Table of Contents

Benefits of Using 3/16 Inch Diameter Steel Pipes in Auto Motoe Brake Systems

Steel pipes are an essential component in the construction of auto motoe brake systems. The 3/16 inch diameter steel pipes are commonly used in these systems due to their durability and strength. These pipes are available in both single wall and double wall seamless welded options, with a thickness of 0.7mm. In this article, we will explore the benefits of using 3/16 inch diameter steel pipes in auto motoe brake systems.

One of the key advantages of using 3/16 inch diameter steel pipes in auto motoe brake systems is their high strength and durability. These pipes are able to withstand high pressure and temperature fluctuations, making them ideal for use in brake systems where reliability is crucial. The seamless welded construction of these pipes ensures that they are leak-proof and resistant to corrosion, extending their lifespan and reducing the need for frequent maintenance.

In addition to their strength and durability, 3/16 inch diameter steel pipes offer excellent performance in terms of fluid flow. The smooth inner surface of these pipes allows for efficient flow of brake fluid, ensuring that the braking system operates smoothly and effectively. This is essential for maintaining the Safety and performance of the vehicle, as any restrictions or blockages in the brake lines can Lead to brake failure and accidents.

Another benefit of using 3/16 inch diameter steel pipes in auto motoe brake systems is their versatility and compatibility with different types of vehicles. These pipes can be easily customized to fit the specific requirements of different vehicle models, making them a versatile and cost-effective solution for brake system construction. Whether it is a compact car, a heavy-duty Truck, or a high-performance sports car, 3/16 inch diameter steel pipes can be tailored to meet the unique needs of each vehicle.

Furthermore, the use of 3/16 inch diameter steel pipes in auto motoe brake systems can help to improve the overall performance and efficiency of the braking system. The high-quality construction of these pipes ensures that they provide a reliable and consistent flow of brake fluid, leading to improved braking response and control. This is essential for ensuring the safety of the vehicle and its occupants, especially in emergency braking situations where quick and precise braking is crucial.

In conclusion, the benefits of using 3/16 inch diameter steel pipes in auto motoe brake systems are clear. These pipes offer high strength, durability, and performance, making them an ideal choice for constructing reliable and efficient brake systems. Their versatility and compatibility with different types of vehicles further enhance their appeal, making them a cost-effective solution for brake system construction. By choosing 3/16 inch diameter steel pipes for auto motoe brake systems, vehicle manufacturers and owners can ensure the safety, performance, and reliability of their vehicles on the road.

Comparison of Single Wall and Double Wall Seamless Welded Steel Pipes for Automobile Motor Car Chassis

When it comes to the construction of automobile motor car chassis, the choice of materials is crucial in ensuring the safety and performance of the vehicle. One of the key components in the chassis construction is the steel pipe used for the brake system. In this article, we will compare the use of single wall and double wall seamless welded steel pipes in automobile motor car chassis.

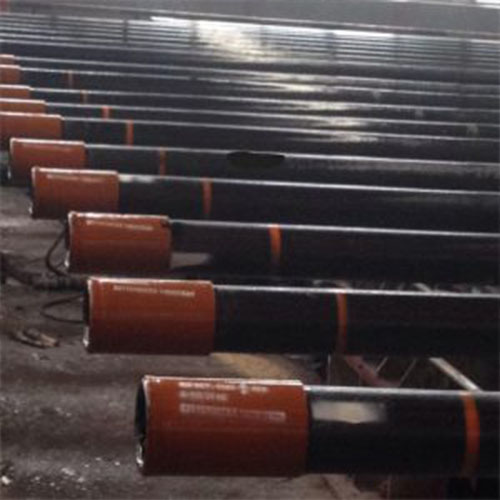

Single wall seamless welded steel pipes are made from a single piece of steel that is formed into a pipe through a seamless welding process. These pipes are known for their high strength and durability, making them ideal for use in automobile motor car chassis. The 3/16 inch diameter and 0.7mm thickness of these pipes provide the necessary structural support for the chassis, while also allowing for flexibility and ease of installation.

On the other hand, double wall seamless welded steel pipes consist of two layers of steel that are welded together to form a pipe. These pipes offer added strength and protection against corrosion, making them a popular choice for automobile motor car chassis. The 4.76 inch diameter of these pipes provides increased stability and rigidity, which is essential for maintaining the structural integrity of the chassis under heavy loads and harsh driving conditions.

In terms of performance, both single wall and double wall seamless welded steel pipes offer excellent durability and resistance to wear and tear. However, the double wall pipes provide an added layer of protection against external elements, such as moisture and debris, which can help prolong the lifespan of the chassis and ensure optimal performance over time.

When it comes to installation, single wall seamless welded steel pipes are generally easier to work with due to their lighter weight and flexibility. This makes them a preferred choice for manufacturers looking to streamline the production process and reduce costs. On the other hand, double wall seamless welded steel pipes may require more specialized equipment and expertise for installation, but they offer added peace of mind in terms of durability and protection.

In conclusion, both single wall and double wall seamless welded steel pipes have their own unique advantages and considerations when it comes to their use in automobile motor car chassis. The choice between the two will ultimately depend on the specific requirements of the vehicle and the desired level of performance and protection. Whether you opt for the strength and durability of single wall pipes or the added protection of double wall pipes, you can rest assured that your automobile motor car chassis will benefit from the use of high-quality steel pipes in its construction.