Table of Contents

Benefits of Using Warm Mix Asphalt (WMA) in Road Construction

Warm Mix Asphalt (WMA) has gained popularity in recent years as a more sustainable and environmentally friendly alternative to traditional hot mix asphalt. By using additives or modifiers, WMA allows for lower mixing and compaction temperatures, reducing energy consumption and greenhouse gas emissions during the production process. In addition to its environmental benefits, WMA also offers several advantages in terms of performance and cost-effectiveness in road construction.

One of the key benefits of using WMA is its ability to improve workability and compaction of asphalt mixtures. The lower mixing temperatures of WMA reduce the viscosity of the asphalt binder, making it easier to work with and ensuring better coating and adhesion of aggregates. This results in a more uniform and durable pavement structure, with improved resistance to rutting and cracking. By using WMA modifiers from Chinese best manufacturers, road construction companies can achieve higher quality pavements that require less maintenance over time.

Another advantage of WMA is its ability to extend the paving season in colder climates. Traditional hot mix asphalt is typically produced and placed at temperatures above 300\\u00b0F, which can be challenging during the winter months. WMA, on the other hand, can be produced and placed at temperatures as low as 200-250\\u00b0F, allowing for longer paving seasons and increased flexibility in scheduling construction projects. This can help reduce delays and costs associated with weather-related disruptions, ultimately leading to faster project completion and improved overall efficiency.

In addition to its performance benefits, WMA also offers cost savings for road construction projects. The lower production temperatures of WMA result in reduced fuel consumption and lower energy costs, leading to significant savings in overall project expenses. By using WMA modifiers from Chinese best manufacturers, road construction companies can achieve these cost savings without compromising on the quality or durability of the pavement. This makes WMA a cost-effective solution for both public and private sector projects, helping to stretch limited budgets and maximize the value of infrastructure investments.

Furthermore, WMA can also help reduce the environmental impact of road construction activities. The lower production temperatures of WMA result in reduced emissions of greenhouse gases and other pollutants, helping to improve air quality and mitigate the effects of climate change. By using WMA modifiers from Chinese best manufacturers, road construction companies can contribute to a more sustainable and eco-friendly construction industry, aligning with global efforts to reduce carbon emissions and promote environmental stewardship.

| No. | Commodity Name |

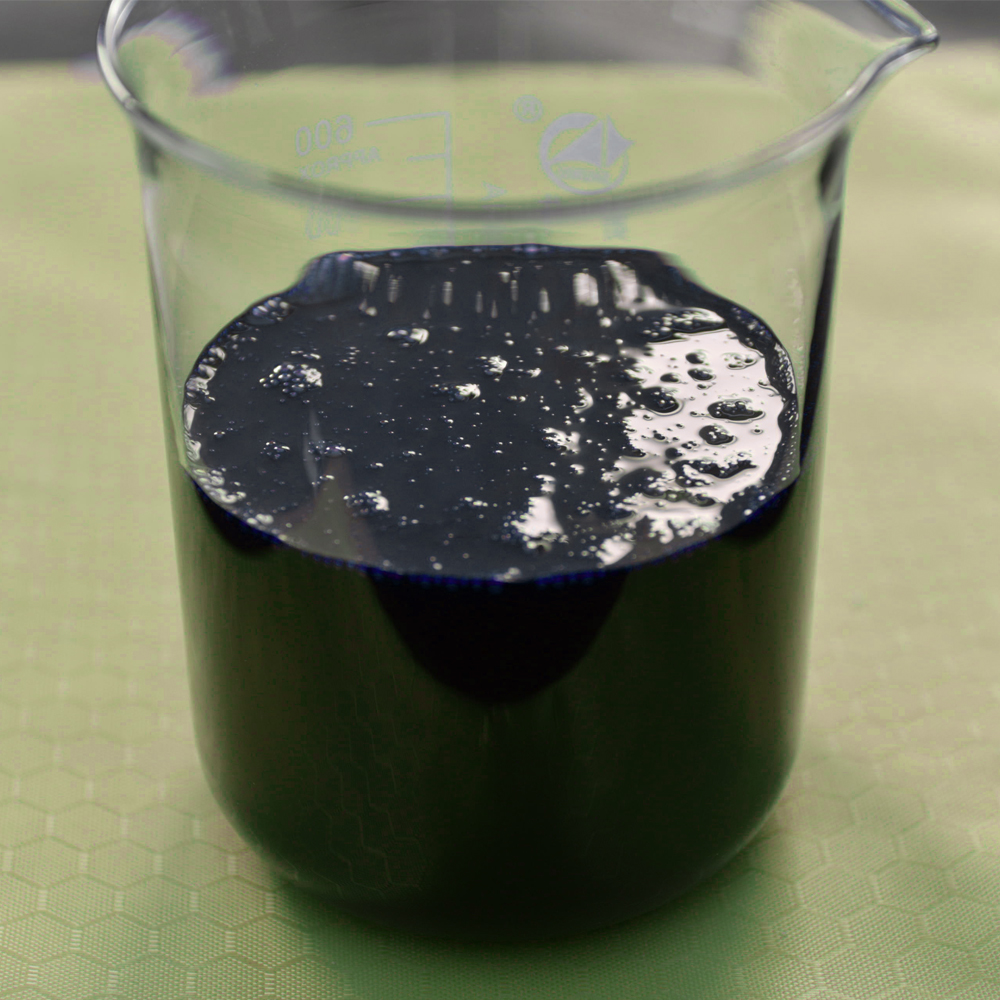

| 1 | Warm mix asphalt additive |

Overall, the benefits of using Warm Mix Asphalt (WMA) in road construction are clear. From improved workability and compaction to extended paving seasons and cost savings, WMA offers a range of advantages that make it an attractive option for infrastructure projects. By utilizing WMA modifiers from Chinese best manufacturers, road construction companies can achieve high-quality, durable pavements that are both environmentally friendly and cost-effective. As the industry continues to evolve and prioritize sustainability, WMA is poised to play a key role in shaping the future of road construction around the world.