Table of Contents

Benefits of Using 89mmx9.5m R2 API Nc38 13.30ppf Oil Drill Pipe Drill Rod

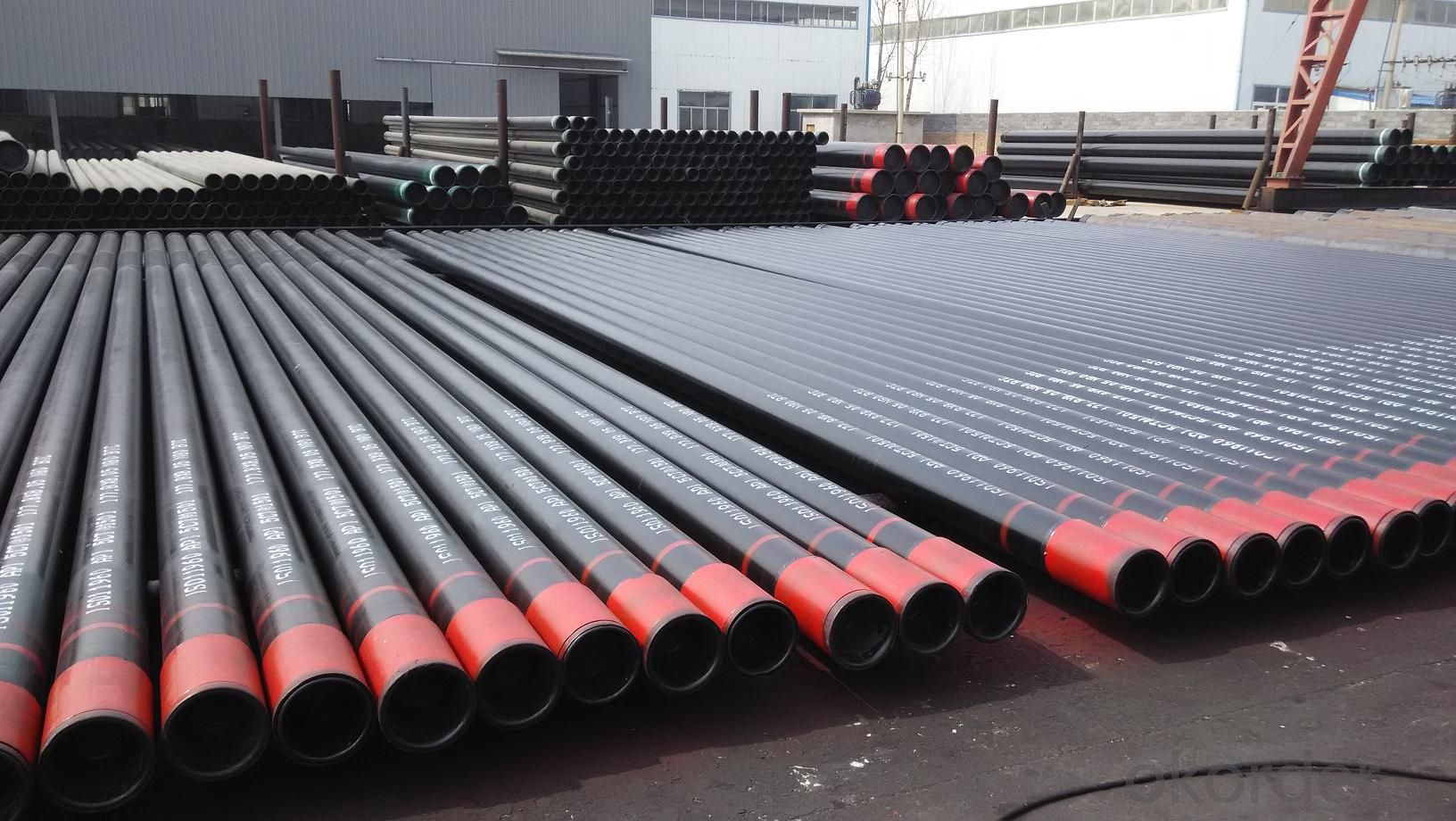

Oil drilling is a complex and demanding process that requires specialized equipment to extract oil from the ground efficiently. One essential piece of equipment used in oil drilling is the drill pipe drill rod. The 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is a popular choice among oil drilling companies due to its numerous benefits and advantages.

