Table of Contents

Benefits of Using a Spindle PCB Drilling Machine

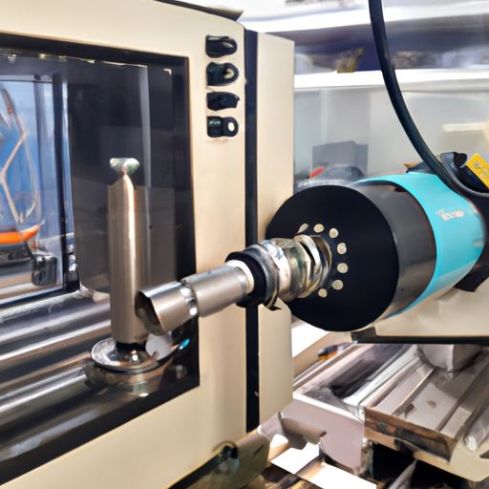

Spindle PCB Drilling Machines are essential tools in the manufacturing process of printed circuit Boards (PCBs). These machines are equipped with a spindle motor that provides the necessary power and precision for drilling holes in PCBs. The spindle motor in these machines typically has a power rating of 1.2 KW, which allows for efficient and accurate drilling operations. One of the key features of spindle PCB drilling machines is their automatic tool change capability, which enables seamless transitions between different Drill Bits without the need for manual intervention.

One of the primary benefits of using a spindle PCB drilling machine is the high level of precision that can be achieved. The spindle motor in these machines is designed to operate at high speeds while maintaining tight tolerances, ensuring that each hole drilled is accurate and consistent. This level of precision is crucial in the manufacturing of PCBs, where even minor errors can Lead to faulty connections and malfunctioning circuits.

Another advantage of using a spindle PCB drilling machine is the efficiency it brings to the manufacturing process. The automatic tool change feature allows for rapid switching between drill bits, reducing downtime and increasing productivity. This feature is particularly useful in high-volume production environments where time is of the essence. Additionally, the high-speed operation of the spindle motor ensures that drilling operations are completed quickly and efficiently, further enhancing productivity.

In addition to precision and efficiency, spindle PCB drilling machines also offer versatility in terms of the types of holes that can be drilled. These machines are capable of drilling holes of various sizes and shapes, allowing for the creation of complex PCB designs. Whether it’s a simple single-sided board or a multi-layered PCB with intricate circuitry, a spindle PCB drilling machine can handle the job with ease.

Furthermore, the use of a spindle PCB drilling machine can lead to cost savings in the long run. By automating the drilling process and reducing the risk of errors, these machines help minimize waste and rework, ultimately leading to lower production costs. Additionally, the high-speed operation of the spindle motor means that more PCBs can be produced in a shorter amount of time, further driving Down manufacturing costs.

Overall, the benefits of using a spindle PCB drilling machine are clear. From precision and efficiency to versatility and cost savings, these machines offer a range of advantages that can greatly enhance the manufacturing process of PCBs. Whether you’re a small-scale electronics manufacturer or a large production facility, investing in a spindle PCB drilling machine can help streamline your operations and improve the quality of your products. With their advanced features and capabilities, these machines are a valuable asset for any PCB manufacturing operation.

Overall, the benefits of using a spindle PCB drilling machine are clear. From precision and efficiency to versatility and cost savings, these machines offer a range of advantages that can greatly enhance the manufacturing process of PCBs. Whether you’re a small-scale electronics manufacturer or a large production facility, investing in a spindle PCB drilling machine can help streamline your operations and improve the quality of your products. With their advanced features and capabilities, these machines are a valuable asset for any PCB manufacturing operation.