation of an external casing packer is crucial to ensure its effectiveness in isolating zones in the wellbore. Before installing the packer, it is important to inspect the packer components for any damage or defects. This includes checking the packer body, Slips, Seals, and setting mechanism for any signs of wear or corrosion. Any damaged components should be replaced before proceeding with the installation.

Once the packer components have been inspected and deemed to be in good condition, the packer can be installed on the casing string. The packer should be positioned at the desired depth in the wellbore and securely attached to the casing using the appropriate setting tools. It is important to follow the manufacturer’s instructions for setting the packer to ensure a proper seal is created between the casing and the tubing.

After the packer has been set, it is important to pressure test the packer to verify that it is holding pressure and creating a reliable seal. This can be done by applying pressure to the annulus between the casing and the tubing and monitoring for any pressure drops or leaks. If any issues are detected during the pressure test, the packer should be reset or replaced to ensure proper isolation of zones in the wellbore.

Proper maintenance of an external casing packer is essential to ensure its longevity and effectiveness in oilfield operations. Regular inspections should be conducted to check for any signs of wear or damage to the packer components. This includes inspecting the packer body, slips, seals, and setting mechanism for any corrosion, erosion, or deformation. Any damaged components should be replaced promptly to prevent any issues during well operations.

In addition to regular inspections, external casing packers should be periodically tested to ensure they are functioning properly. This can include conducting pressure tests to verify the packer’s ability to hold pressure and create a reliable seal. It is also important to monitor the packer’s performance during well operations to ensure it is effectively isolating zones in the wellbore.

In conclusion, proper installation and maintenance of an external casing packer are essential for successful oilfield operations. By following the manufacturer’s instructions for installation and conducting regular inspections and tests, operators can ensure that their packers are functioning properly and effectively isolating zones in the wellbore. By taking these steps, operators can minimize the risk of fluid migration and ensure the Safety and efficiency of their well operations.