One of the key benefits of using the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is its durability and strength. Made from high-quality materials, this drill rod is designed to withstand the harsh conditions of oil drilling operations. Its robust construction ensures that it can handle the high pressures and temperatures encountered during drilling, making it a reliable and long-lasting tool for oil drilling companies.

https://www.youtube.com/watch?v=TFftwFKh3XMIn addition to its durability, the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is also highly efficient. Its design allows for smooth and efficient drilling, reducing the time and effort required to extract oil from the ground. This efficiency not only saves time and money for oil drilling companies but also helps to increase productivity and maximize output.

Furthermore, the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is versatile and can be used in a variety of drilling applications. Whether drilling in shallow or deep wells, this drill rod can adapt to different conditions and environments, making it a versatile and adaptable tool for oil drilling operations.

Another benefit of using the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is its compatibility with other drilling equipment. This drill rod is designed to work seamlessly with other drilling tools and equipment, ensuring smooth and efficient operation on the drilling site. Its compatibility with other equipment makes it easy to integrate into existing drilling systems, reducing downtime and increasing overall efficiency.

Moreover, the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is cost-effective. Its durability and efficiency help to reduce maintenance and replacement costs, saving money for oil drilling companies in the long run. Additionally, its versatility and compatibility with other equipment make it a valuable investment for oil drilling operations, providing a high return on investment over time.

Overall, the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod offers numerous benefits and advantages for oil drilling companies. From its durability and efficiency to its versatility and cost-effectiveness, this drill rod is a valuable tool for any oil drilling operation. By choosing the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod, oil drilling companies can improve their productivity, reduce costs, and maximize output, making it an essential piece of equipment for successful oil drilling operations.

Maintenance Tips for 89mmx9.5m R2 API Nc38 13.30ppf Oil Drill Pipe Drill Rod

Oil drill pipes are essential tools in the oil and gas industry, used for drilling wells to extract valuable resources from the earth. The 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is a common type of drill pipe that is widely used in drilling operations. To ensure the longevity and efficiency of this drill pipe, proper maintenance is crucial. In this article, we will discuss some important maintenance tips for the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod.

One of the most important maintenance tasks for oil drill pipes is regular inspection. Inspecting the drill pipe before and after each use can help identify any potential issues or damage that may affect its performance. Look for signs of wear and tear, such as cracks, dents, or corrosion. If any damage is found, it is important to address it promptly to prevent further deterioration.

In addition to visual inspection, it is also important to perform non-destructive testing (NDT) on the drill pipe regularly. NDT techniques such as ultrasonic testing or magnetic particle inspection can help detect internal flaws or defects that may not be visible to the naked eye. By conducting NDT, you can ensure the integrity of the drill pipe and prevent potential failures during drilling operations.

Another important maintenance tip for oil drill pipes is proper cleaning and storage. After each use, the drill pipe should be thoroughly cleaned to remove any dirt, debris, or drilling mud that may have accumulated on its surface. Use a cleaning solution and a brush to scrub the pipe clean, paying special attention to the threads and connections. Once cleaned, the drill pipe should be stored in a dry and well-ventilated area to prevent corrosion and rust.

Proper handling and transportation of the drill pipe are also crucial for its maintenance. When handling the drill pipe, avoid dropping or dragging it on the ground, as this can cause damage to the pipe. Use lifting equipment or tongs to move the drill pipe safely. During transportation, secure the drill pipe properly to prevent it from shifting or falling during transit.

