Table of Contents

Pros and Cons of Using Piping Rail Conveying System for Beveling Machine

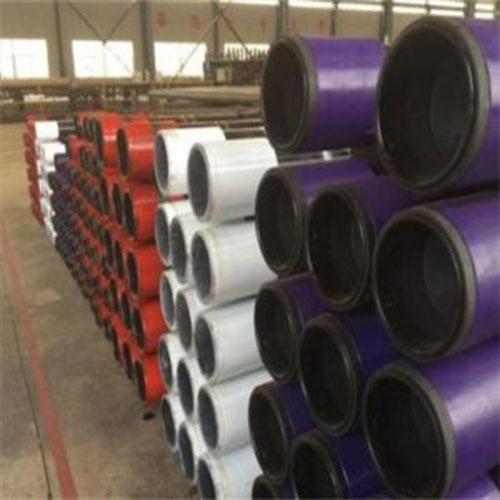

Piping rail conveying systems are a popular choice for Transporting materials in various industries, including the manufacturing sector. When it comes to beveling machines, using a piping rail conveying system can offer several advantages. However, like any technology, there are also some drawbacks to consider. In this article, we will explore the pros and cons of using a piping rail conveying system for a beveling machine.

One of the main advantages of using a piping rail conveying system for a beveling machine is its efficiency. These systems are designed to move materials quickly and smoothly from one point to another, which can help streamline the production process. This can result in increased productivity and reduced downtime, ultimately leading to cost savings for the company.

Additionally, piping rail conveying systems are highly customizable, allowing for easy integration with existing machinery and equipment. This flexibility makes it easier to adapt the system to meet the specific needs of the beveling machine, ensuring optimal performance and efficiency.

Another benefit of using a piping rail conveying system is its ability to handle heavy loads. Beveling machines can be quite large and heavy, requiring a robust conveying system to transport them safely and efficiently. Piping rail systems are designed to support heavy loads, making them an ideal choice for this application.

Furthermore, piping rail conveying systems are known for their reliability. These systems are built to withstand the rigors of industrial environments, ensuring consistent performance over time. This reliability can help minimize maintenance and repair costs, as well as reduce the risk of unexpected downtime.

On the other hand, there are some drawbacks to using a piping rail conveying system for a beveling machine. One potential downside is the initial cost of installation. Piping rail systems can be expensive to purchase and install, especially for larger machines or complex production lines. However, many companies find that the long-term benefits outweigh the upfront investment.

Another drawback is the potential for maintenance issues. While piping rail conveying systems are generally reliable, they can require regular maintenance to ensure optimal performance. This can include lubricating moving parts, replacing worn components, and addressing any issues that may arise during operation.

Additionally, piping rail systems can be less flexible than other types of conveying systems. Once installed, these systems are typically fixed in place and may not be easily reconfigured or moved to accommodate changes in production needs. This lack of flexibility can be a disadvantage for companies that require frequent adjustments to their production processes.

https://www.youtube.com/watch?v=kcGBRz7l738

In conclusion, using a piping rail conveying system for a beveling machine offers several advantages, including efficiency, customization, load capacity, and reliability. However, there are also some drawbacks to consider, such as the initial cost of installation, maintenance requirements, and lack of flexibility. Ultimately, the decision to use a piping rail conveying system will depend on the specific needs and priorities of the company. By weighing the pros and cons carefully, companies can determine whether this technology is the right choice for their beveling machine application.

How to Optimize Efficiency with Trolley Conveying System for Beveling Machine

In the manufacturing industry, efficiency is key to staying competitive and meeting customer demands. One way to optimize efficiency in the production process is by implementing a trolley conveying system for beveling machines. This system, also known as a piping rail system, can streamline the movement of materials and products throughout the Production Line, reducing manual handling and increasing productivity.

The trolley conveying system consists of a series of rails or tracks that guide trolleys carrying materials or products from one station to another. These trolleys can be manually operated or automated, depending on the specific needs of the production process. By using a trolley conveying system, manufacturers can eliminate the need for workers to manually transport materials, reducing the risk of injury and improving overall efficiency.

One of the key benefits of a trolley conveying system is its ability to optimize the flow of materials through the production line. By using a piping rail system, manufacturers can ensure that materials are delivered to the beveling machine in a timely manner, reducing downtime and increasing throughput. This can help to minimize bottlenecks in the production process and improve overall efficiency.

Another advantage of a trolley conveying system is its ability to reduce the risk of damage to materials or products. By using a trolley system, manufacturers can ensure that materials are transported safely and securely, minimizing the risk of damage during transit. This can help to improve product quality and reduce waste, ultimately leading to cost savings for the manufacturer.

In addition to improving efficiency and reducing the risk of damage, a trolley conveying system can also help to improve workplace Safety. By eliminating the need for workers to manually transport materials, manufacturers can reduce the risk of injuries and accidents on the production floor. This can help to create a safer working Environment for employees and improve overall morale in the workplace.

Overall, a trolley conveying system can be a valuable tool for manufacturers looking to optimize efficiency in their production process. By streamlining the movement of materials and products, reducing the risk of damage, and improving workplace safety, a trolley system can help manufacturers to increase productivity and reduce costs. Whether used in conjunction with a beveling machine or as part of a larger production line, a trolley conveying system can be a valuable investment for manufacturers looking to stay competitive in today’s fast-paced manufacturing industry.