Regularly lubricating the threads and connections of the drill pipe is another important maintenance task. Proper lubrication can help prevent galling and seizing of the threads, which can Lead to costly repairs or replacements. Use a high-quality Thread compound or grease to lubricate the threads before connecting the drill pipe.

Regularly lubricating the threads and connections of the drill pipe is another important maintenance task. Proper lubrication can help prevent galling and seizing of the threads, which can Lead to costly repairs or replacements. Use a high-quality Thread compound or grease to lubricate the threads before connecting the drill pipe.

Lastly, it is important to keep detailed records of the maintenance activities performed on the drill pipe. This includes inspection reports, NDT results, cleaning and lubrication records, as well as any repairs or replacements that have been done. By maintaining accurate records, you can track the maintenance history of the drill pipe and ensure that it is in good working condition.

In conclusion, proper maintenance of the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is essential to ensure its longevity and efficiency in drilling operations. By following these maintenance tips, you can prolong the life of the drill pipe and prevent costly downtime due to equipment failures. Remember to inspect the drill pipe regularly, clean and store it properly, handle and transport it with care, lubricate the threads, and keep detailed maintenance records. With proper maintenance, your oil drill pipe will continue to perform effectively and safely in drilling operations.

Common Issues and Solutions for 89mmx9.5m R2 API Nc38 13.30ppf Oil Drill Pipe Drill Rod

Oil drill pipes are essential components in the oil drilling process, as they are responsible for carrying drilling fluids and transmitting torque to the drill bit. The 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is a commonly used type of drill pipe in the industry. However, like any other equipment, these drill pipes can encounter various issues during operation. In this article, we will discuss some common issues that may arise with the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod and provide solutions to address these issues.

One common issue that drill pipe operators may encounter is thread galling. Thread galling occurs when the threads on the drill pipe become damaged or worn out, making it difficult to connect or disconnect the pipes. This can lead to delays in the drilling process and increased downtime. To prevent thread galling, it is important to properly maintain and inspect the threads on the drill pipe regularly. Using thread lubricants and ensuring that the threads are clean and free of debris can help prevent galling.

Another issue that drill pipe operators may face is corrosion. Corrosion can occur when the drill pipe is exposed to harsh drilling fluids or environmental conditions, causing the pipe to deteriorate over time. To prevent corrosion, it is important to use corrosion-resistant materials for the drill pipe and regularly inspect the pipe for signs of corrosion. Applying protective coatings or inhibitors can also help prevent corrosion and extend the lifespan of the drill pipe.

One of the most serious issues that can occur with drill pipes is fatigue failure. Fatigue failure happens when the drill pipe is subjected to repeated stress cycles, causing cracks to develop and eventually leading to pipe failure. To prevent fatigue failure, it is important to properly handle and store the drill pipe, avoid overloading the pipe, and inspect the pipe for signs of fatigue regularly. Using high-quality materials and following proper drilling practices can also help prevent fatigue failure.

In addition to these common issues, drill pipe operators may also encounter problems with bending or buckling of the drill pipe. Bending or buckling can occur when the drill pipe is subjected to excessive loads or improper handling, causing the pipe to deform and become unusable. To prevent bending or buckling, it is important to use the correct size and type of drill pipe for the drilling operation, avoid overloading the pipe, and handle the pipe with care during operation. Regular inspections and maintenance can also help identify any potential issues with bending or buckling early on.

Overall, the 89mmx9.5m R2 API Nc38 13.30ppf oil drill pipe drill rod is a reliable and durable piece of equipment that is essential for oil drilling operations. By being aware of common issues that may arise with the drill pipe and taking proactive measures to prevent these issues, drill pipe operators can ensure smooth and efficient drilling operations. Regular maintenance, proper handling, and adherence to best practices are key to maximizing the lifespan and performance of the drill pipe. By addressing issues promptly and implementing preventive measures, drill pipe operators can minimize downtime and maximize productivity in their drilling operations.